Prefabricated concrete-filled steel tube frame-shear wall and construction method thereof

A technology of steel pipe concrete and prefabricated steel pipes, applied to walls, building components, buildings, etc., to achieve the effects of ensuring construction quality, reducing labor intensity and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] The prefabricated steel pipe concrete frame shear wall described in this embodiment relates to an integral prefabricated steel pipe concrete frame shear wall and a split prefabricated steel pipe concrete frame shear wall.

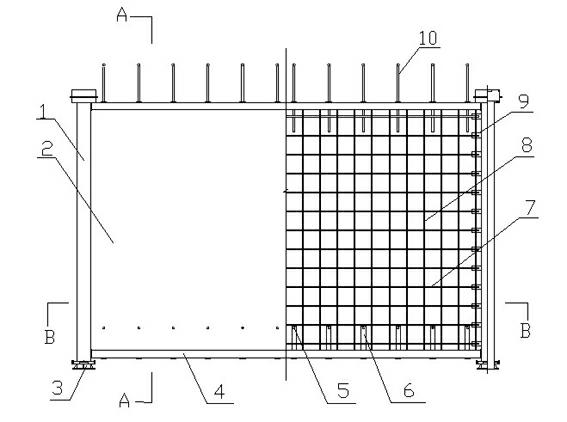

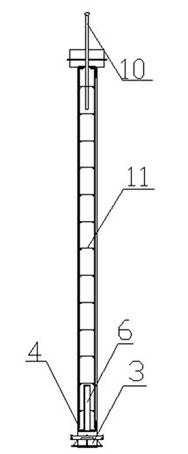

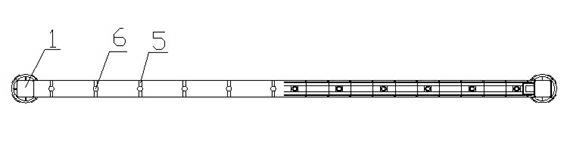

[0031] see figure 1 , figure 2 , image 3 , the shear wall panel 2 of the integral prefabricated steel pipe concrete frame shear wall is an integral wall piece, and the shear wall panel 2 is equipped with a steel mesh sheet composed of horizontally distributed steel bars 7 and longitudinally distributed steel bars 8 . Tension ribs 11 are provided between the sheets, and angle steel angle guards 4 are provided along the entire length of the upper and lower edges of the shear wall panels 2. A vertical connecting rib sleeve 6 is reserved at the lower edge, and a grouting hole 5 communicating with the end of the vertical con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com