Sunlight plate connection component applied to roof sunlight plate system

A technology for connecting components and sunshine boards, which is applied in the field of sunshine rooms, can solve problems such as inability to eliminate, waste, increase construction costs, etc., and achieve the effect of saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

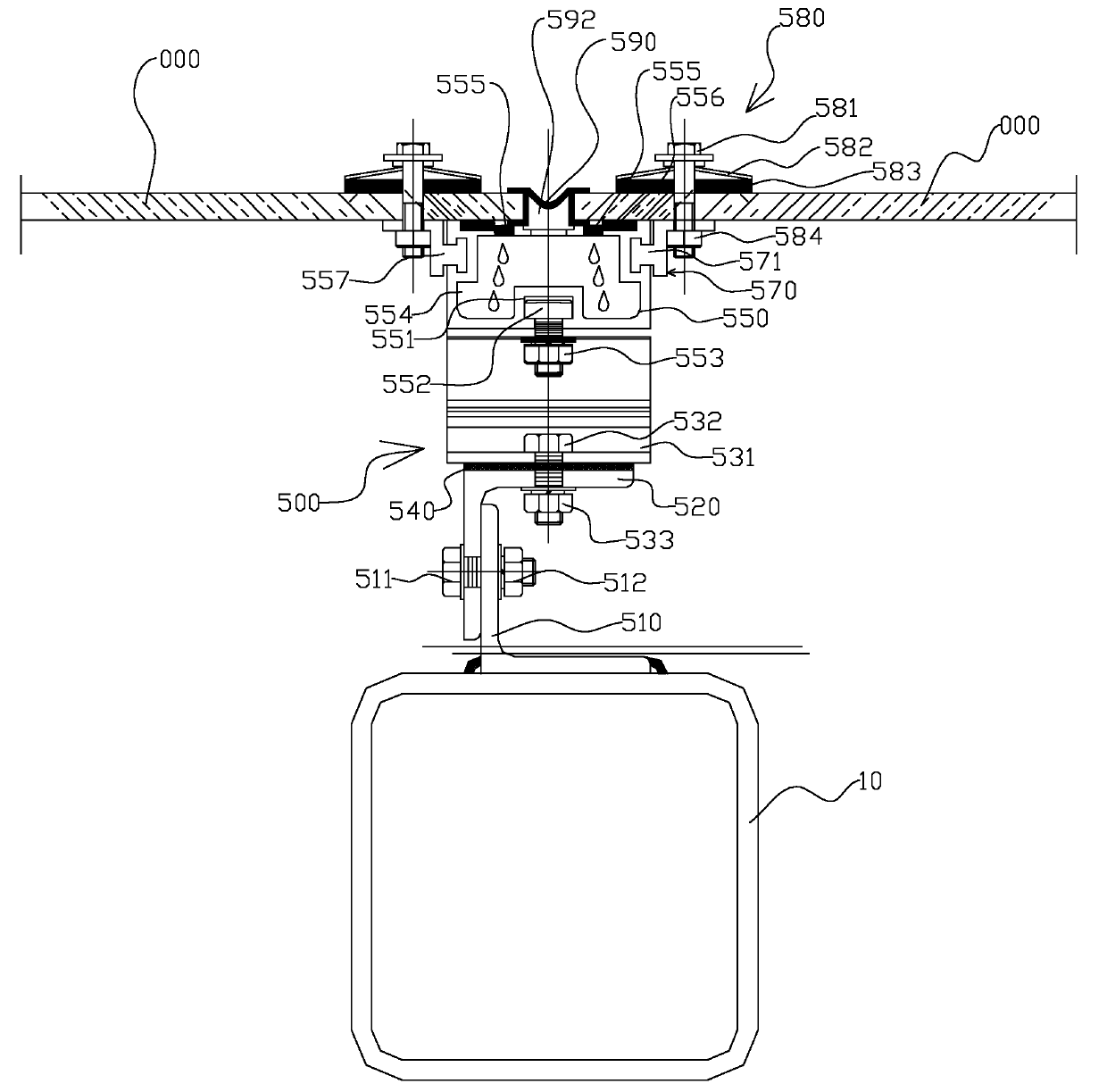

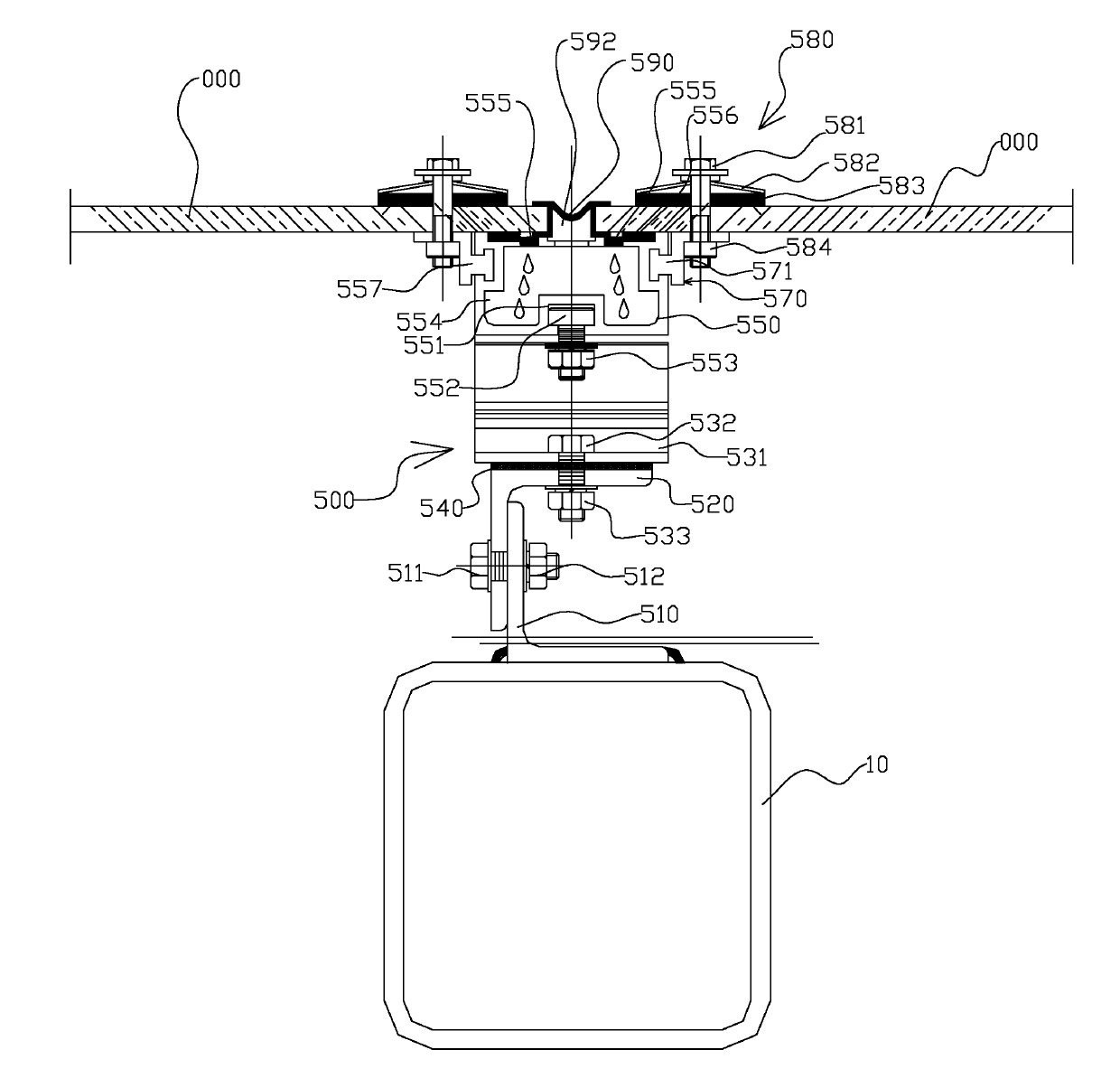

[0016] see figure 1 , the solar panel connection member 500 shown in the figure comprises the lower angle steel 510 welded on the square steel pipe purlin 10 in the support structure and the upper angle steel 520 fixed on the lower angle steel 510 by bolts 511 and nuts 512, the upper and lower angle steels 520, 510 forms an angle steel support.

[0017] The underboard sliding bearing 530 is a profile, and the bottom surface of the underboard sliding bearing 530 is provided with an underboard sliding groove 531 extending along the underboard sliding bearing 530. The length of the underboard sliding groove 531 is the same as that of the board The lower slide supports 530 are equal in length. Insert the head of the bolt 532 into the sliding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com