Manifold system for sand blender

A technology of manifold system and sand mixing equipment, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of single operation mode and inconvenient construction layout, so as to improve work efficiency and highlight substantive features , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

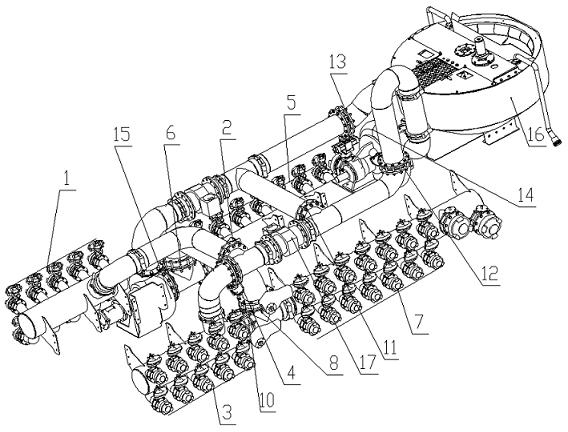

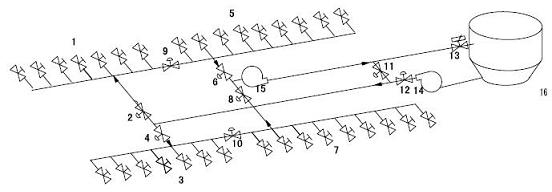

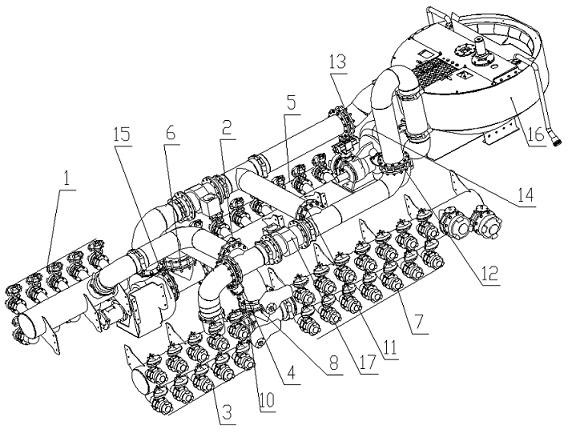

[0014] Example 1, see figure 1 , 2 , processed into a suction header welding assembly and a discharge header welding assembly, install the first butterfly valve 1, the fifth butterfly valve 5, and the ninth butterfly valve with pneumatic head devices on the connecting flange of the suction header welding assembly 9, wherein the fifth butterfly valve 5 and the first butterfly valve 1 need to be N according to the design, N is greater than or equal to 1, and N is a positive integer, and the third butterfly valve with a pneumatic head device is installed on the connecting flange of the discharge header welding assembly. Butterfly valve 3, seventh butterfly valve 7 and tenth butterfly valve 10, wherein the number of seventh butterfly valve 7 and third butterfly valve 3 is N according to the design requirements, N is greater than or equal to 1, and N is a positive integer, and the ninth butterfly valve 9 and the tenth butterfly valve 10 are respectively Located on the connecting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com