Gearbox for corn harvester for pulling seedlings and cutting stalks

A technology for corn harvesters and gearboxes, which is applied to mechanical equipment, automatic clutches, gear transmissions, etc., can solve the problems of high energy consumption, gear overload breakage, low efficiency, etc., and achieve the effect of compact structure and excellent working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

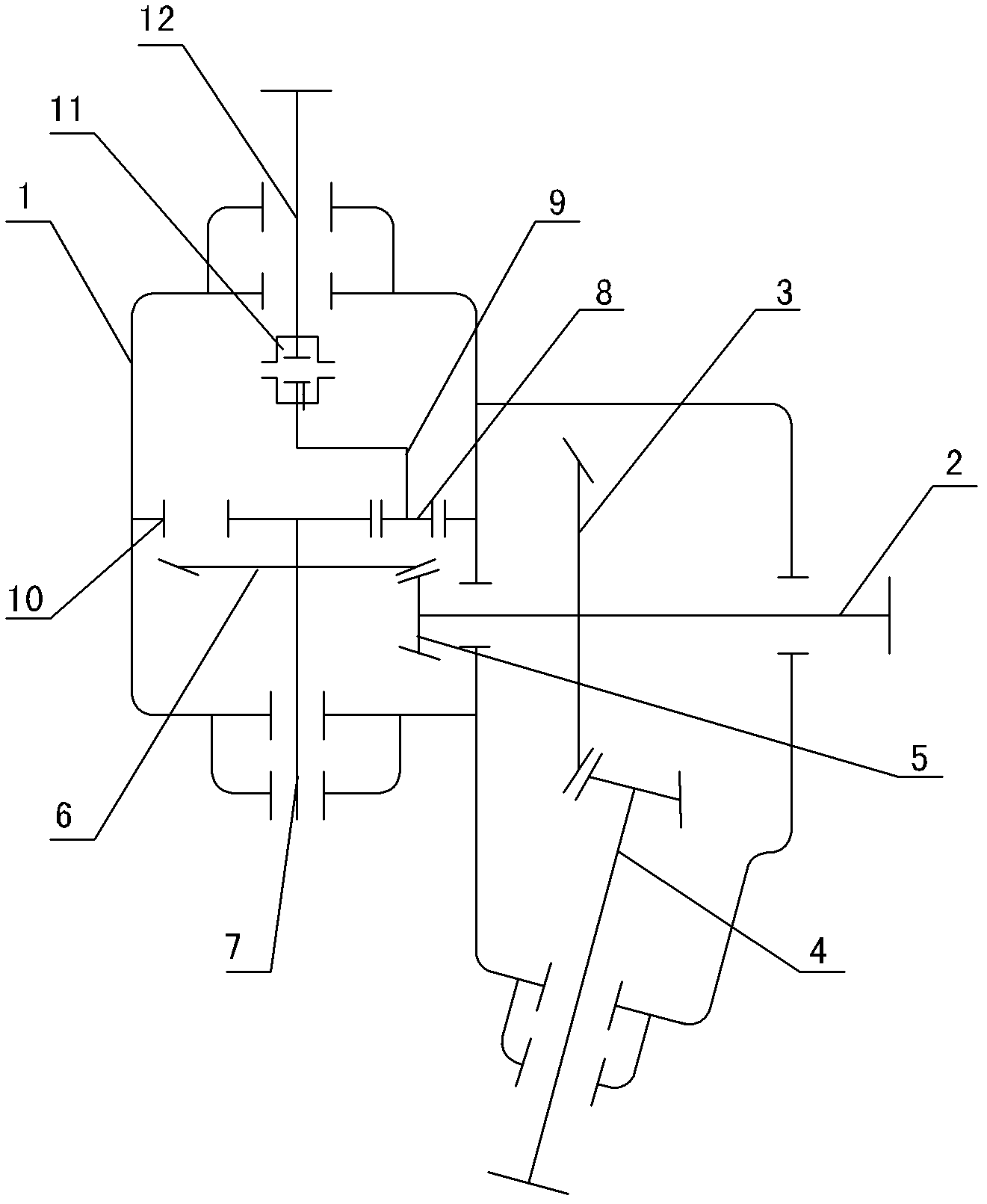

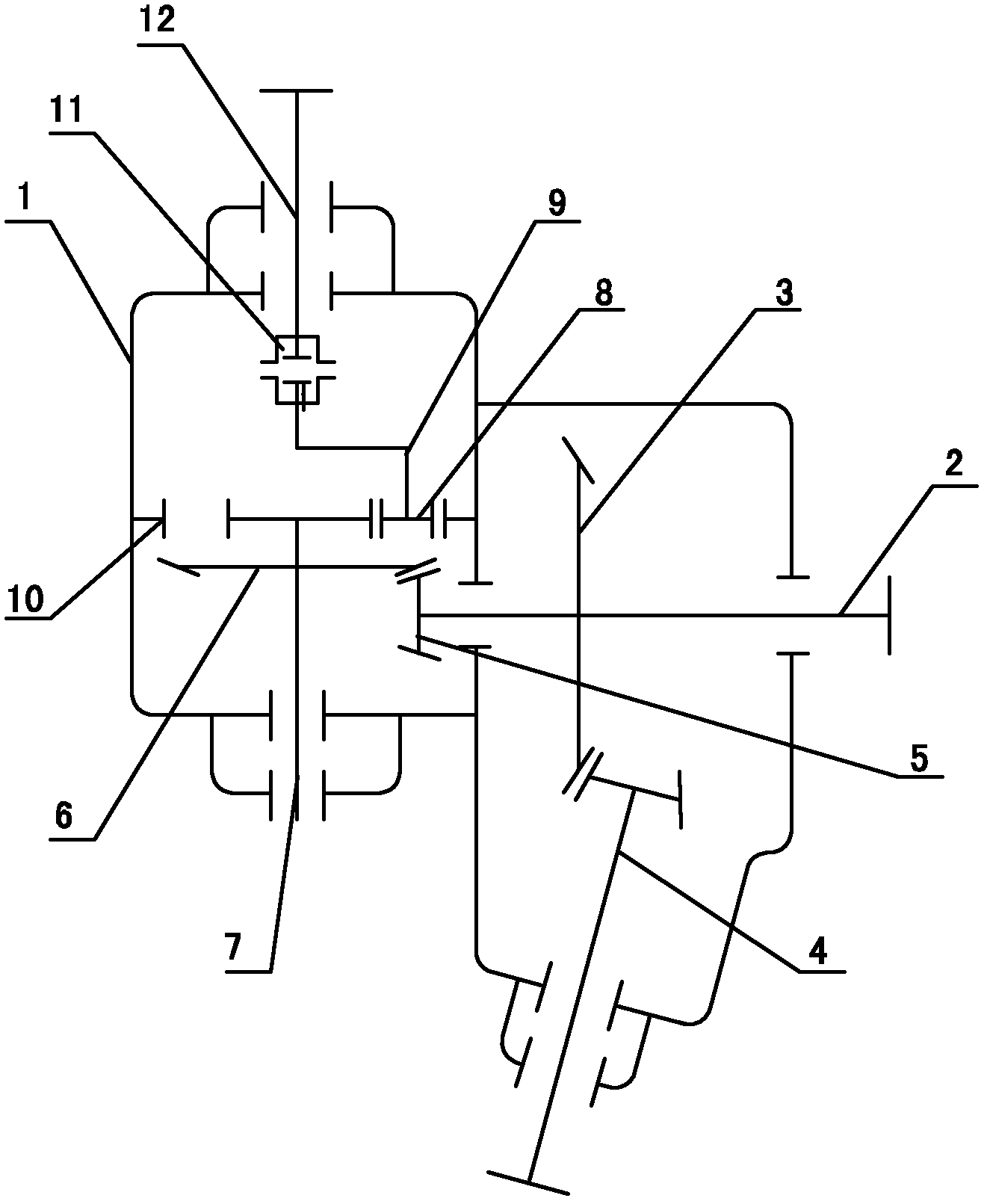

[0014] exist figure 1 In the shown embodiment: comprise box body 1 and be arranged on the power input shaft 2 on the box body 1, have set up chopping input bull gear 3, chopping power output gear shaft 4, reeling grain input pinion 5, are equipped with The sun gear shaft 7 of the bull gear 6, the planet gear shaft 9 equipped with the planet gear 8, the inner ring gear 10 of the gearbox, the pin type safety clutch 11 and the reeling power output shaft 12, wherein the shredding input bull gear 3 is fixedly installed on the power input On the shaft 2, and mesh with the shredding power output gear shaft 4, the angle between the shredding power output gear shaft 4 and the power input shaft 2 is 75°; It meshes with the large gear 6; the three planetary gears 8 are located between the sun gear shaft 7 and the gearbox ring gear 10, and mesh with the sun gear shaft 7 and the gearbox ring gear 10 respectively; the other end of the planet gear shaft 9 is fixed on the safety clutch The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com