Method for paving heating carbon fiber composite electro-thermal materials laid under cement screed-coat

A technology of composite materials and electrothermal materials, which is applied in the laying field of carbon fiber low-temperature composite electrothermal materials, can solve problems such as potential safety hazards, easily corroded heating elements, strong corrosion, etc., to ensure life safety, solve easily damaged, and solve easily corroded problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] According to the claims of the present invention and the contents disclosed in the summary of the invention, the technical solution of the present invention is specifically described as follows.

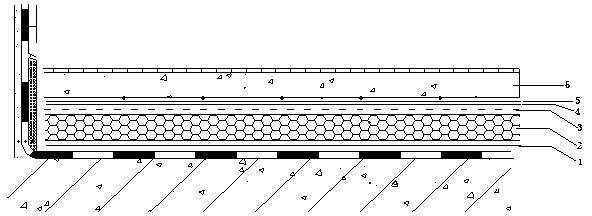

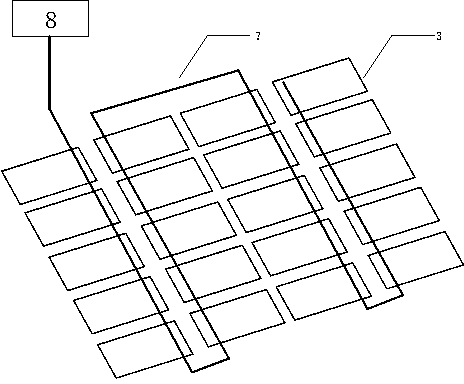

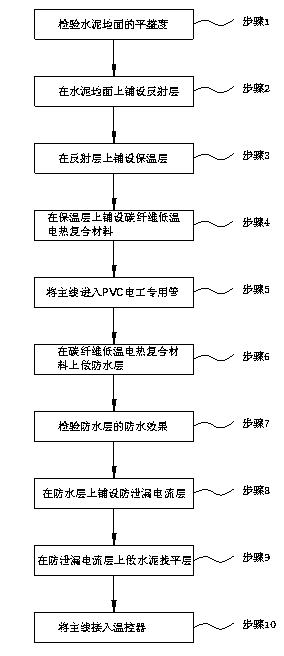

[0036] Please see attached figure 1 As shown, a pavement method of the heating carbon fiber composite electrothermal material laid under the cement leveling layer of the present invention includes a reflective layer 1, an insulation layer 2, a carbon fiber low-temperature electrothermal composite material 3, a waterproof layer 4, an anti-leakage current layer 5 and cement leveling layer 6; the reflective layer 1, thermal insulation layer 2, carbon fiber low-temperature electrothermal composite material 3, waterproof layer 4, anti-leakage current layer 5 and cement leveling layer 6 are sequentially laid on the cement floor; the carbon fiber low-temperature electrothermal composite The material 3 can be a flat heating element for heating.

[0037] In order to ensure the constru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com