Air inlet grille structure for indoor unit of cabinet air-conditioner

A technology of air intake grille and indoor unit, applied in the direction of airflow control components, etc., can solve the problems of increasing indoor fan motor load, affecting the overall performance of the machine, and long assembly time, reducing mold development, reducing processing costs, and saving The effect of installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

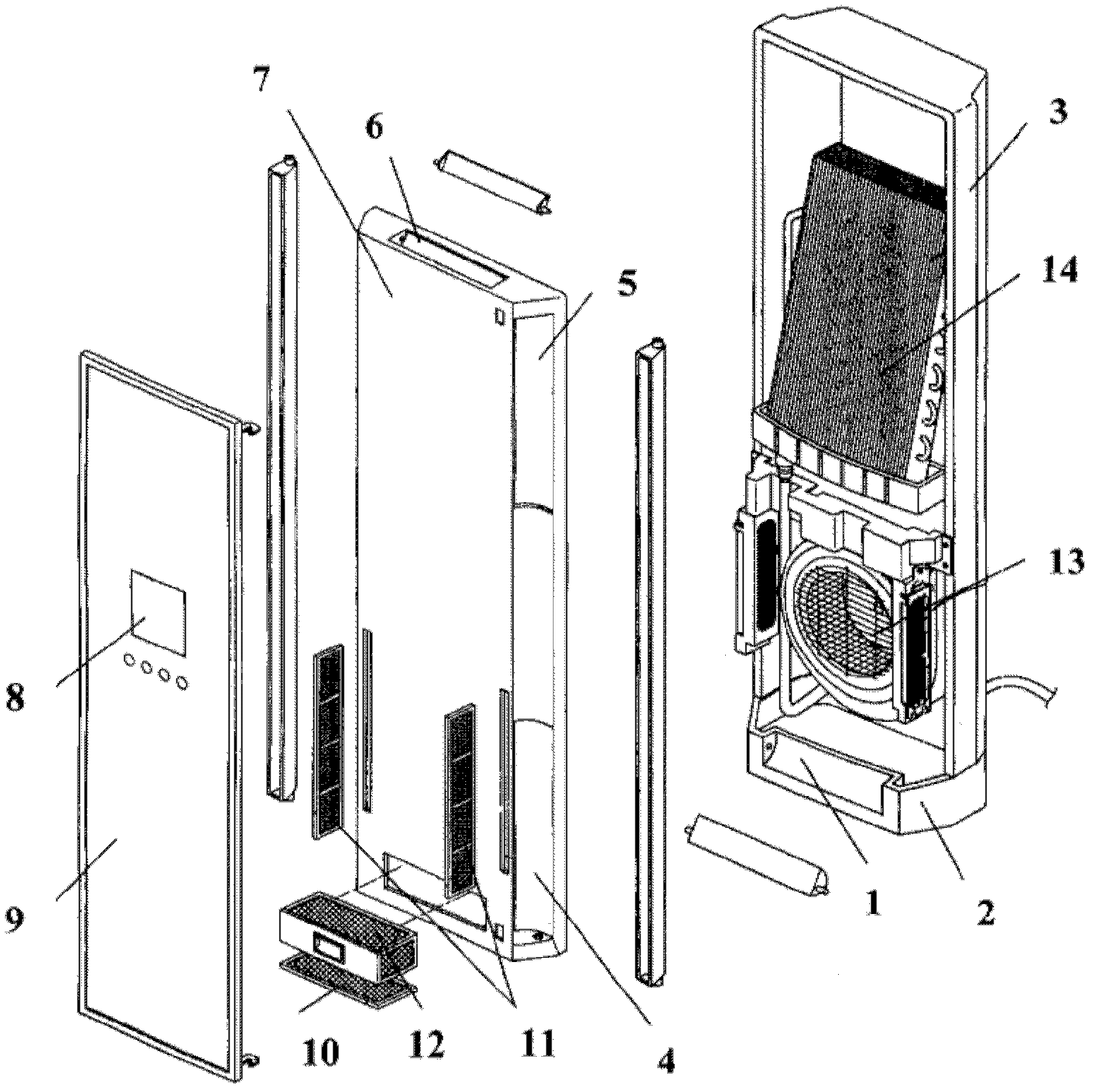

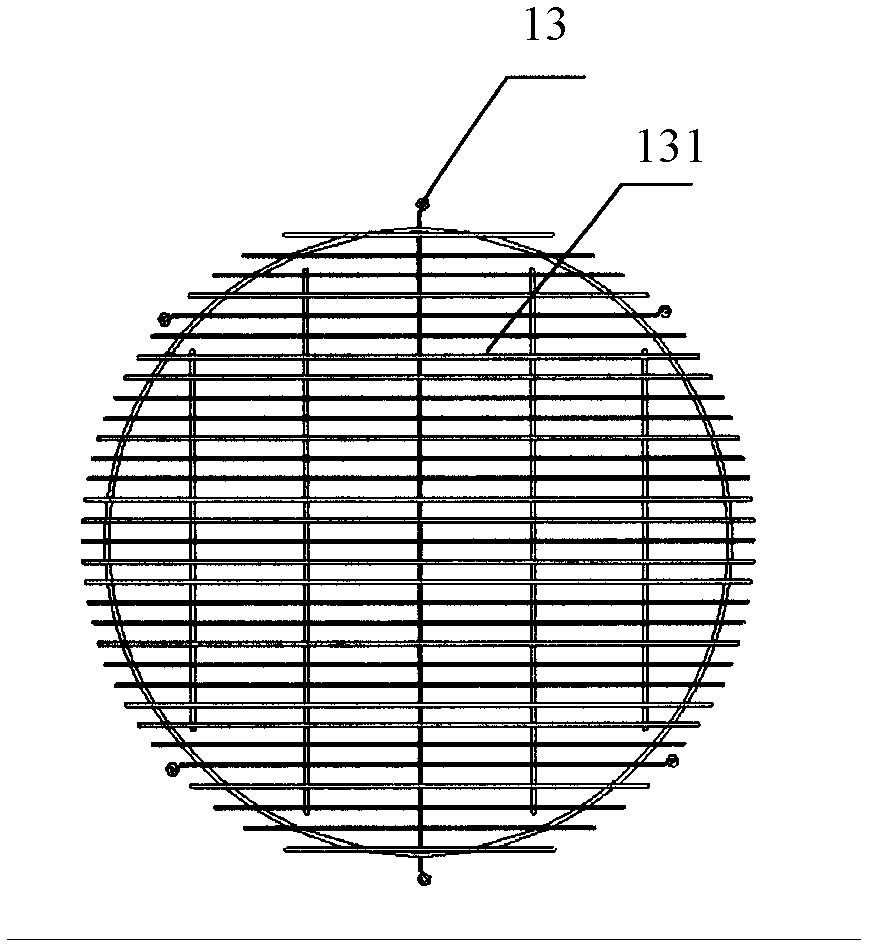

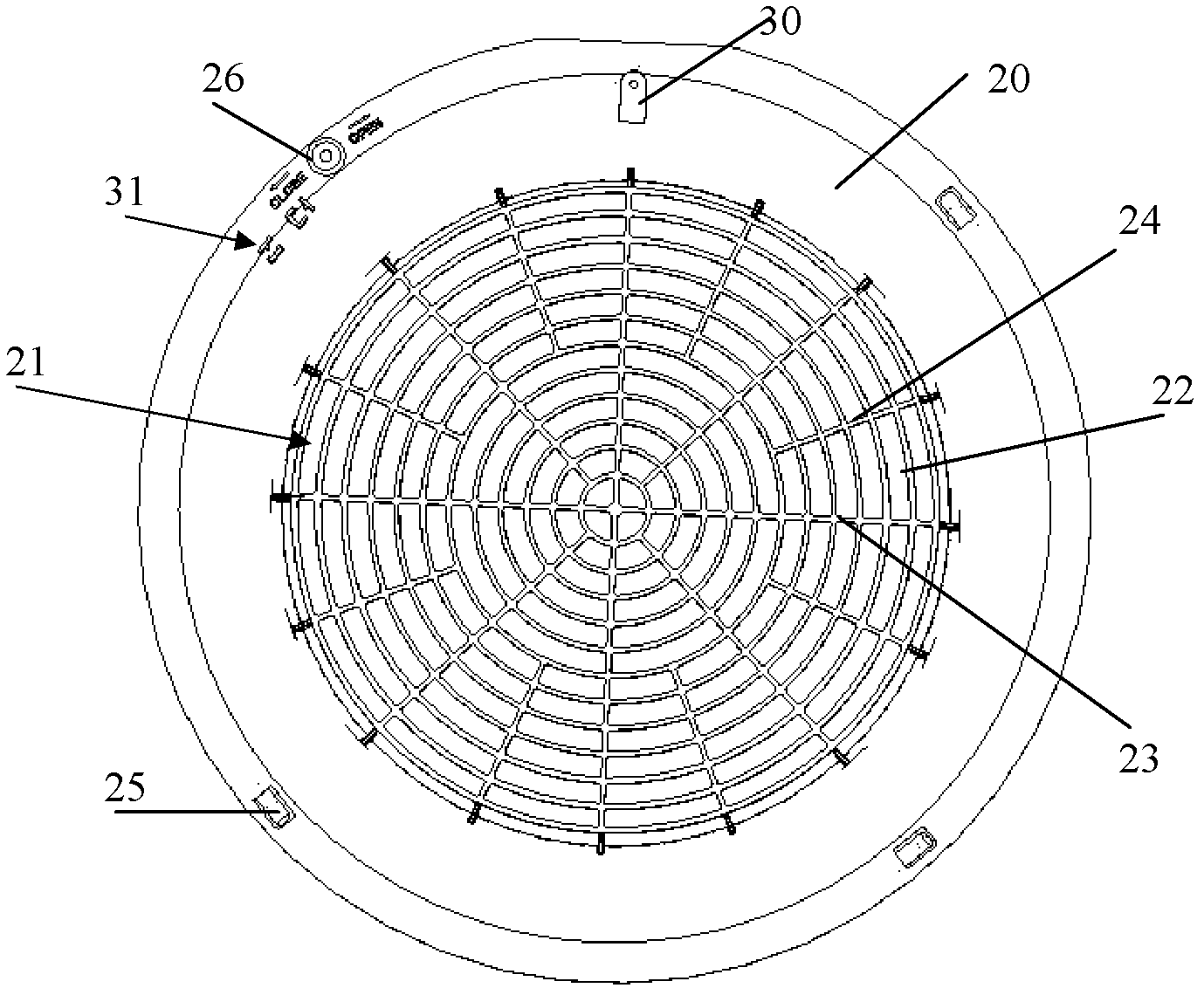

[0018] The indoor unit of the cabinet-type air conditioner of the present invention mainly includes a base that constitutes the external structure of the bottom surface of the indoor unit, and the front end is recessed to form a base with a lower air inlet; The lower part and the upper part are respectively provided with side air inlets and side air outlets, and the top surface is provided with a front frame with top air outlets; it is installed on the front surface of the front frame, and the front panel with a display window is arranged in the middle; it is set on The lower suction grill above the lower air inlet of the base; the side suction grills respectively arranged on the two side air inlets; the filter arranged on the upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com