Defroster of refrigerator

A technology for refrigerators and condensers, applied in the field of defrosting devices, can solve the problems of reduced efficiency of refrigerators, blocked heat exchange of refrigerator evaporators, and reduced heat exchange efficiency of evaporators, and achieves small temperature fluctuations in the box, low power, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

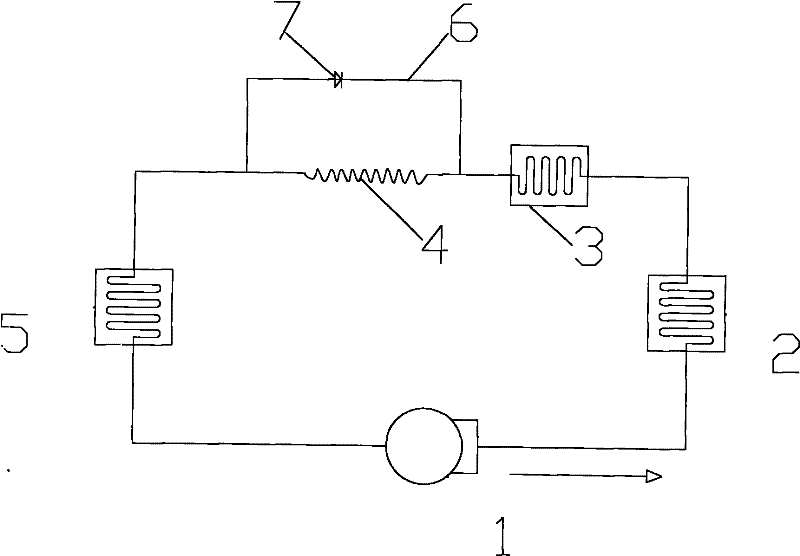

[0021] figure 1 Middle 1 is the refrigerator compressor, 2 is the left condenser of the refrigerator, 3 is the right condenser of the refrigerator, 4 is the capillary tube, 5 is the refrigerator evaporator, 6 is the pipe, and 7 is the valve. In this embodiment, one end of the pipe 6 is connected to the left condenser outlet, the valve 7 is connected to the pipe 6, and the other end of the pipe 6 is connected to the evaporator inlet; when defrosting is performed, the valve 7 is opened, and the pipe 6 will Capillary 4 is short-circuited. When the compressor is turned on, the refrigerant flows out of the right condenser 3 and then enters the evaporator 5 through the pipe 6. Since the pipeline 6 balances the pressure of the evaporator and the condenser, the inlet pressure of the compressor is not much different from the outlet pressure, and the compression ratio of the compressor is small, so the compression work of the compressor is also small. The compressor is like a pump to ma...

Embodiment 2

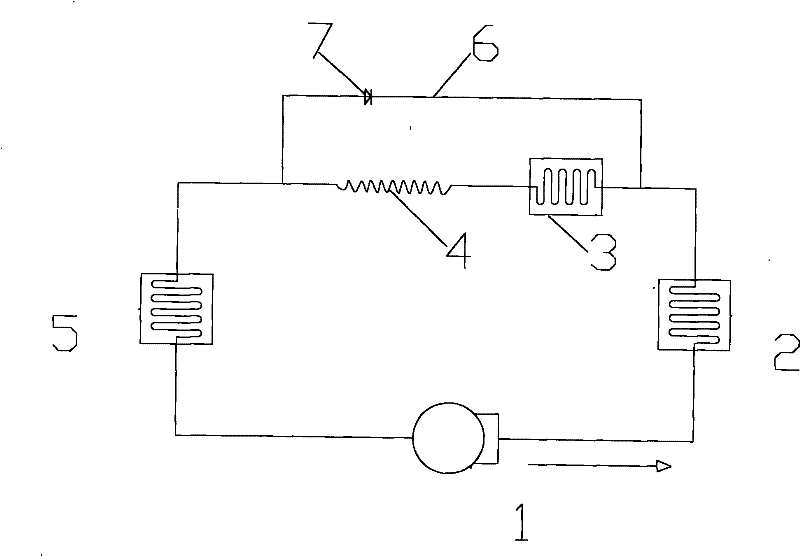

[0023] figure 2 Middle 1 is the refrigerator compressor, 2 is the left condenser of the refrigerator, 3 is the right condenser of the refrigerator, 4 is the capillary tube, 5 is the refrigerator evaporator, 6 is the pipe, and 7 is the valve. The difference between this embodiment and Embodiment 1 is that the inlet end of the pipe in this embodiment is connected with the outlet of the left condenser of the refrigerator, while the inlet end of the pipe in Embodiment 1 is connected with the outlet of the right condenser of the refrigerator.

Embodiment 3

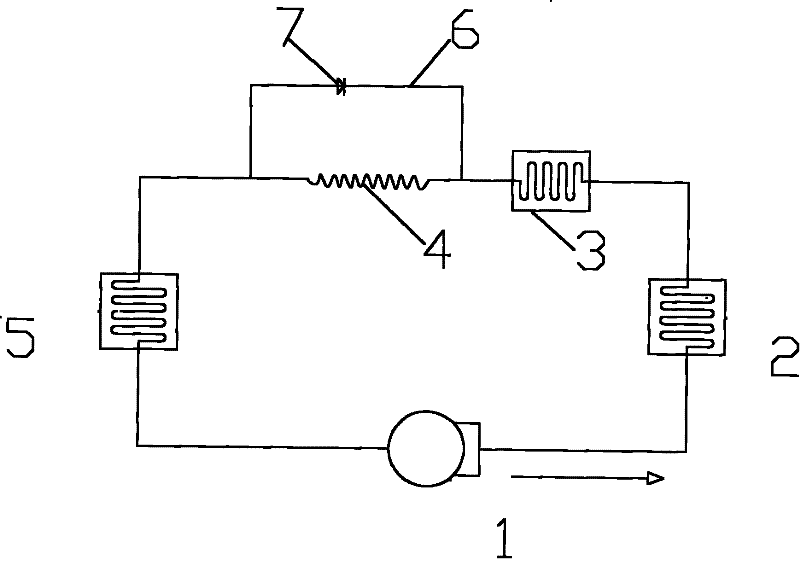

[0025] The refrigerator in this embodiment is a direct-cooling refrigerator. The refrigerator evaporator has a refrigerator compartment evaporator and a freezer compartment evaporator. In this embodiment, one end of the pipe with a valve is connected to the outlet of the refrigerator condenser, and the other end is connected to the refrigerator compartment evaporator. The inlet of the device is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com