High-accuracy non-contact waste gas recirculation valve position sensor

An exhaust gas recirculation valve, non-contact technology, applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of exhaust gas recirculation valve position sensor failure, difficult control of output linearity, dust and water vapor sensitivity, etc. Achieve the effects of improved production efficiency, high-precision linear output characteristics, accurate and more stable output signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

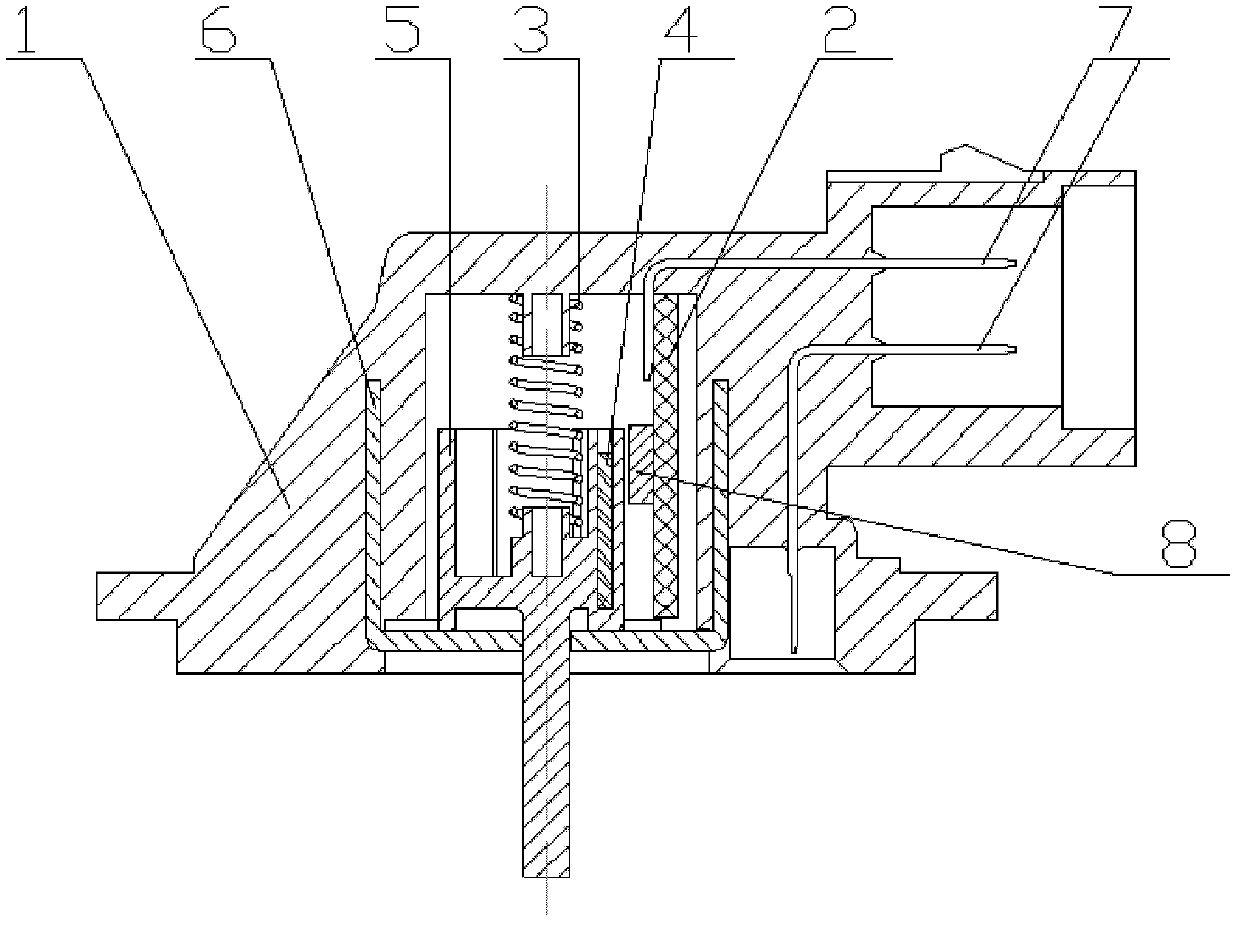

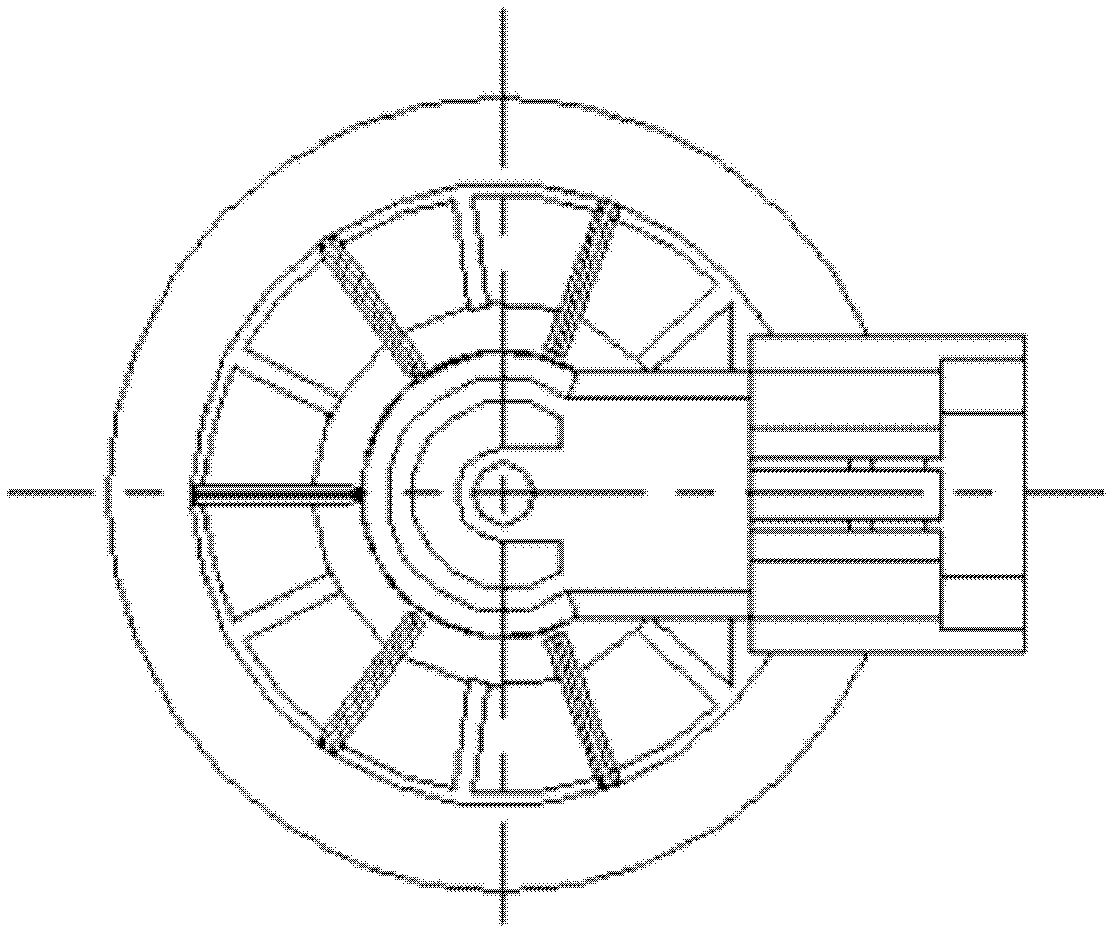

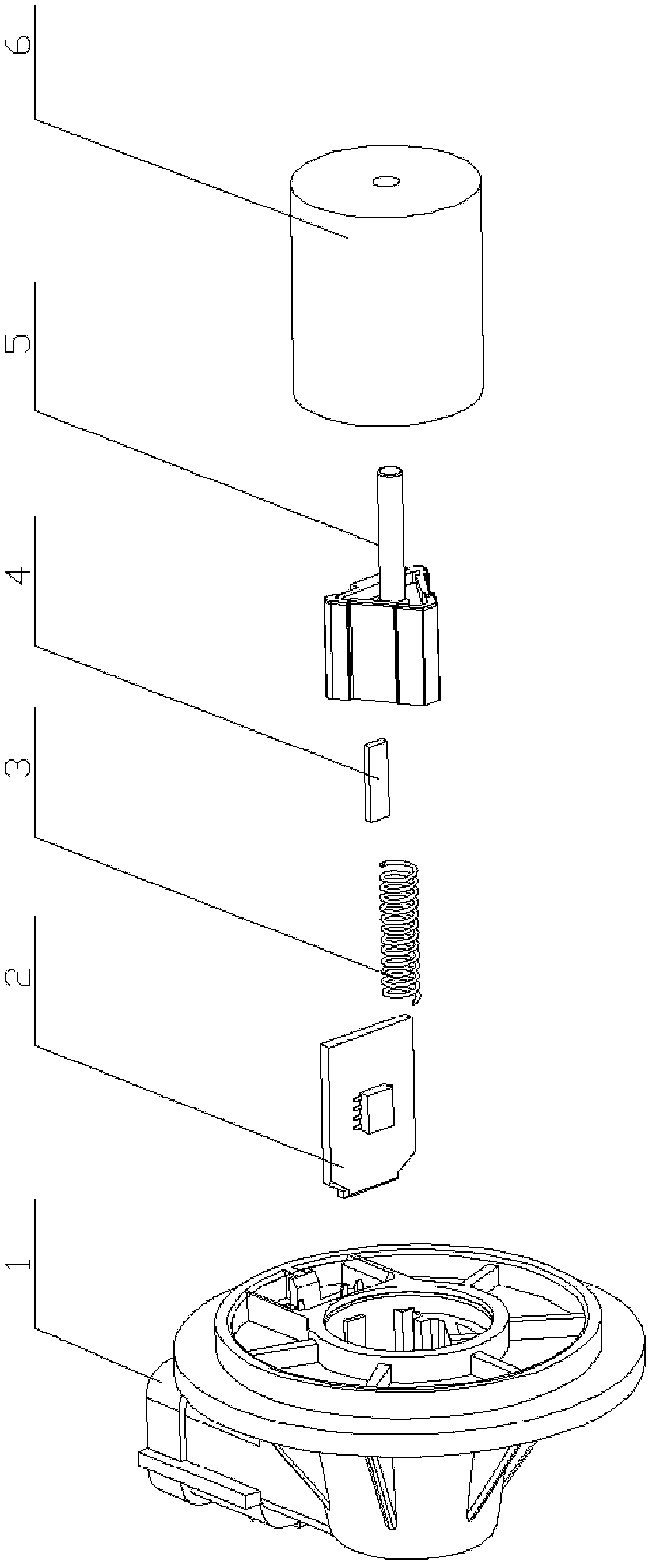

[0021] Such as figure 1 , 2 , 3, the present invention includes a cylindrical housing 1, a circuit board 2, a magnet 4, a sliding handle 5, a magnetic shield 6, a metal terminal pin 7 and a Hall chip 8, and the inner wall of the housing 1 is provided with There is a card slot, the circuit board 2 and the metal terminal pin 7 are installed in the card slot on the inner wall of the housing 1, the Hall chip 8 is installed on the side of the circuit board 2 facing the center of the housing 1, and the rear of the sliding handle 5 The end is slidingly installed in the housing 1, and the end of the sliding handle 5 is connected to the inner top surface of the housing 1 through the spring 3; the rear end side of the sliding handle 5 is provided with a card slot, and a magnet is installed in the card slot 4. There is also a ring groove on the side wall of the housing 1, and the ring groove matches the shape of the magnetic shield 6. The magnetic shield 6 is installed in the ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com