Zero correction method and device of torque sensor

A technology of torque sensor and zero point correction, which is applied in measuring devices, calibration/testing of force/torque/power measuring instruments, instruments, etc., can solve active steering or direction killing, torque sensor potentiometer slider and control screw Ball groove mechanical wear, loss and other problems, to achieve the effect of accurate and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

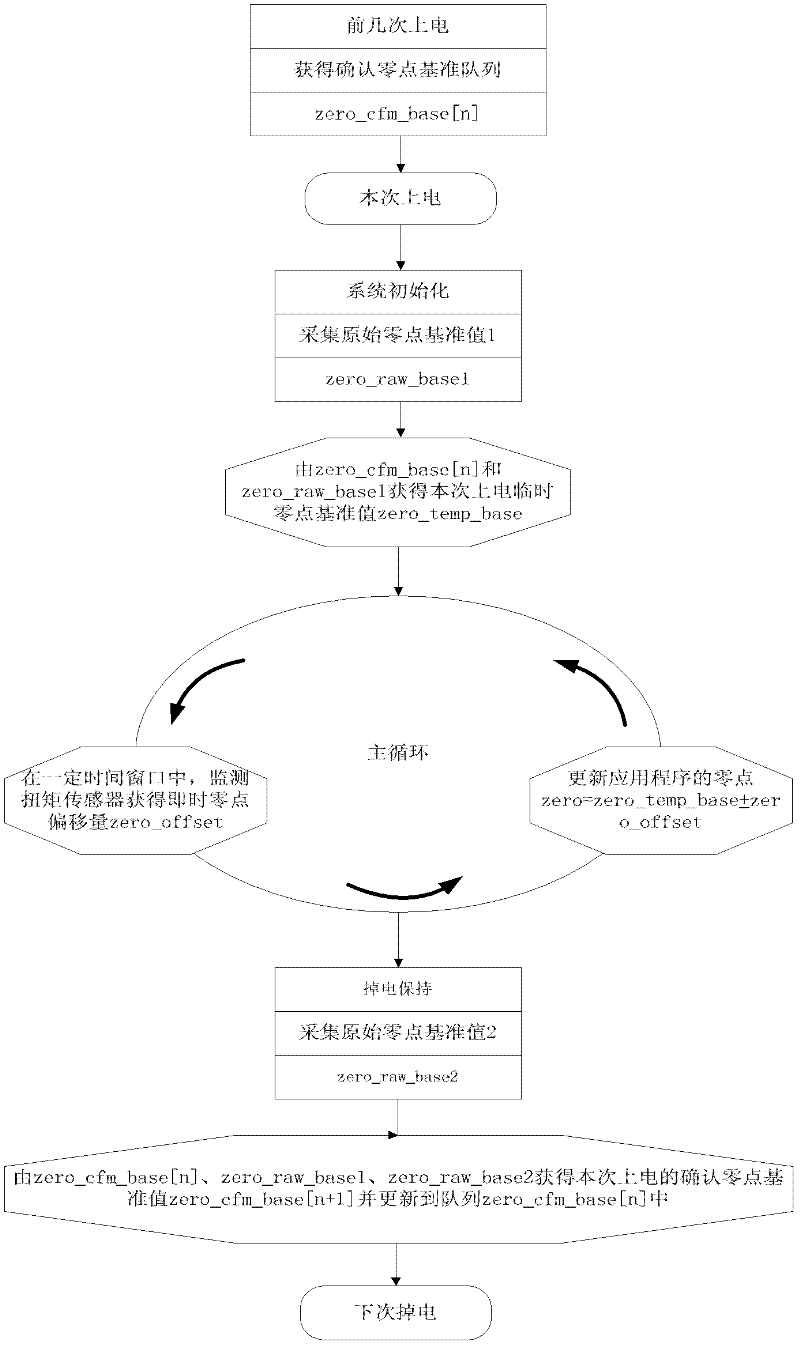

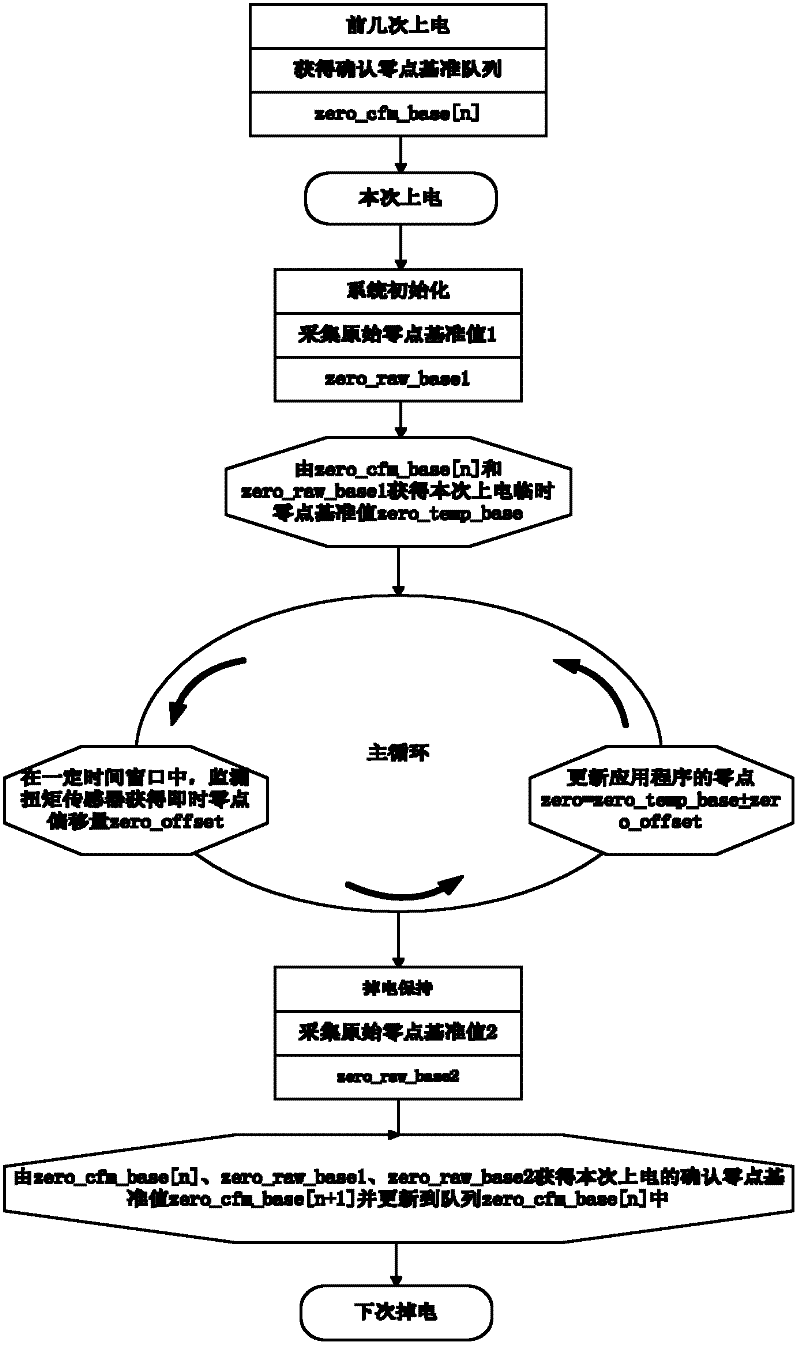

[0089] A zero point correction device of a torque sensor according to the present invention comprises:

[0090] Module A is used to read the zero point reference value confirmed and saved after the previous power-on work of the torque sensor respectively to obtain the zero point reference value queue;

[0091] Module B is used to collect the original zero reference value of the torque sensor when it is powered on this time;

[0092]Module C, for comparing the original zero reference value of module B with each zero reference value in module A;

[0093] If the compared differences are all within the set range, the original zero reference value of module B will be used as the temporary zero reference value obtained after static zero point learning; otherwise, the torque sensor in module A will be confirmed and saved after the last power-on work The zero-point reference value is used as the temporary zero-point reference value;

[0094] Module D, for sampling the torque sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com