Method for detecting dispersibility of titanium white in plastics

A detection method, titanium dioxide technology, applied in the chemical industry, can solve the problems of many equipments, difficult detection, long detection process, etc., and achieve the effect of high detection accuracy, strong operability and short detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

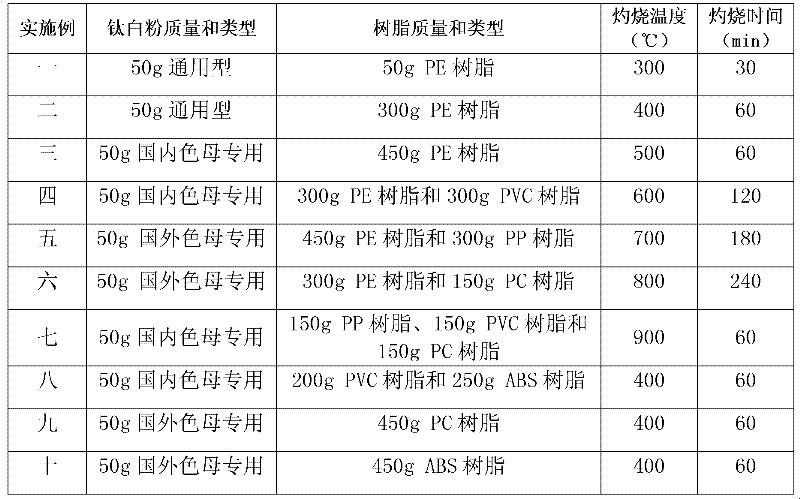

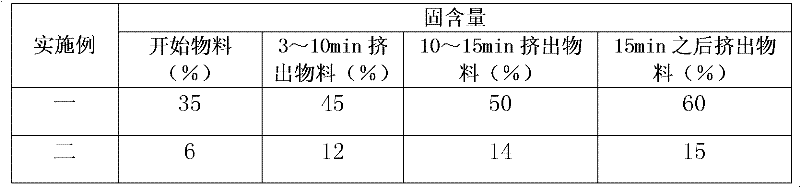

[0026] Embodiment 1: Take commercially available 50g general-purpose titanium dioxide and 50g PE resin, after fully mixing, place in twin-screw extruder feeding device and carry out twin-screw extruding, take and start to extrude respectively in the extruding process 1 g each of the material, the material whose extrusion time is between 3 and 10 minutes, the material whose extrusion time is between 10 and 15 minutes, and the material after 15 minutes of extrusion, is placed in a muffle furnace and burned for 30 minutes at 300 ° C. The solid content of each extrusion period was measured respectively, and the measured data are shown in Table 2.

Embodiment 2

[0027] Embodiment two: take by weighing commercially available 50g general-purpose titanium dioxide and 300g PE resin, after fully mixing, place in twin-screw extruder feeding device and carry out twin-screw extrusion, take and start to extrude respectively in extrusion process 1 g each of the material, the material with an extrusion time of 3 to 10 minutes, the material with an extrusion time of 10 to 15 minutes, and the material after 15 minutes of extrusion, was placed in a muffle furnace and burned at 400 ° C for 60 minutes. The solid content of each extrusion period was measured respectively, and the measured data are shown in Table 2.

Embodiment 3

[0028] Embodiment 3: Take commercially available 50g of domestic color masterbatch special-purpose titanium dioxide and 450g of PE resin, after fully mixing, place in twin-screw extruder feeding device and carry out twin-screw extruding, take starting point respectively in extruding process 1g each of the extruded material, the material whose extrusion time is between 3 and 10 minutes, the material whose extrusion time is between 10 and 15 minutes, and the material after 15 minutes of extrusion, is placed in a muffle furnace and burned for 60 minutes at 500 ° C. . The solid content of each extrusion period was measured respectively, and the measured data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com