Method for detecting pipeline defects based on three-dimensional data points acquired through circle structured light vision detection

A circular structured light and three-dimensional data technology, which is applied in the direction of optical testing of defects/defects, can solve the problems of low defect detection accuracy, low test efficiency, complex scanning structure, etc., achieve accuracy and precision improvement, and simple and effective judgment methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Circular Structured Light Visual Inspection System Acquired from 3D Point Cloud Data

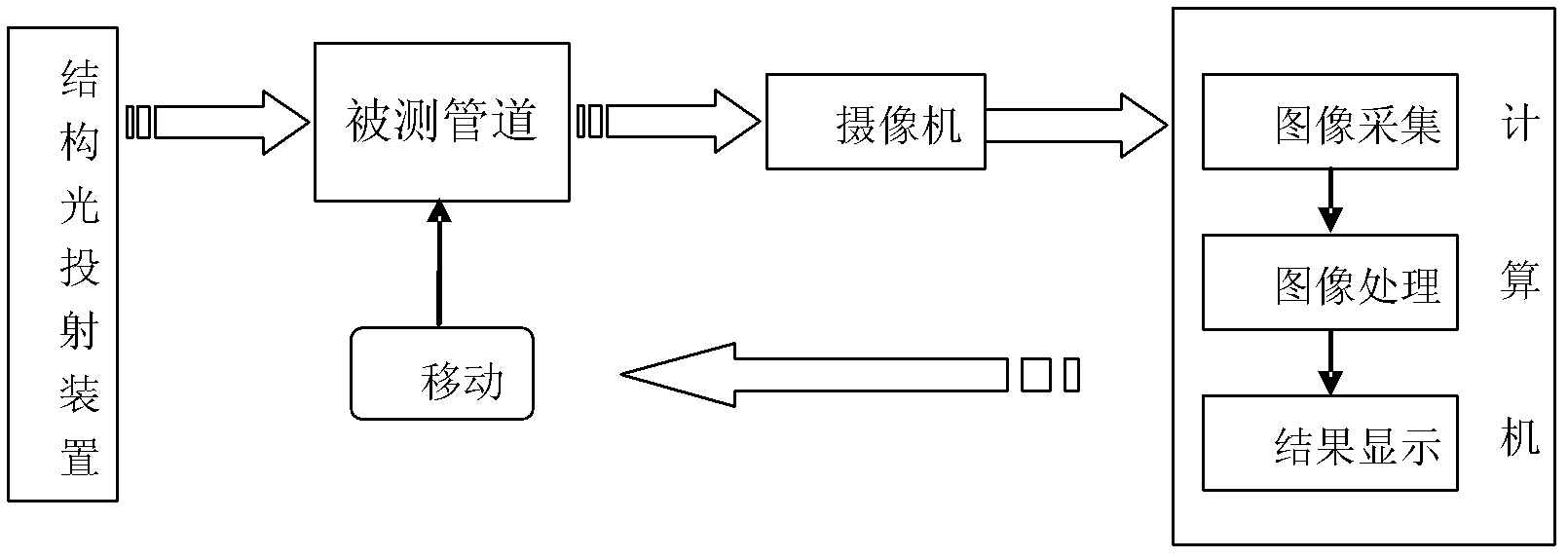

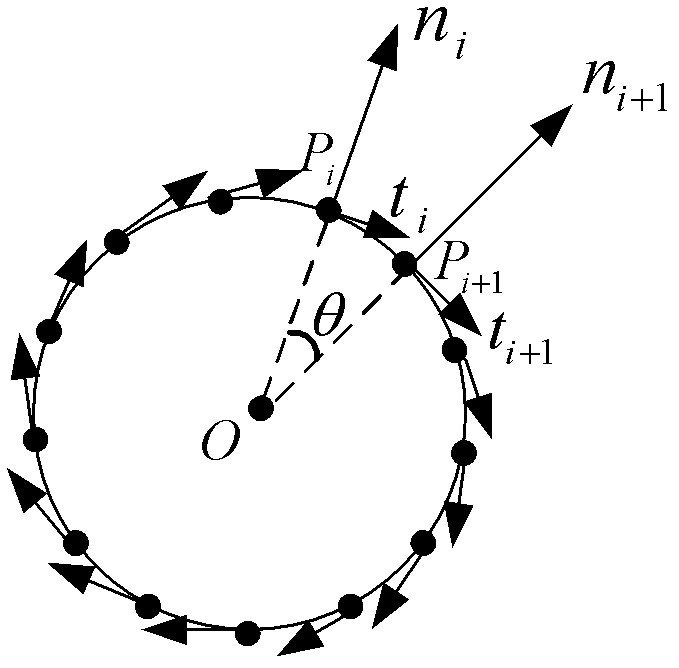

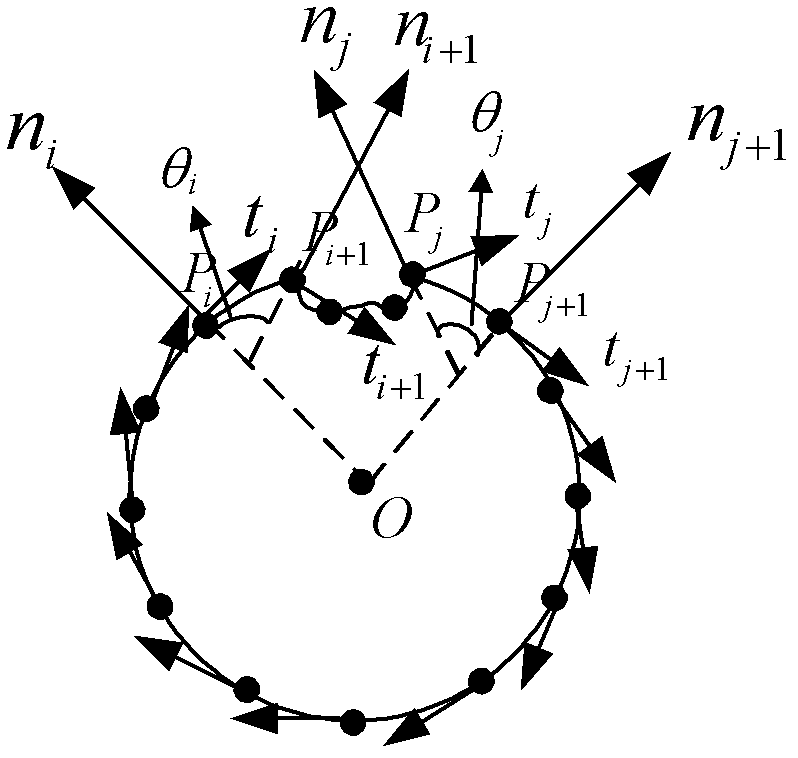

[0032] The structure of the circular structured light vision detection technology system is as follows: figure 1 Shown: the circular structured light projector projects structured light to the inner wall of the pipe, and the conical surface structured light intersects with the inner surface of the pipe to form a bright circular closed light strip. Modulating the shape information of the light strip changes the shape of the light strip, so the light strip reflects the three-dimensional shape of the inner wall of the pipeline. The camera located in the pipeline captures the light strip image on the inner surface, and transmits it to the computer through the image acquisition card. The computer extracts the sub-pixel feature of the center of the light strip from the acquired light strip image on the inner surface of the pipeline, and calculates the three-dimensional information of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com