Microfluidic chip for isoelectric focusing separation

A microfluidic chip and isoelectric focusing technology, which is applied in the direction of material analysis, material analysis, and DNA preparation through electromagnetic means, can solve the problems that the separation resolution needs to be further improved and the separation effect cannot be achieved, and achieve good results and Practical significance, reagent saving, simple production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

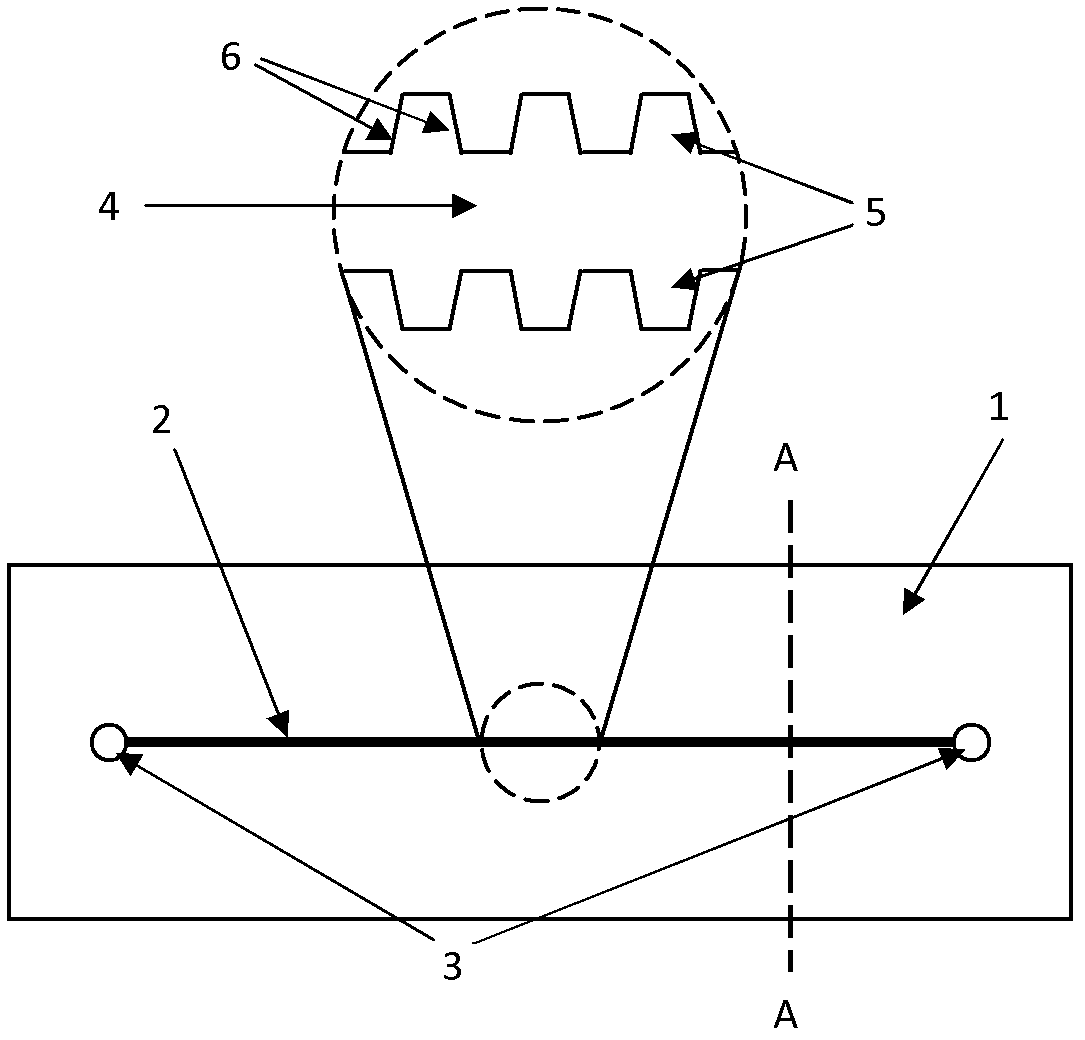

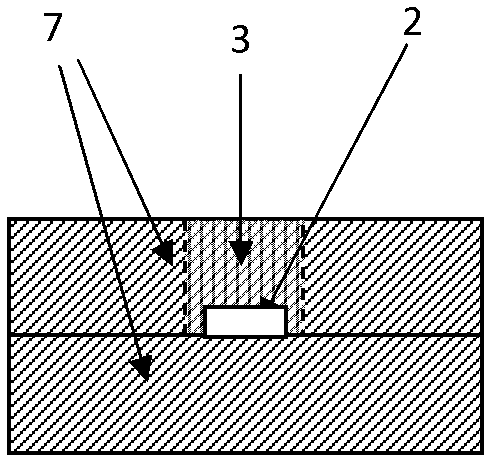

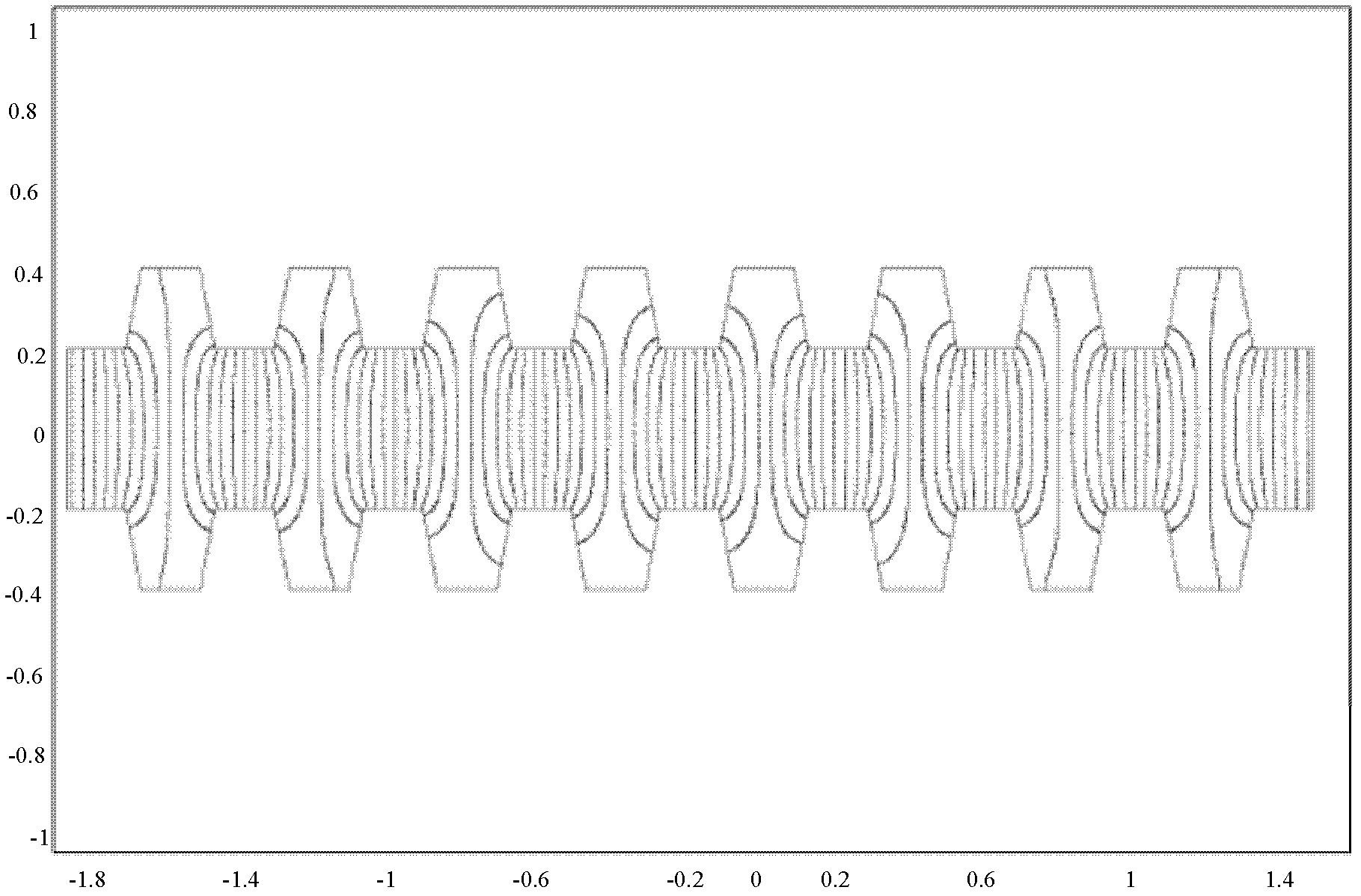

[0021] see figure 1 and 2 , the shrinkage region 4 and the expansion region 5 of the microchannel both have a length of 40 μm and a width of 50 μm and 100 μm respectively, and the ratio is 2. The connecting region 6 between the constricted region 4 and the enlarged region 5 has a length of 10 μm. The length of the repeating structure composed of the three parts of channel constriction region 4, expansion region 5 and connection region 6 can be 100 μm. Channels of different widths have different resistivities in the electric field and have different voltage drops, enabling nonlinear pH gradients during isoelectric focusing. The IPG strips used in conventional isoelectric focusing have several specifications, and the lengths are 7cm, 11cm, 17cm, 18cm and 24cm. If microchannels with the same length as IPG strips are made, 700, 1100, 1700, 1800 and 2400 repeating structures can be processed respectively. If each repeat structure accommodates one sample, peak capacities of 700,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com