Method for detecting zero-sequence voltage circuit of transformer substation

A zero-sequence voltage circuit and inspection method technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of non-generating zero-sequence voltage, incorrect zero-sequence voltage, power grid relay protection malfunction accidents, etc. Achieve the effect of simplicity, convenience, high reliability and less workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

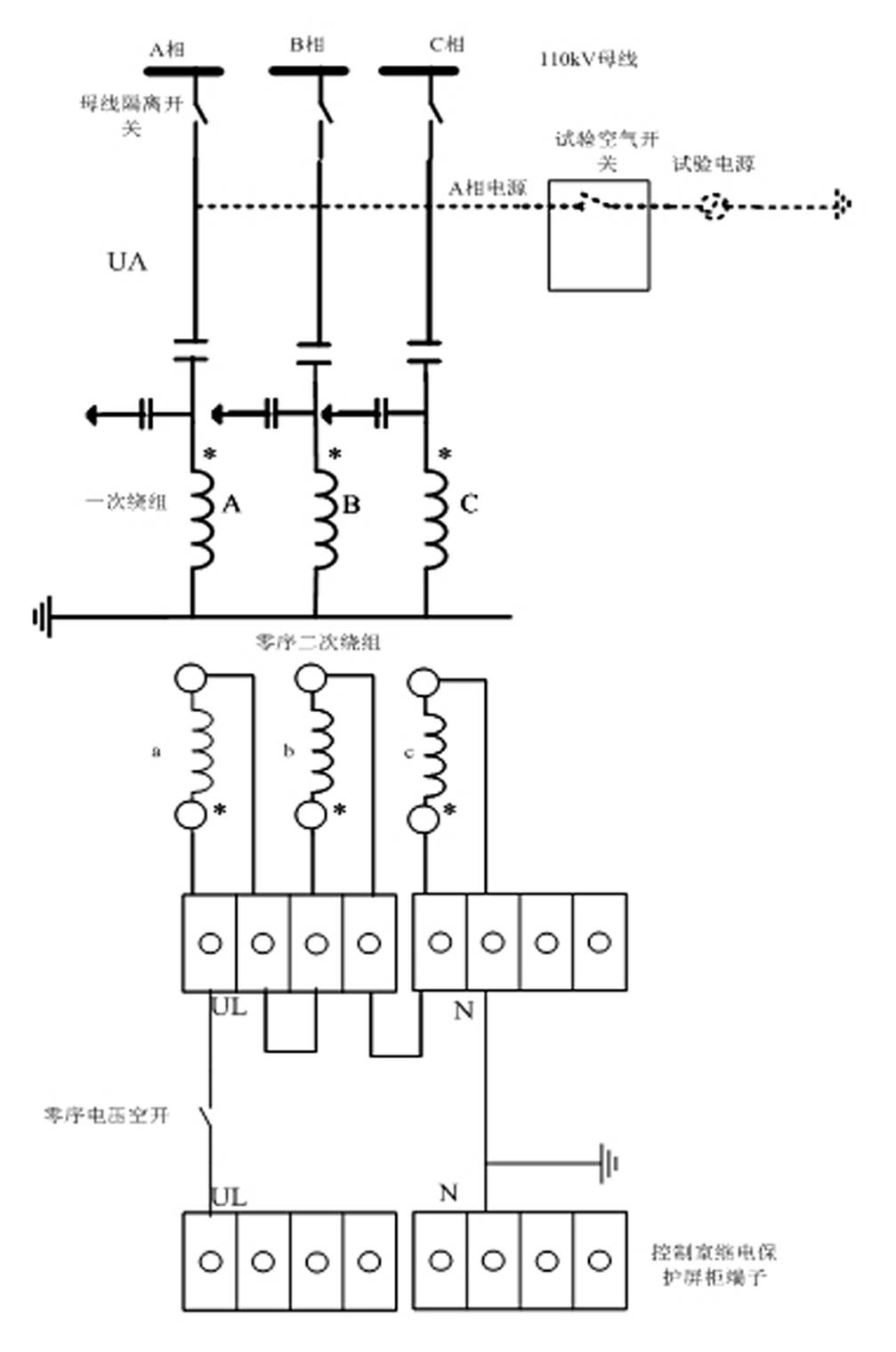

[0025] Substation zero-sequence voltage loop inspection method, the present invention is characterized in that, before the substation is put into production with live electricity, it is operated according to the following steps:

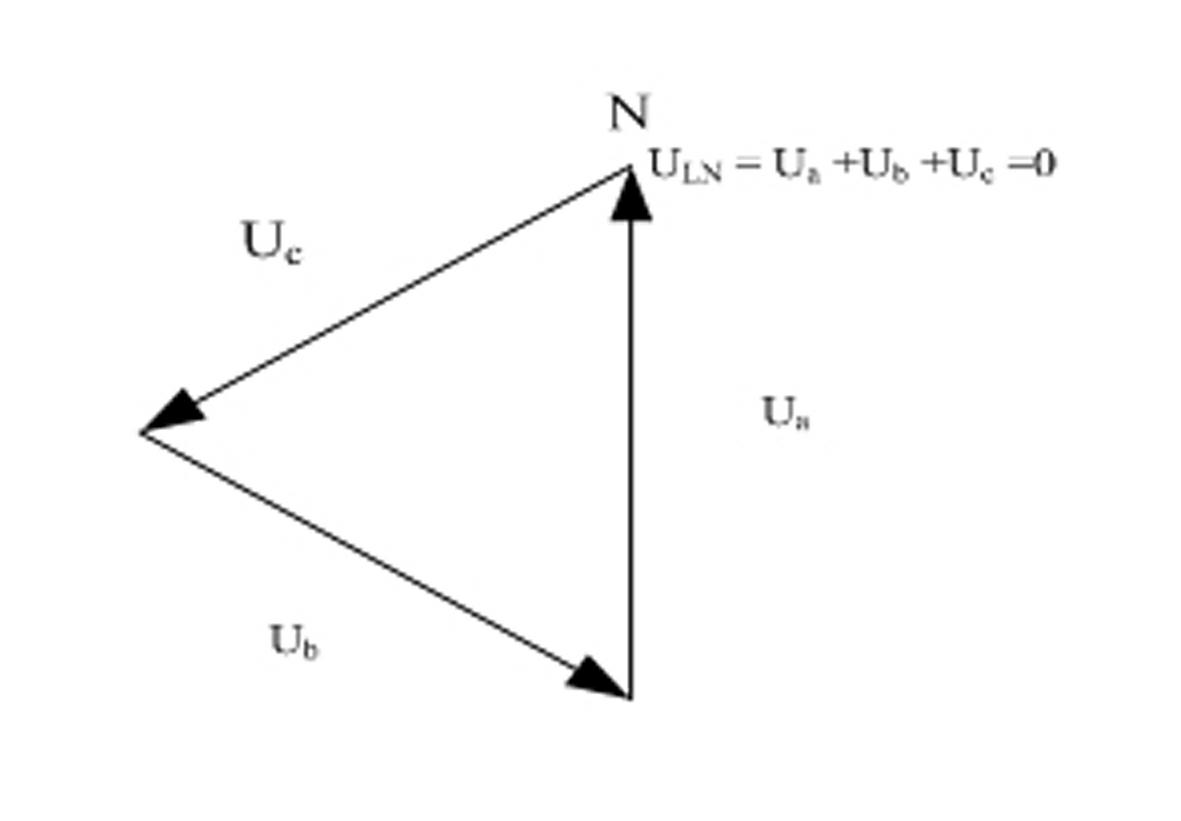

[0026] The first step is to add a single-phase 220V test voltage to the voltage transformer once, and use a high-precision multimeter to detect the zero-sequence voltage amplitude of the zero-sequence voltage outlet L terminal of the terminal box and the ground wire N terminal to be U LN1 , the voltage amplitude between the zero-sequence outgoing line L terminal and the applied test voltage A is U LA , the voltage amplitude between the test voltage A and the ground wire N is U AN ; Close the zero-sequence voltage air switch, and detect the voltage amplitude of L and N at the control room screen cabinet terminal as U LN1 ';

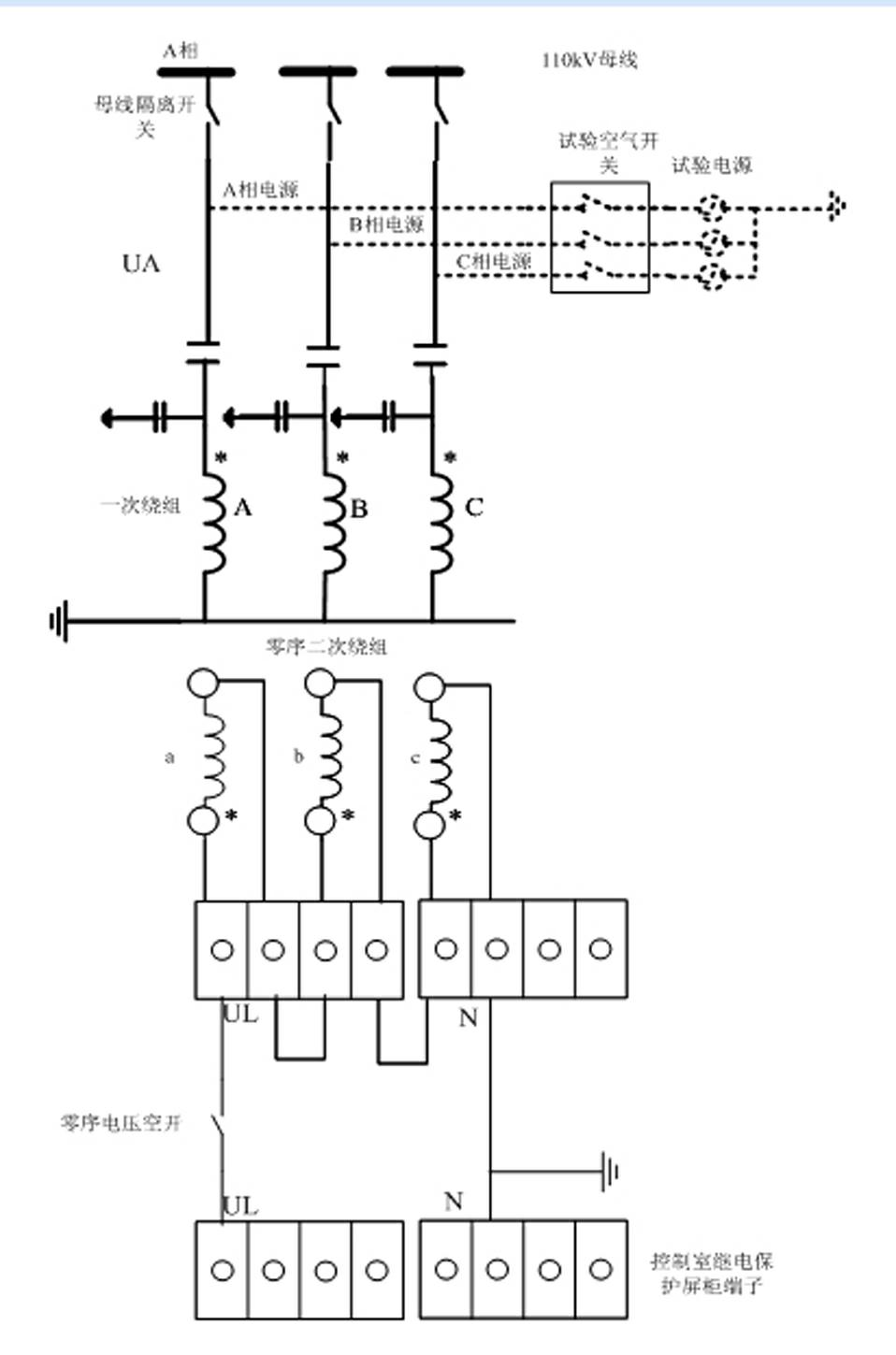

[0027] The second step is to add the three-phase symmetrical positive phase sequence 380V line voltage at a time, and detect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com