Method for detecting offset of focus of lithography machine

A technology of lithography machine and focal length, which is applied in the direction of testing optical performance, microlithography exposure equipment, and photolithography exposure equipment, etc. It can solve the problems of high measurement position requirements, production loss, and final result interference, so as to avoid judgment effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

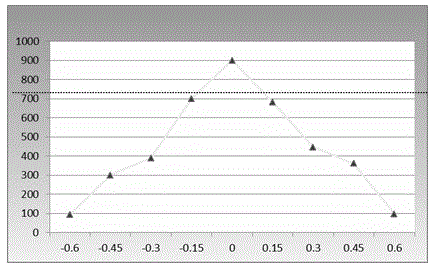

[0019] figure 1 It is a schematic structural diagram of a reference figure in the method for detecting focal length offset of a lithography machine according to the present invention; figure 2 It is a schematic structural diagram of a test pattern in the method for detecting focal length offset of a lithography machine according to the present invention; image 3 It is a graph of the relationship between the similarity score and the focal length of the lithography machine in the method for detecting the focal length offset of the lithography machine in the present invention; Figure 4 It is a schematic diagram of the pattern on the wafer after exposure and its similarity score in the actual process of the method for detecting the focal length offset of the lithography machine of the present invention.

[0020] Such as Figure 1-4 As shown, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com