Structure of curved capacitive touch control panel

A capacitive touch, surface-shaped technology, applied in the direction of electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of weak stress intensity, substrate fracture, waste, etc., and reduce the difficulty of processing , the shape is easy to control, and the effect of product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

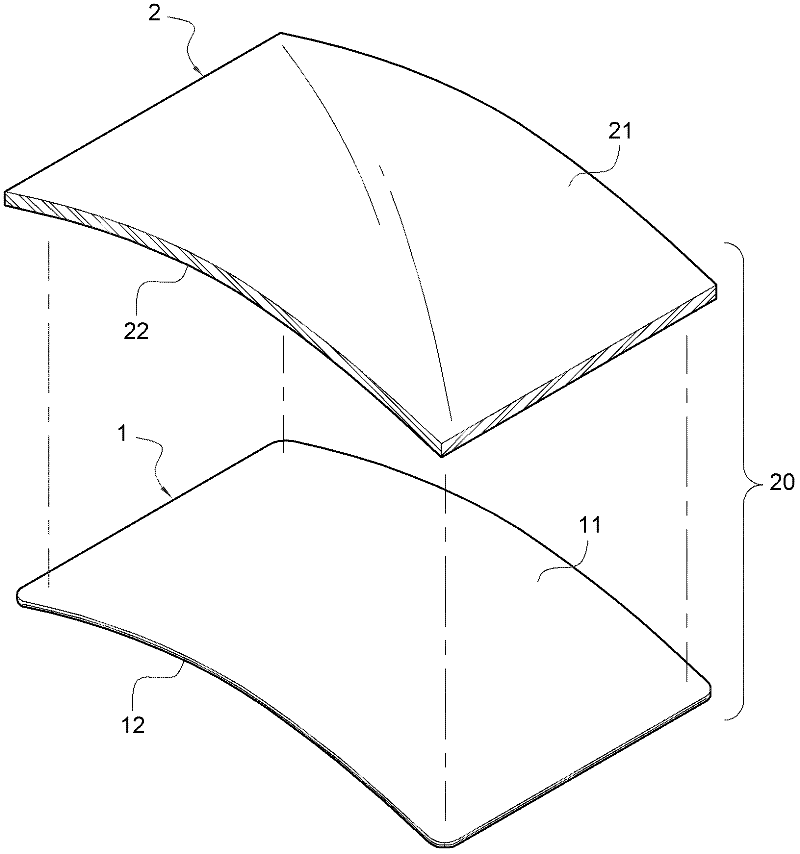

[0047] See figure 1 , Reveals a three-dimensional exploded view of an embodiment of the present invention, and cooperates with Figure 2A to Figure 8 The method for manufacturing the curved capacitive touch panel of the present invention includes the following steps:

[0048] (1) Provide a flat flexible circuit board 10 with capacitive touch function (such as Figure 2A Shown).

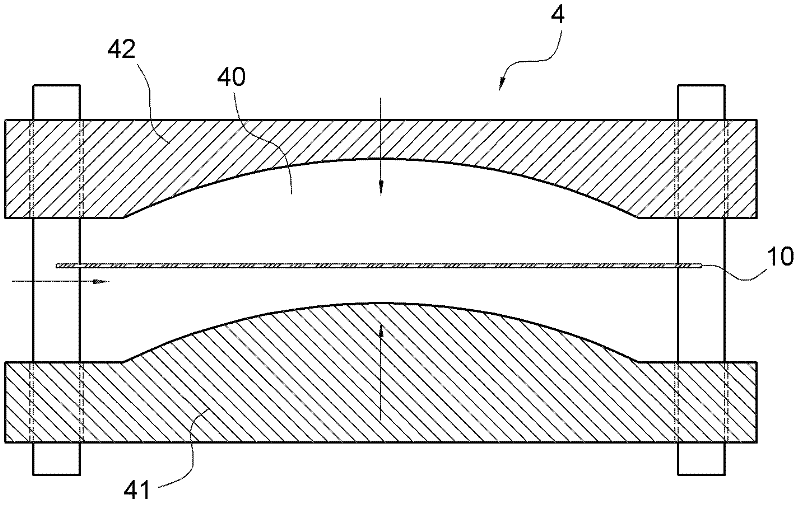

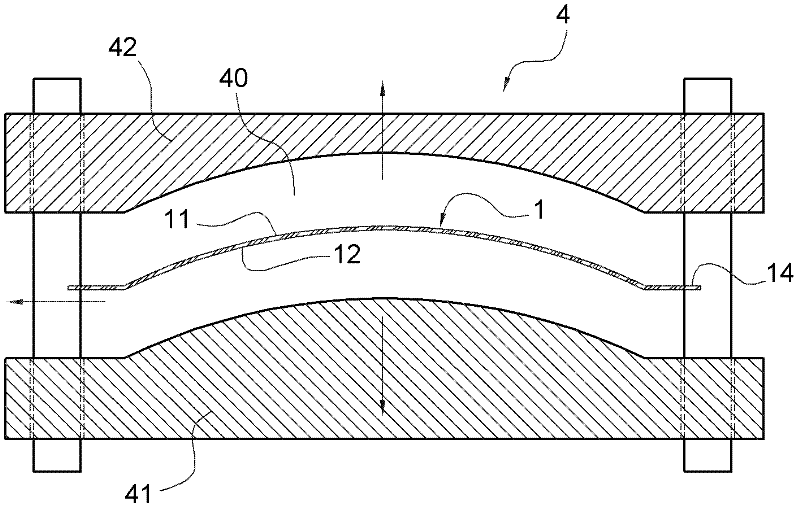

[0049] (2) The flat flexible circuit board 10 is formed in a curved surface using a molding method. The molding method may be hot pressing in this embodiment, and mainly is to deliver the flat flexible circuit board 10 to a hot pressing In the cavity 40 between a male mold 41 and a female mold 42 of the molding device 4 (such as Figure 2A (Shown), the male mold 41 and the female mold 42 are preheated to a preset temperature (approximately 200 to 250 degrees Celsius), and the preset temperature can be used to thermoplastic the flat flexible circuit board 10 Molding temperature; in this way, the flat flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com