Single-body transformer having novel wiring structure

A wiring structure and transformer technology, applied in the field of transformers, can solve the problems of high induced voltage, potential safety hazards, low utilization rate of voltage regulating coil materials, etc., and achieve the effect of reducing induced voltage, avoiding circulating current, reactance and resistance drop completely consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

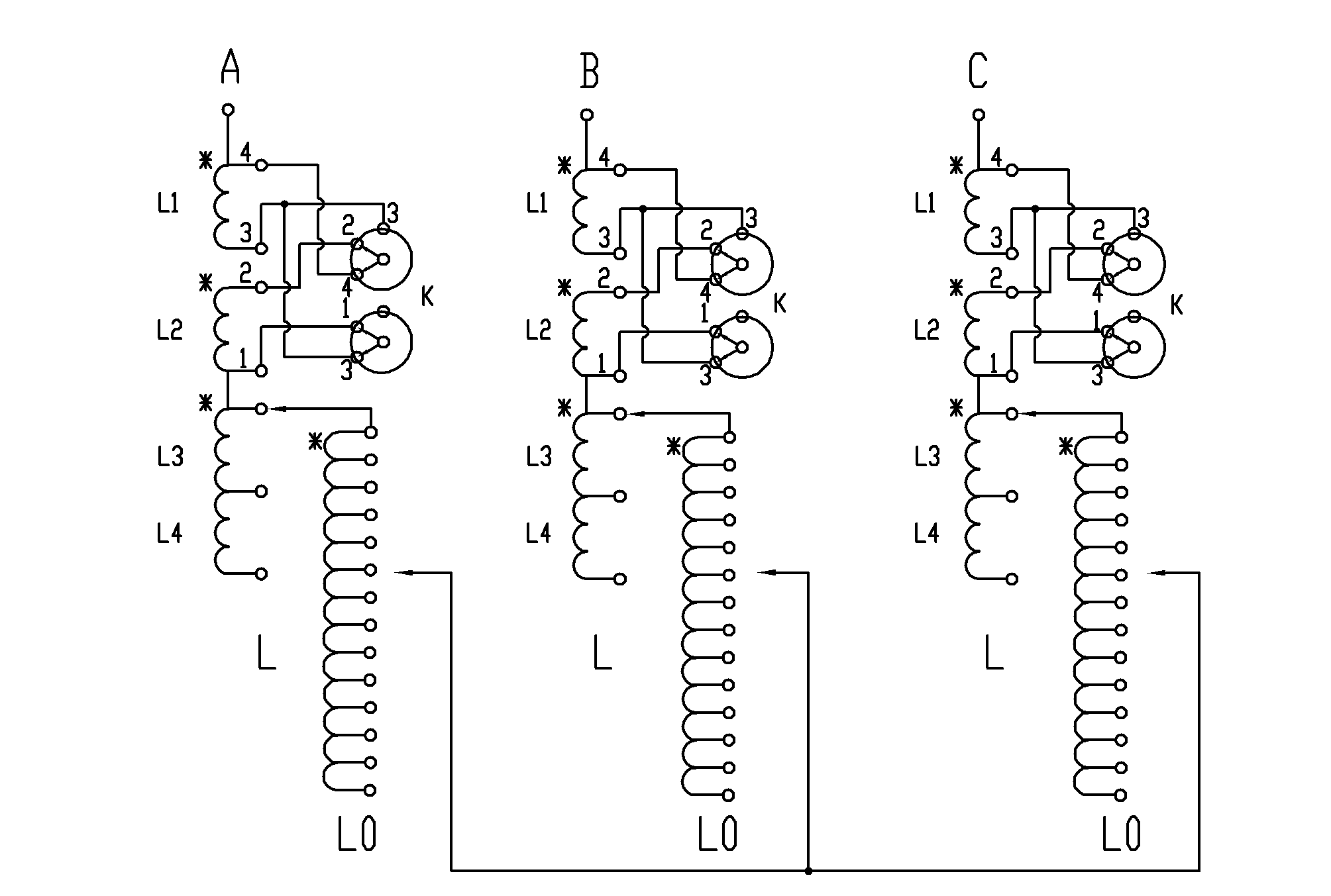

[0031] A single-body transformer with a new wiring structure, the voltage regulation coil of each phase has the same structure, including a coarse adjustment coil L and a fine adjustment coil L0, and the coarse adjustment coil L in each phase includes 4 gears connected in series or in parallel The coarse adjustment coils L1, L2, L3 and L4, the two gears at the front end of the 4-speed coarse adjustment coil are connected in series with the coarse adjustment coils at the rear end after being connected with the series-parallel switch K, that is: the third gear coarse adjustment coil Coil L3 is connected in series with the coarse adjustment coil L4 of the fourth gear, and the coarse adjustment coil L1 of the first gear and the coarse adjustment coil L2 of the second gear are connected in series with the coarse adjustment coil L3 of the third gear after being connected with the series-parallel switch K (see attached figure 1 ).

[0032] The number of turns of the first gear ...

Embodiment 2

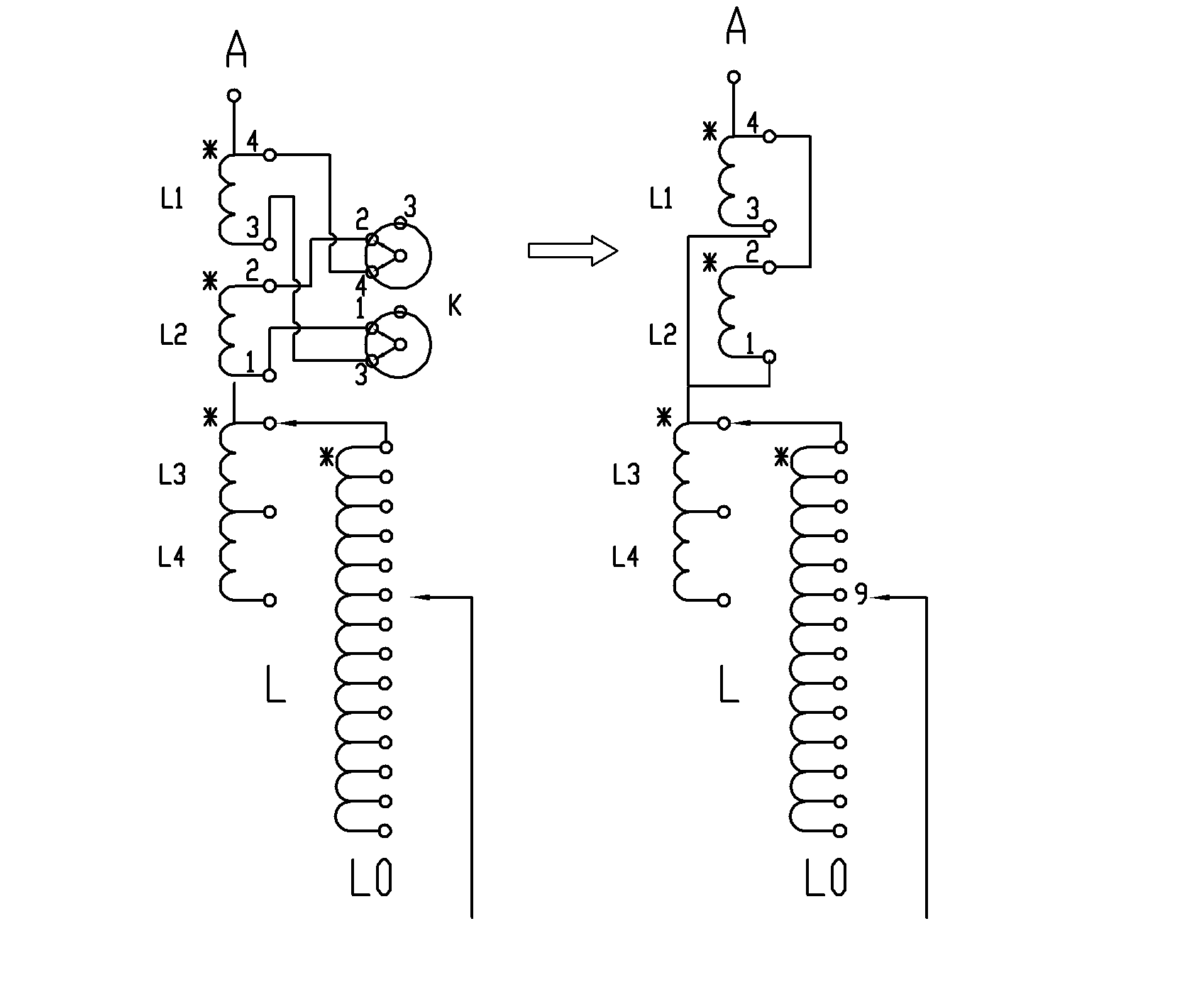

[0035] A single-body transformer with a new wiring structure, the voltage regulation coil of each phase has the same structure, including a coarse adjustment coil L and a fine adjustment coil L0, and the coarse adjustment coil L in each phase includes 4 gears connected in series or in parallel Coarse adjustment coils L1, L2, L3 and L4, the two gears located in the center of the 4-speed coarse adjustment coil are connected in series with the coarse adjustment coils at the front and rear ends of each gear after being connected with the series-parallel switch K, that is: the second The gear coarse adjustment coil L2 and the third gear coarse adjustment coil L3 are connected in series with the first gear coarse adjustment coil L1 and the fourth gear coarse adjustment coil L2 through the series-parallel switch K (see attached Figure 4 ).

[0036] The number of turns of the second gear coarse tuning coil L2 and the third gear coarse tuning coil L3 are equal, and the second gear...

Embodiment 3

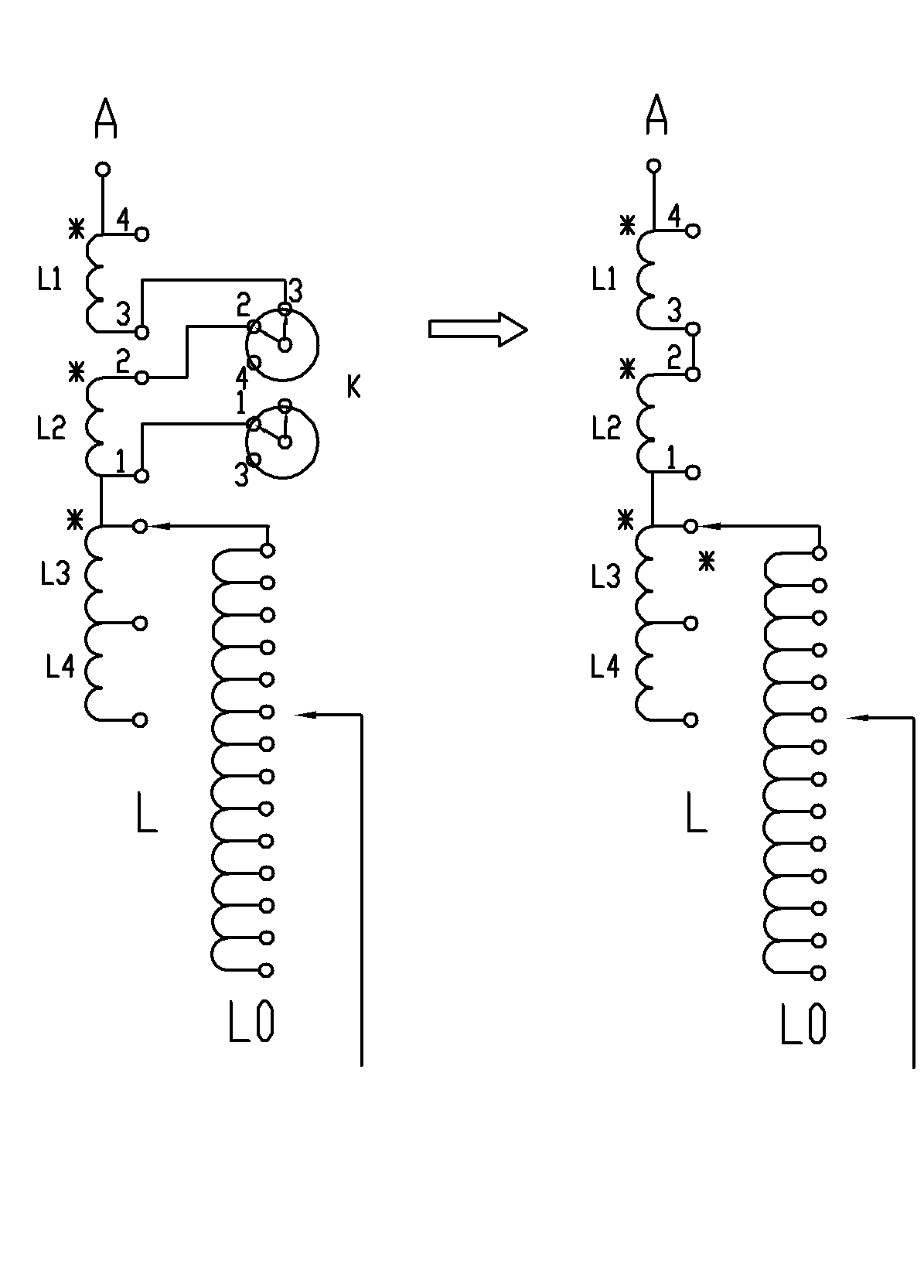

[0039] A single-body transformer with a new wiring structure, the voltage regulation coil of each phase has the same structure, including a coarse adjustment coil L and a fine adjustment coil L0, and the coarse adjustment coil L in each phase includes 4 gears connected in series or in parallel The coarse adjustment coils L1, L2, L3 and L4, the two gears at the rear end of the 4-speed coarse adjustment coil are connected in series with the coarse adjustment coils at the front end after being connected with the series-parallel switch K, that is: the first gear coarse adjustment coil Coil L1 is connected in series with the coarse adjustment coil L2 of the second gear, and the coarse adjustment coil L3 of the third gear and the coarse adjustment coil L4 of the fourth gear are connected in series with the coarse adjustment coil L2 of the second gear after being connected with the series-parallel switch K (see attached Figure 5 ).

[0040] The number of turns of the third gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com