Cylindrical high-capacity supercapacitor monomer structure

A technology of supercapacitor and single structure, applied in capacitor terminals, capacitor parts, capacitor shell/package, etc., can solve the problems of package rupture, user safety hazards, short life, etc., to avoid product explosion and ensure sealing effect , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and with reference to the accompanying drawings.

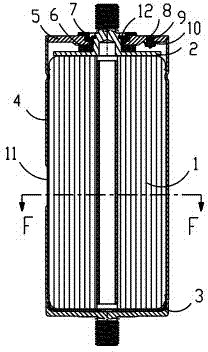

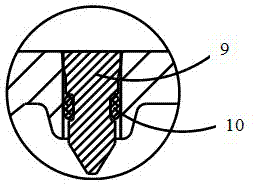

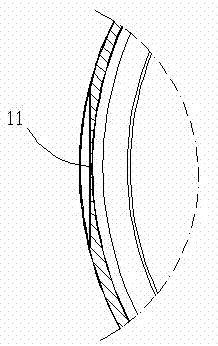

[0025] Such as figure 1 Shown is a schematic diagram of a cross-sectional structure of a supercapacitor in a preferred embodiment. This cylindrical high-capacity supercapacitor comprises shell 4, loam cake 5, upper current collector 2, winding core 1 and lower current collector 3, and the upper end surface and the lower end surface of described winding core 1 are blank aluminum foil, and described upper end surface and The lower end surfaces are respectively connected with the upper current collector 2 and the lower current collector 3 . The lower current collector 3 is arranged on the bottom of the casing 4 and connected thereto. The upper current collector 2 is placed in the upper cover 5 and connected thereto. In this preferred embodiment, the upper current collector 2 is inserted into the upper cover 5 and directly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com