Automobile lithium battery charge balancing method and balancing system

A charge balance and lithium battery technology, applied in the field of automobile lithium battery charge balance method and balance system, can solve the problems of poor battery balance, unadjustable discharge current, over-discharge, etc., to achieve good charge balance, good effect, accurate and flexible control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment discloses a charging balancing method for a lithium battery of an automobile, which is used to balance the difference between individual batteries when the lithium battery pack of the automobile is in a charging state, and the battery pack includes a plurality of single batteries connected in series;

[0053] During the charging process, two DC power supplies are loaded on each single battery for charging: one is an external DC power supply loaded at both ends of the battery pack, for example: a 42V / 10A DC power supply is directly connected to both ends of the battery pack ; The second is the compensation DC power supply loaded on both ends of each single battery, the current size of the compensation DC power supply can be adjusted according to requirements;

[0054] When starting to charge, all the DC compensation power supplies are turned on at full load, and output compensation current of the same size to compensate and charge each single battery. For ...

Embodiment 2

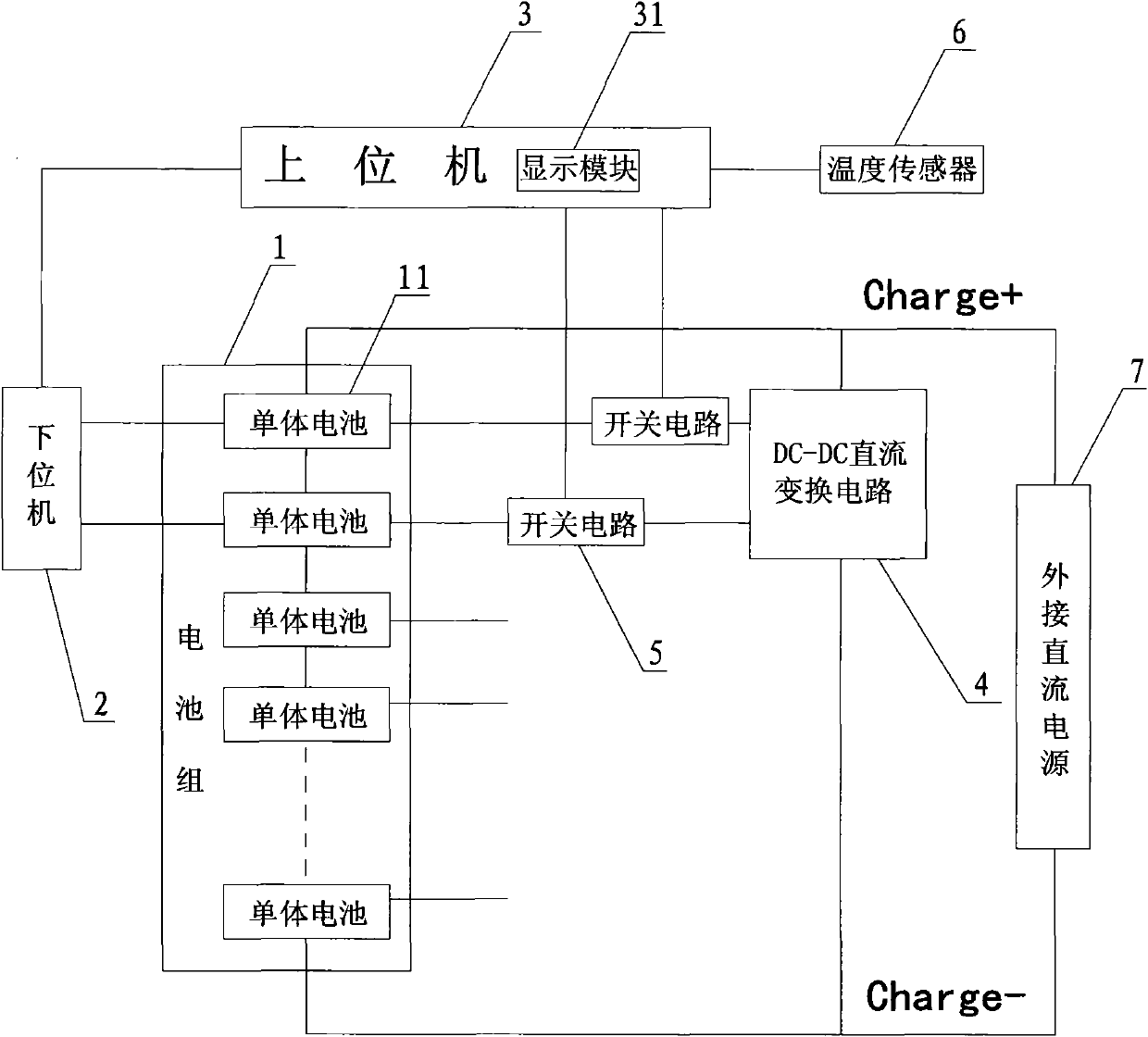

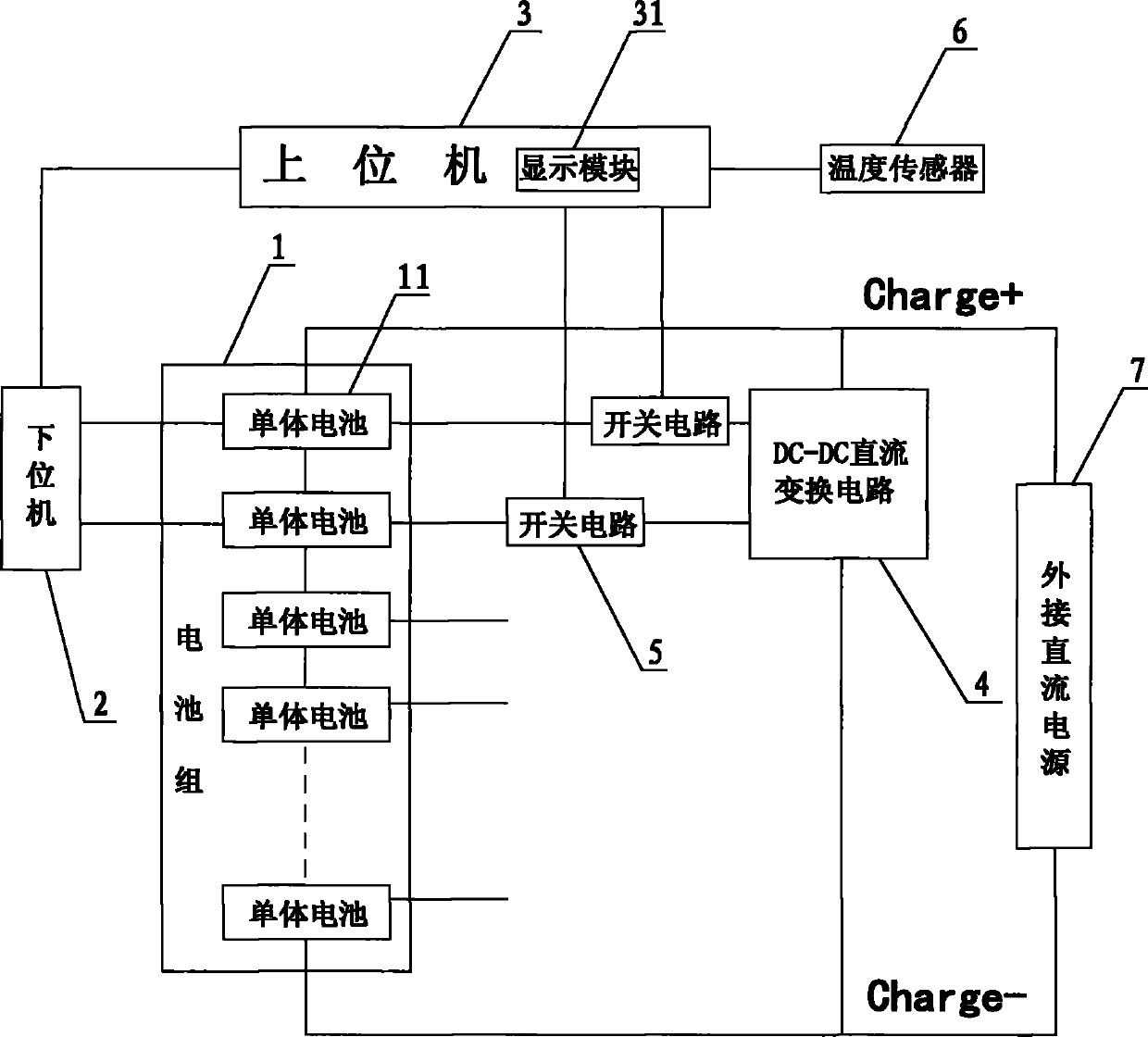

[0062] Such as figure 1 As shown, this embodiment discloses a charging balance system for a lithium battery for an automobile, which is used to balance the difference between individual cells when the lithium battery pack of an automobile is in a charging state. The battery pack 1 includes a plurality of single cells connected in series Body battery 11, and an external DC power supply 7 is charged at both ends of the battery pack 1; the balance system includes: lower computer 2, upper computer 3, switch circuit 5, and DC-DC conversion circuit 4, lower computer 2 Be PLC or single-chip microcomputer, host computer 3 is a main control module that includes CPU, and switch circuit can be field effect tube; The input terminal of described DC-DC direct current conversion circuit 4 is electrically connected with described external DC power supply 7, and its output terminal is connected with each monomer battery 11 through a described switch circuit 5, and each monomer battery 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com