Method for removing obstruction in micro-channel cooling equipment and self-repairing micro-channel cooling equipment

A technology of cooling equipment and microchannels, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as endangering system safety, achieve the effects of easy implementation, simple process, and eliminate the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

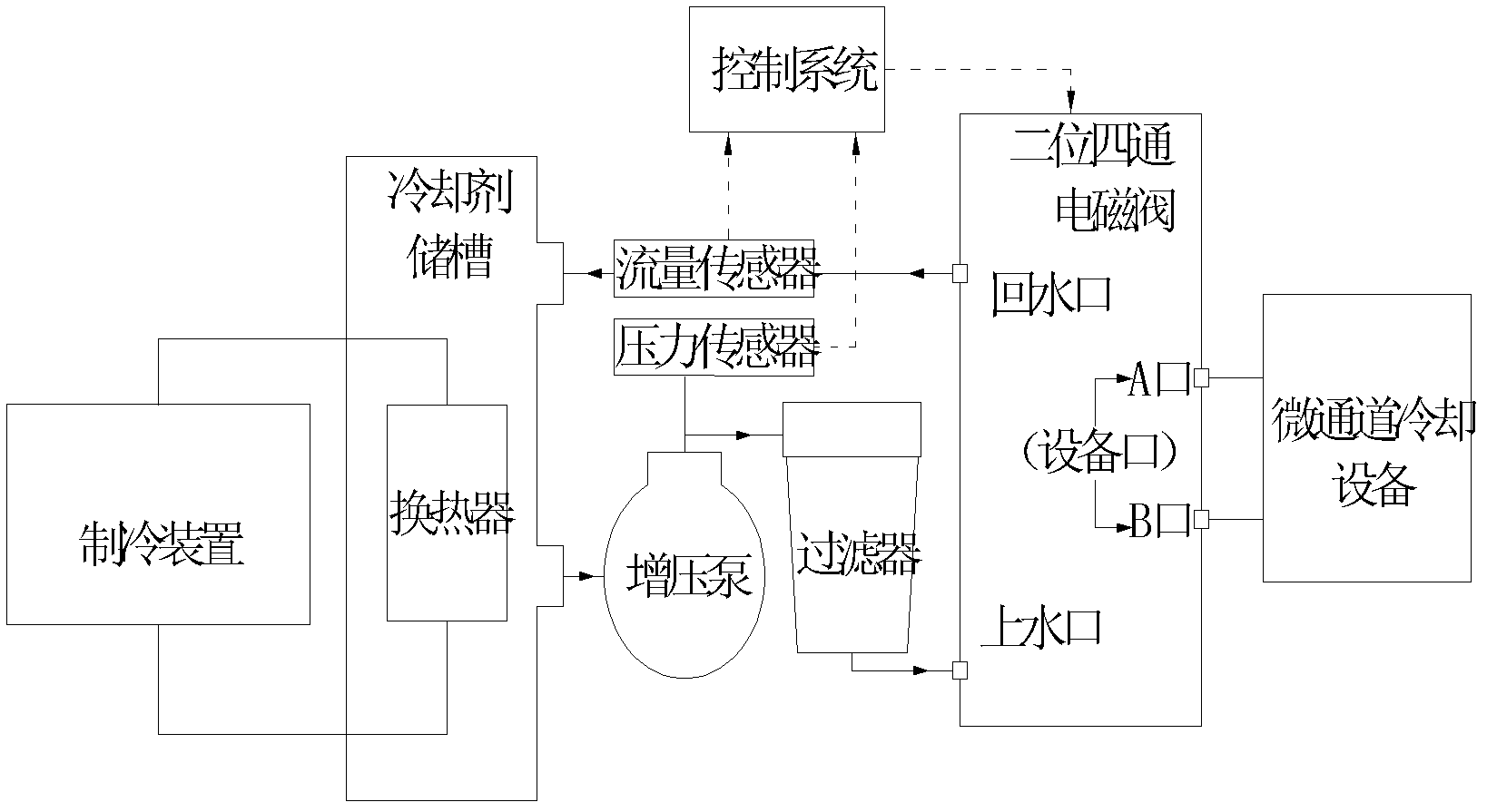

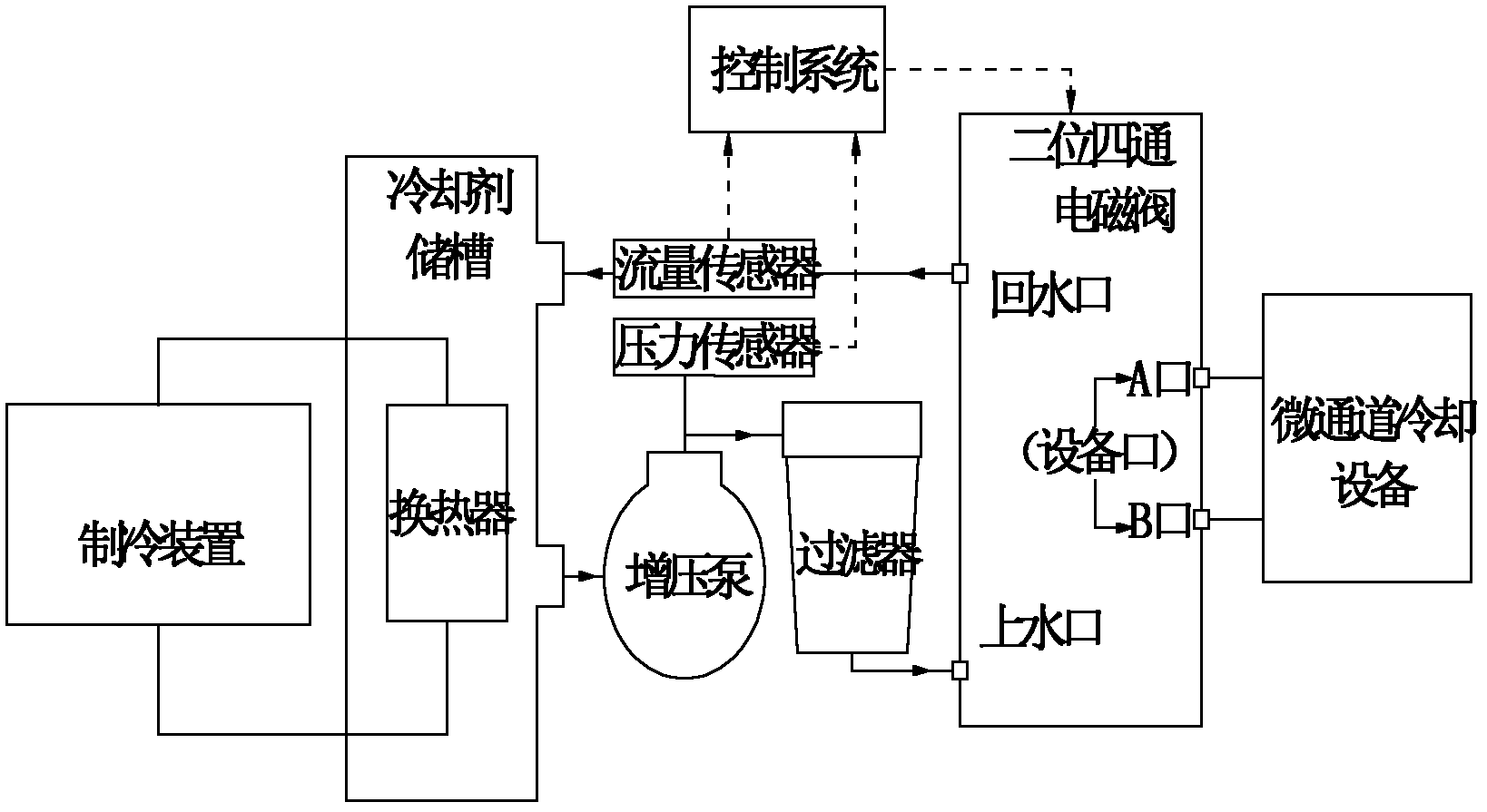

[0012] A method for removing blockages in a micro-channel cooling device and self-repairing, a cooling system for a micro-channel cooling device, as shown in the accompanying drawings, including a refrigeration system, a coolant storage tank, a booster pump, a filter, Micro-channel cooling equipment, pressure sensor, flow sensor, two-position four-way reversing solenoid valve and control device, the refrigeration system includes a refrigeration device and a heat exchanger and forms a closed system through pipelines, in which the heat exchanger is fixed in a closed coolant storage In the tank, the coolant storage tank, the booster pump and the filter are connected in series through pipelines to form the water supply pipeline for the coolant to enter the micro-channel cooling equipment, and the coolant flowing out of the micro-channel cooling equipment returns to the coolant storage tank through the pipeline to form a return circuit. The water pipeline is equipped with a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com