Magnetic levitation device with function of automatically lifting suspended matter

A technology for automatic lifting and suspension of objects, applied in the direction of magnetic attraction or thrust holding devices, electrical components, etc., can solve the problems of difficult display methods, affecting the suspension effect, and delaying time, so as to improve work stability and simple and compact structure , Guarantee the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

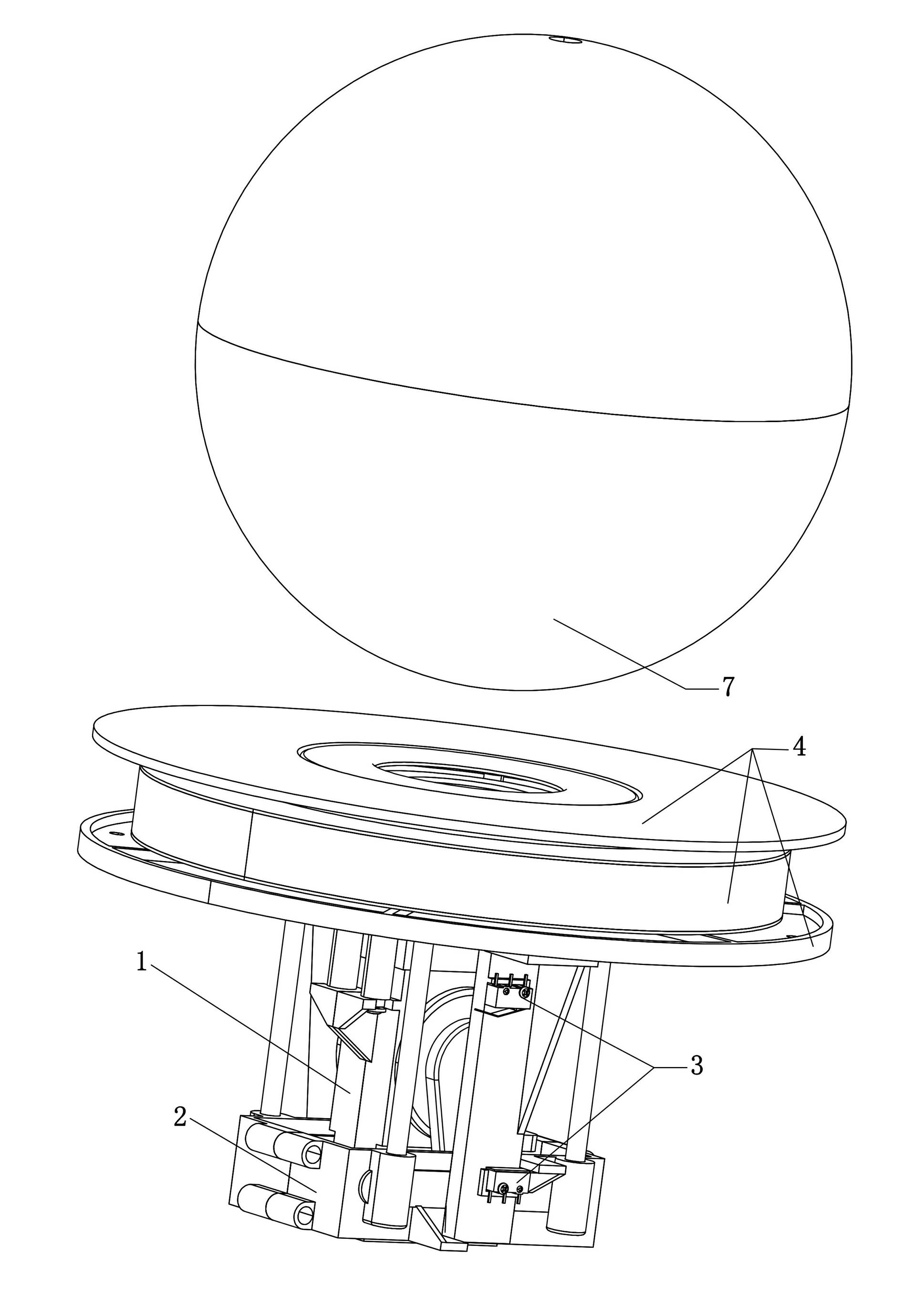

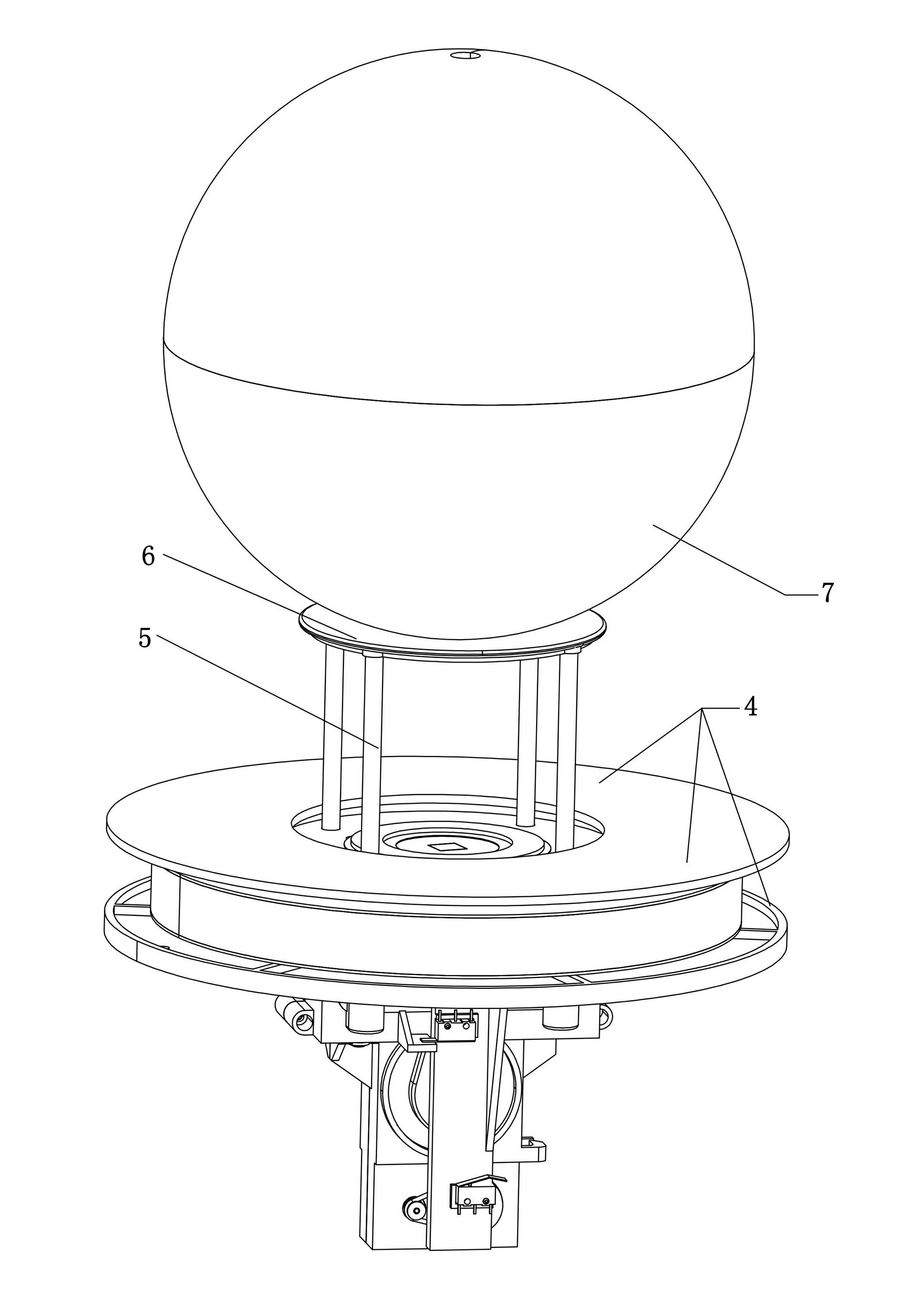

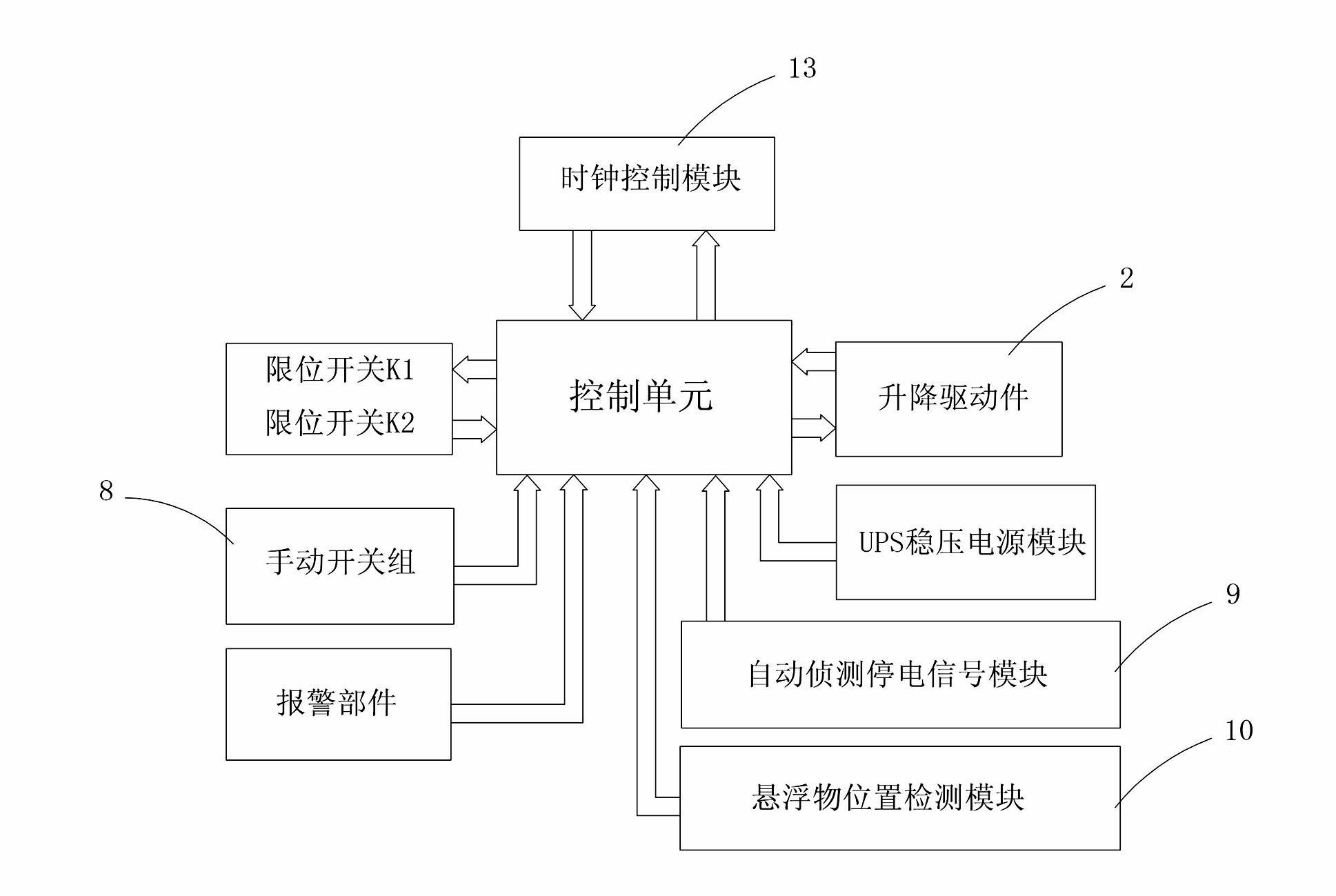

[0023] Such as figure 1 with figure 2 As shown, the magnetic levitation device with the function of automatic lifting of suspended objects of the present invention includes a magnetic levitation component 4, which is used to float the suspended object 7 on it by using the principle of magnetic levitation when the power is on. The magnetic levitation component 4 is provided with a lifting component at a position corresponding to the suspended object 7, that is, a through hole can be opened on the base of the magnetic levitation component 4, and the lifting component is arranged under the base and extends and penetrates through the through hole. Match with suspended solid 7 after the hole. The lifting assembly in the present invention includes a tray frame 6, a lifting column 5, a lifting transmission component and a control unit. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com