Greening coiled material

A coiled material and seed technology, which is applied in the field of new greening and environmental protection engineering materials, can solve problems such as the inability to directly use vegetation for restoration or greening, the inability to realize temperature control, water control functions, and unfavorable direct absorption by plant roots, so as to reduce maintenance costs, Achieve efficient utilization, increase germination rate and germination speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

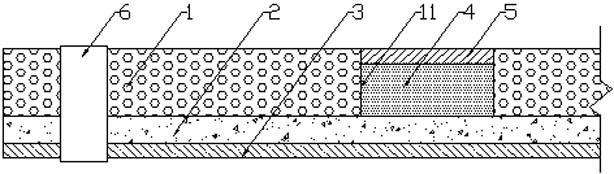

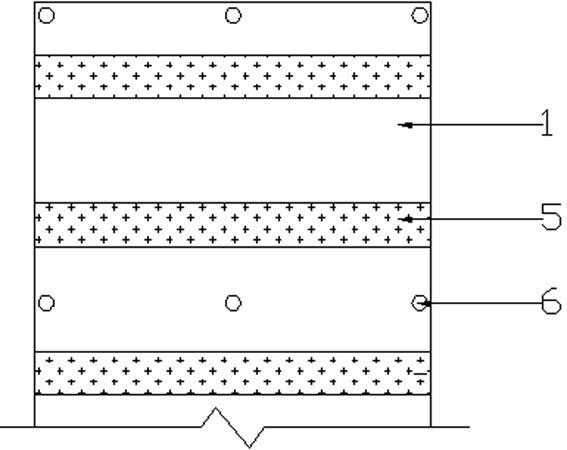

[0019] Embodiment 1: The greening coil material of the present invention comprises from top to bottom a water temperature and light control layer 1 provided with a filling tank 11, a root system planting layer 2, and a water / root regulating layer 3, and the seed mixture 4 is filled in the filling tank 11 , covering the seed germination band 5 on the seed mixture 4, the anchor ring 6 arranged in the greening roll material. Among them, the filling grooves 11 are distributed in a strip shape, water seepage holes 12 are opened on the upper and lower sides of the water temperature and light control layer 1, stretching folds 13 are arranged at intervals on the water / root regulating layer 3, and transverse holes 13 run through the seed germination belt 5. Notch 14 ( Figure 10 ). The ratio of components in the root system planting layer is 50 parts by weight of substrate, 0.5 parts of binder, 20 parts of water absorbing agent, 20 parts of fertilizer, 0.01 parts of disinfectant and 0...

Embodiment 2

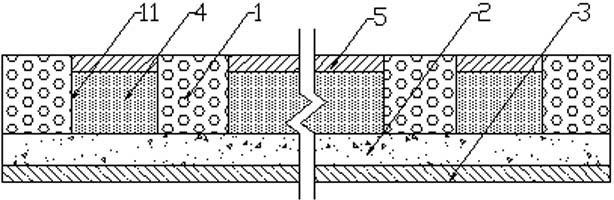

[0020] Embodiment 2: The greening coil material of the present invention comprises from top to bottom a water temperature and light control layer 2 provided with a filling tank 11, a root system planting layer 2, and a water / root regulating layer 3, and the seed mixture 4 is filled in the filling tank 11 , cover the seed germination band 5 on the seed mixture 4, and set the anchor ring 6 in the greening roll material. Wherein, the filling grooves 11 are distributed in a lattice shape, and the seed germination belt 5 runs through a longitudinal slit 15 ( Figure 11 ). The ratio of components in the root system planting layer is 80 parts by weight of substrate, 1 part of binder, 30 parts of water absorbing agent, 40 parts of fertilizer, 0.03 parts of disinfectant, and 0.005 parts of regulator; 20. Water retaining agent 8, binder 1, matrix 60, fertilizer 5, disinfectant 0.03 and regulator 0.005.

Embodiment 3

[0021] Embodiment 3: The greening coil material of the present invention comprises from top to bottom a water temperature and light control layer 1 provided with a filling groove 11, a root system planting layer 2, and a water / root regulating layer 3, and the seed mixture 4 is filled in the filling groove 11 , covering the seed germination belt 5 on the seed mixture 4, and being arranged on the flexible anchor belt 7 on both sides of the greening roll material laterally. Wherein, the filling grooves 11 are distributed in a lattice shape, and the seed germination belt 5 runs through a longitudinal slit 15 ( Figure 11 ). The compounding proportion of each component of its root system colonization layer is substrate 65, binder 0.7, water absorbing agent 25, fertilizer 30, disinfectant 0.02, regulator is 0.003; its compounding proportion of seed mixture is plant seed 15, water retention Agent 5, binder 0.7, matrix 50, fertilizer 4, disinfectant 0.02 and regulator 0.003.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com