Continuous crystallization method of tetraacetylethylenediamine

A tetraacetylethylenediamine and crystallization technology, applied in the crystallization field of tetraacetylethylenediamine, can solve the problems of uneven product particles, low production efficiency, different sizes, etc., and achieve production efficiency and product quality and particle size control. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

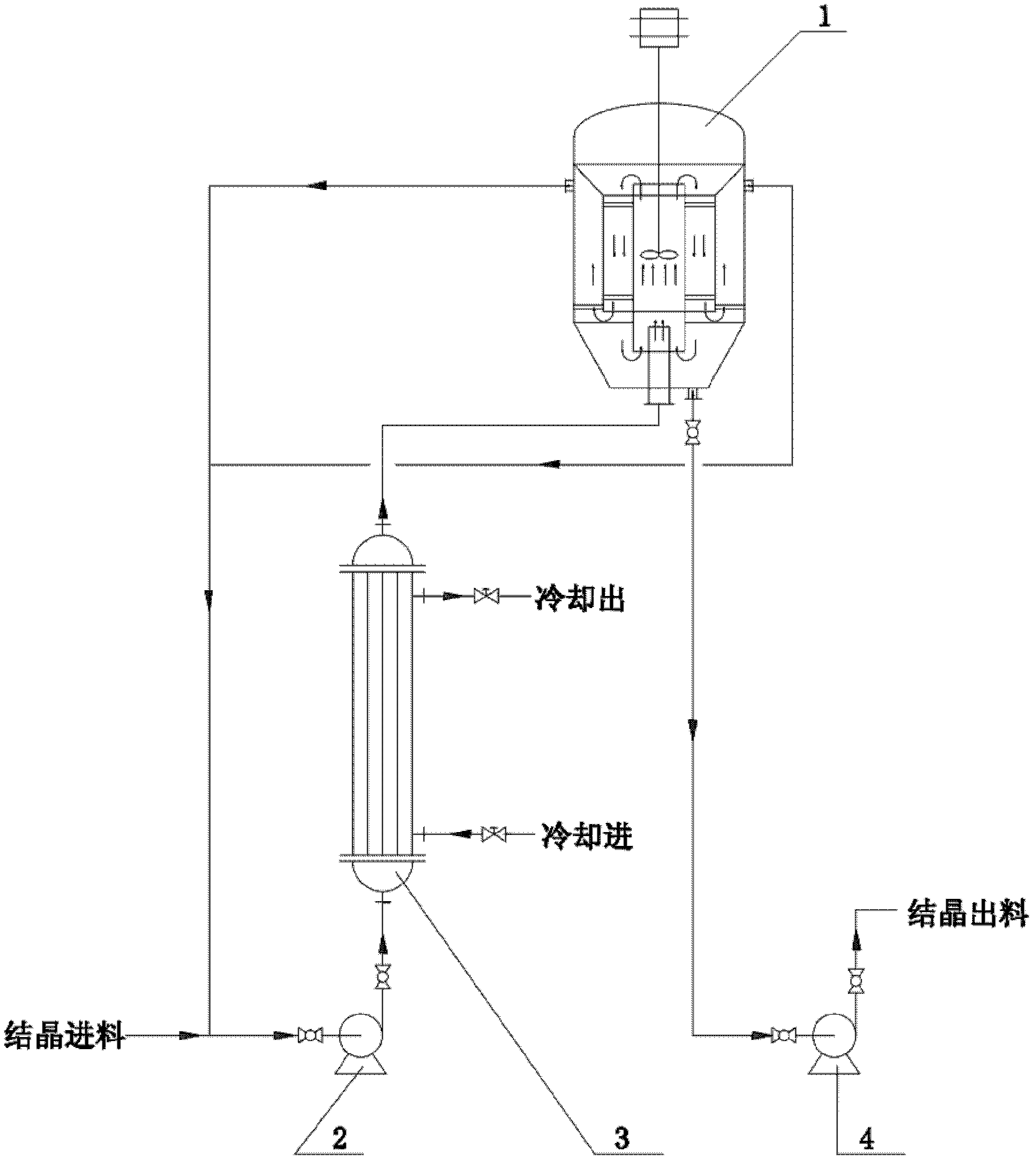

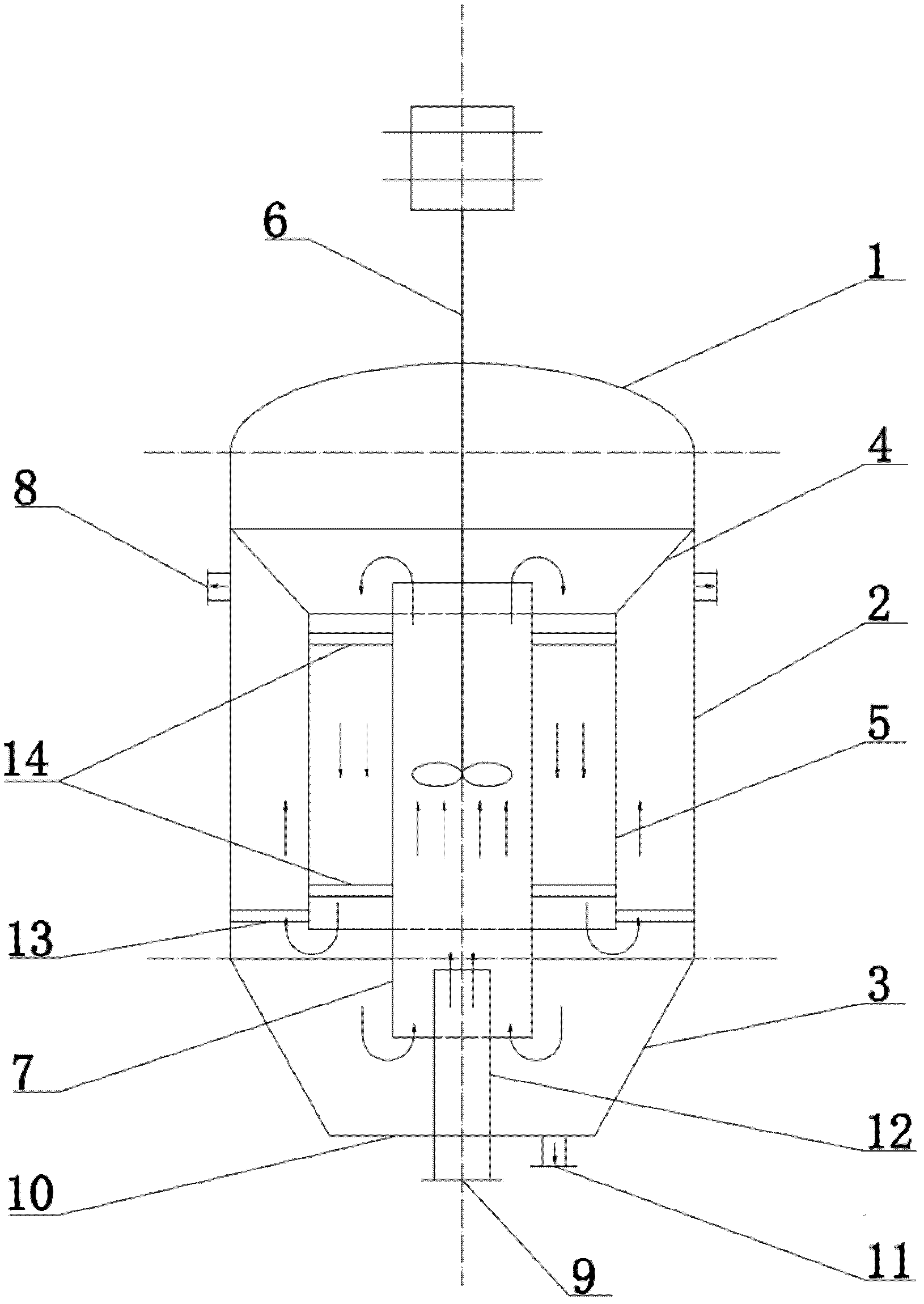

Method used

Image

Examples

Embodiment 1

[0027] After the synthetic reaction of tetraacetylethylenediamine is completed, the temperature of the material is controlled at 120°C; the volume of the continuous crystallizer is 5000L, and the weight of the material in the continuous crystallization tank is kept at 4000kg; The temperature difference between the inlet and outlet of the heater is 2°C, and the crystallization temperature is 10°C; the crystalline product is obtained by centrifugation, washing, and drying; the purity of the product is tested by HLPC, and the color is tested by Lab mode.

Embodiment 2

[0029] Adjust the rate of incoming and outgoing materials to 400kg / h, control the flow rate of the circulation pump to 22040kg / h, and the temperature difference between the inlet and outlet of the heat exchanger to 2°C, and the rest of the conditions are the same as in Example 1.

Embodiment 3

[0031] The rate of incoming and outgoing materials was controlled to 400kg / h, the flow rate of the circulating pump was 8040kg / h, the temperature difference between the inlet and outlet of the heat exchanger was 5°C, and the crystallization temperature was 20°C. The rest of the conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com