Degassing equipment

An equipment and degassing technology, applied in liquid degassing, sampling devices, chemical instruments and methods, etc., can solve the problem that the working track of the pressure roller is not a full circle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

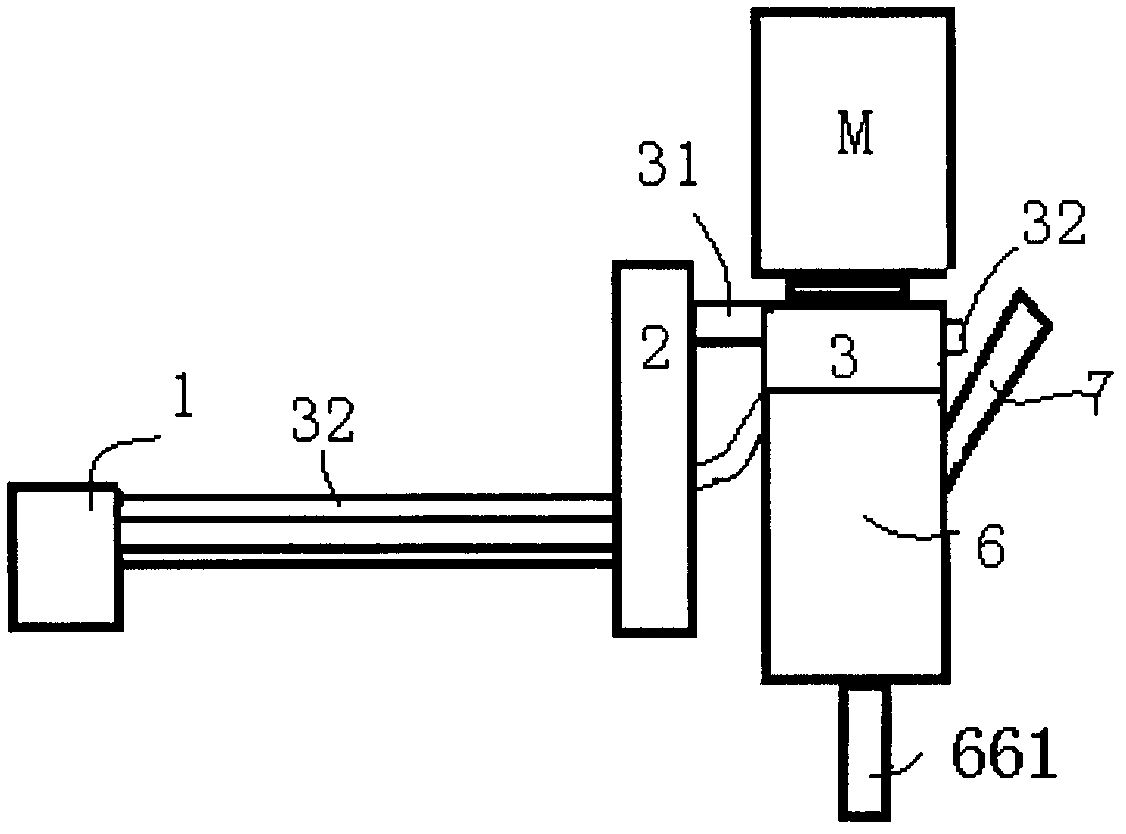

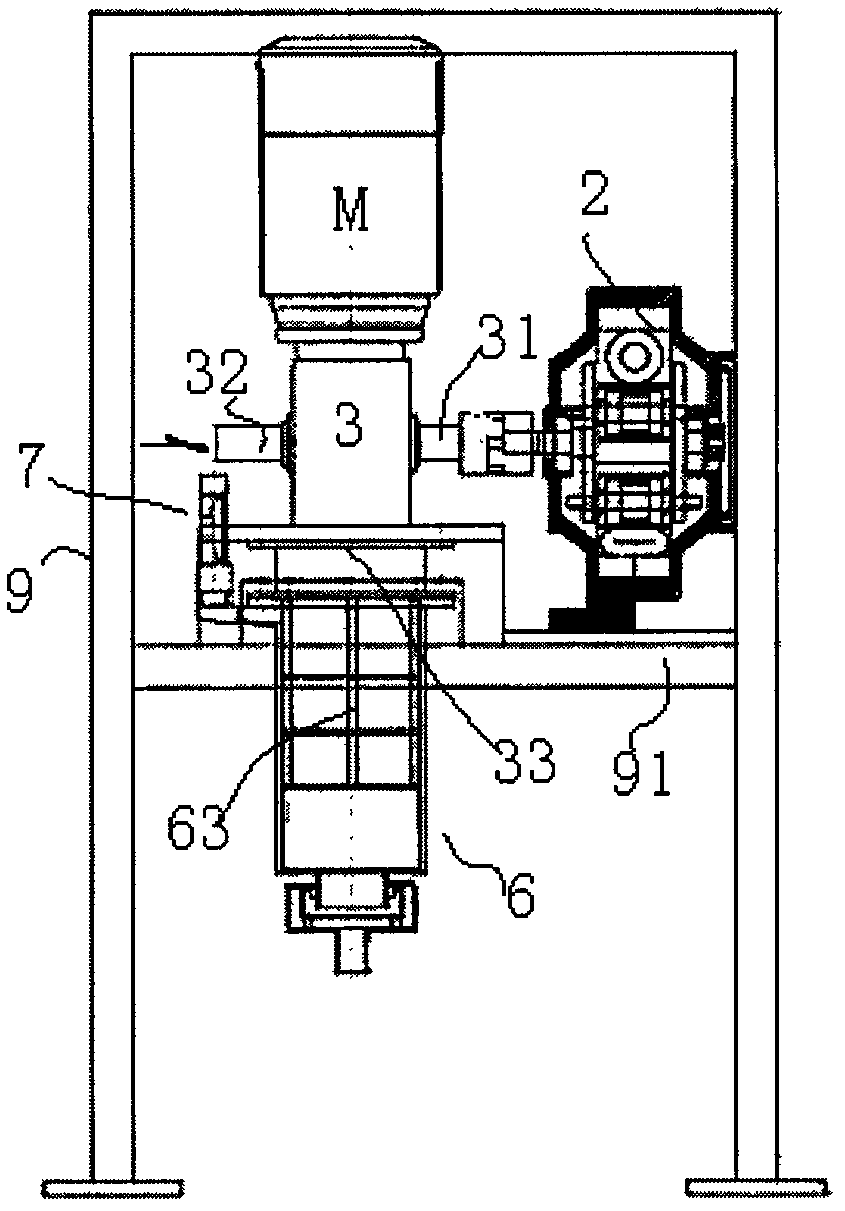

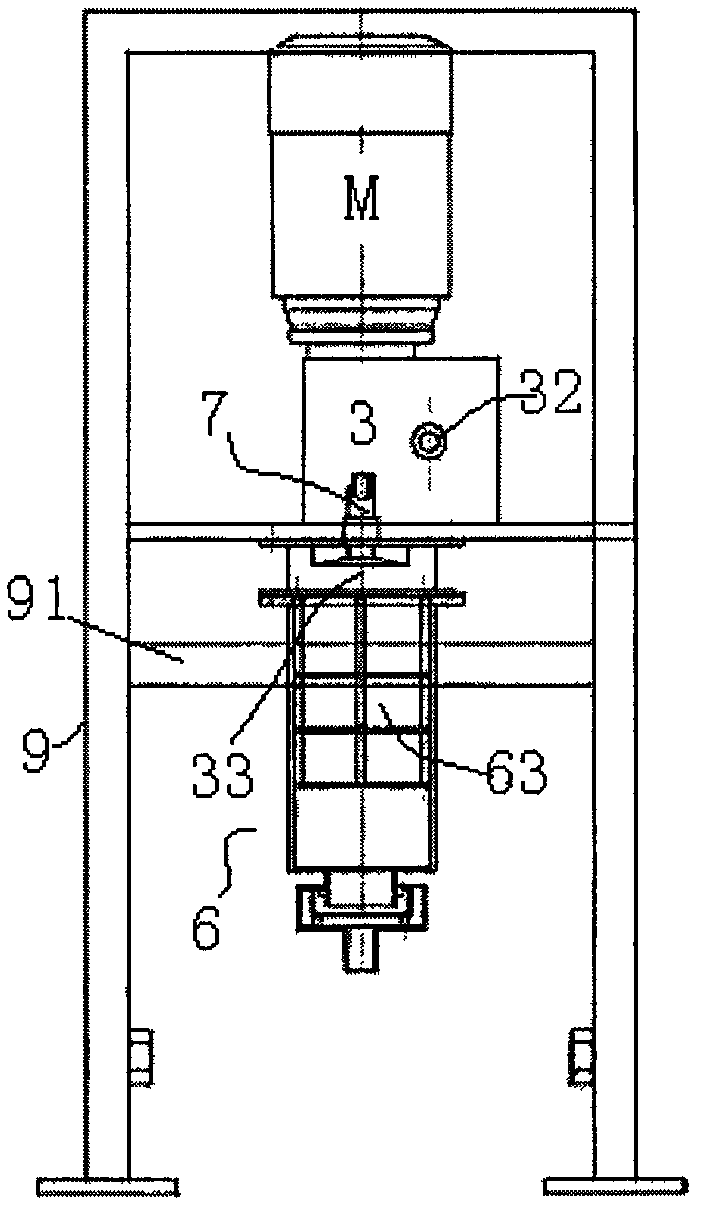

[0089] see Figure 1-10 As shown, a degassing device and its liquid suction structure and liquid suction head.

[0090] see Figure 1-4 , the degassing equipment has a power output unit, a degasser 6 (also known as a degasser), a hose pump 2, a liquid suction head 1, and the liquid suction head 1 is installed on the hose pump 2, and the liquid suction head It is a device for sucking mud from drilling. The hose pump is connected to the degasser. The mud sucked by the liquid suction head is pumped into the degasser for degassing through the hose pump. The degassed gas is sent in through the exhaust pipe 7. Mud logg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com