Single-arc twin-wire pipeline all-position welding method

A technology of single-arc double wire and welding method, which is applied to welding equipment, arc welding equipment, tubular objects, etc., can solve the problems of difficult adjustment and welding seam fusion welding parameters, etc., so as to increase filling amount, shorten welding time, improve The effect of welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

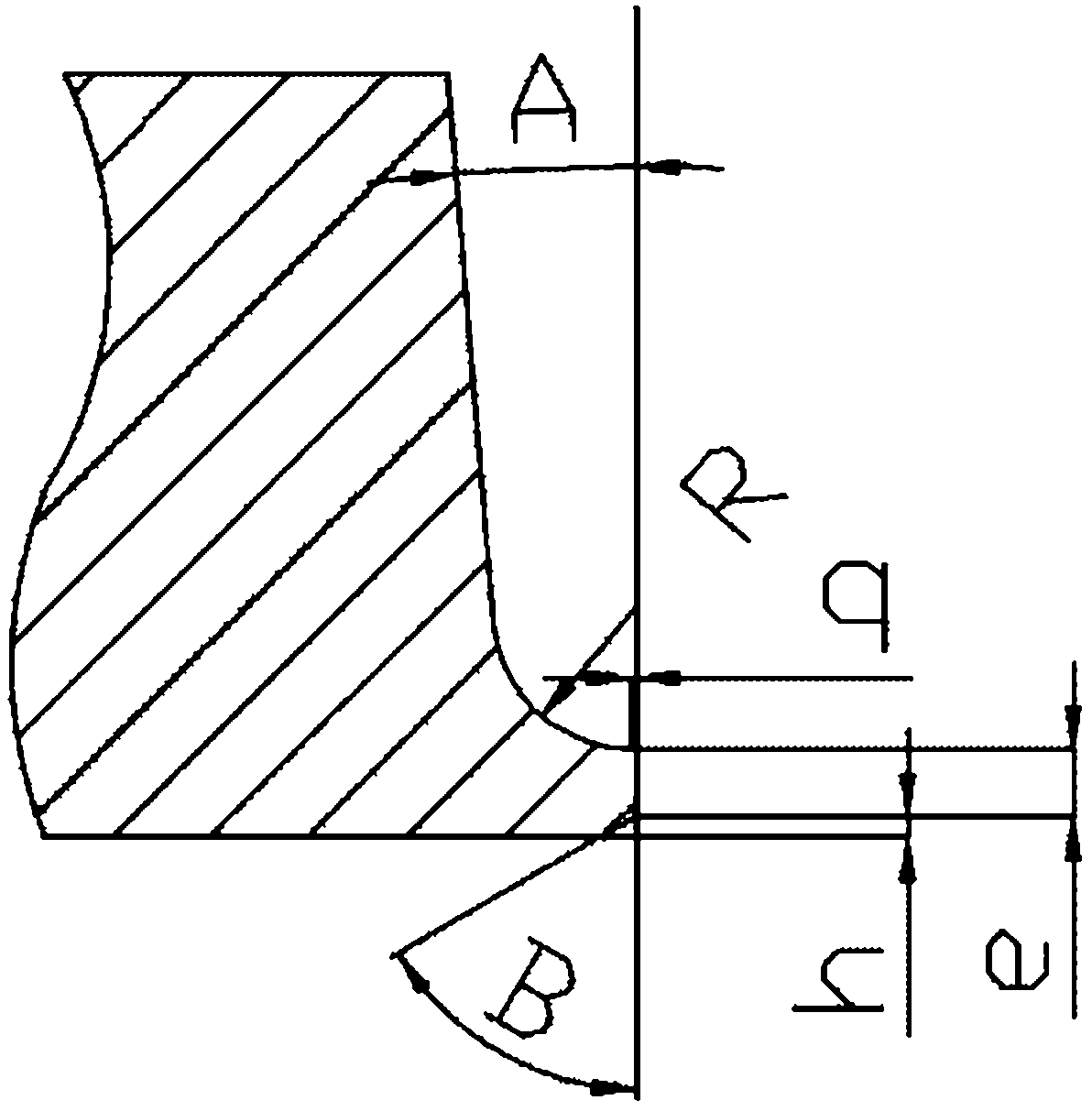

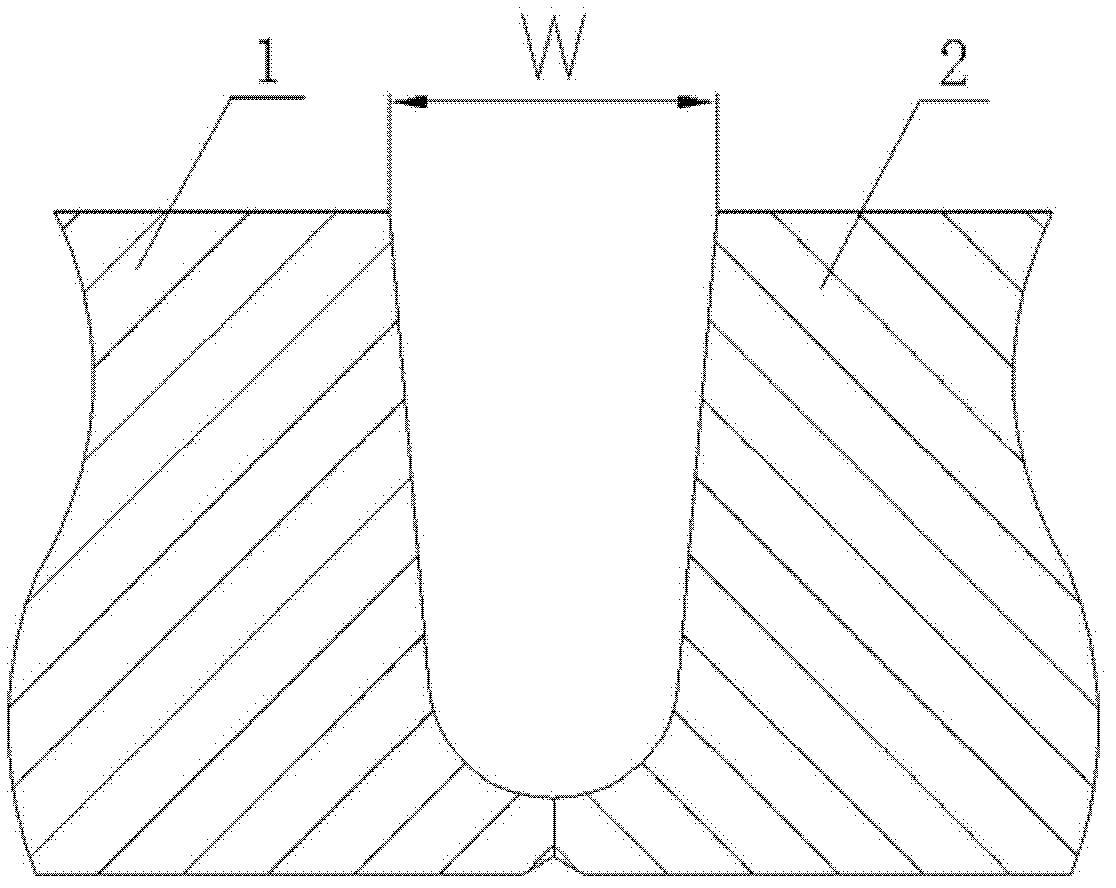

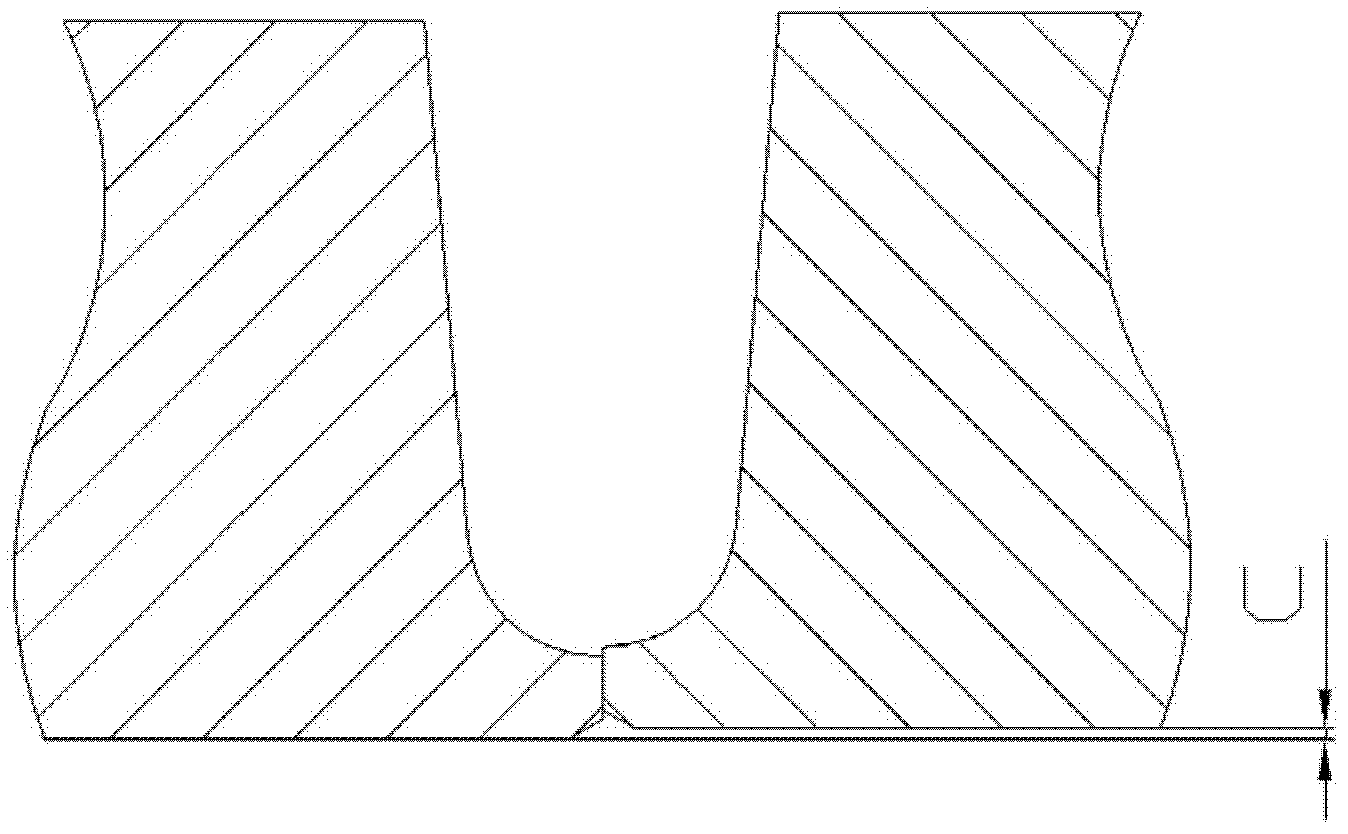

[0014] In the pipeline automatic welding process, due to the high welding current density of the single-arc double-wire non-rotating pipeline girth weld all-position automatic welding machine, the natural melting width of the molten pool is large, so it can be used to solve various defects in the weld, and also It has the characteristics of wide adaptable range of welding parameters and high construction efficiency. The embodiment of the present invention uses the welding process of the automatic welding machine to realize all-position welding of single-arc double-wire pipelines, so as to solve defects such as weld incomplete fusion, slag inclusion and air holes in the existing all-position automatic welding process. The following is an example of an oil and gas pipeline with a wall thickness of 17.5mm, a diameter of Φ1016, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com