Forklift-based sauce jar delivering and overturning mechanism

A technology for a forklift and a sauce tank is applied in the field of a forklift conveying and turning sauce tank mechanism, which can solve the problems of inability to meet production requirements, high labor intensity, low work efficiency, etc., and achieve the effects of reducing potential safety hazards, low labor intensity, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

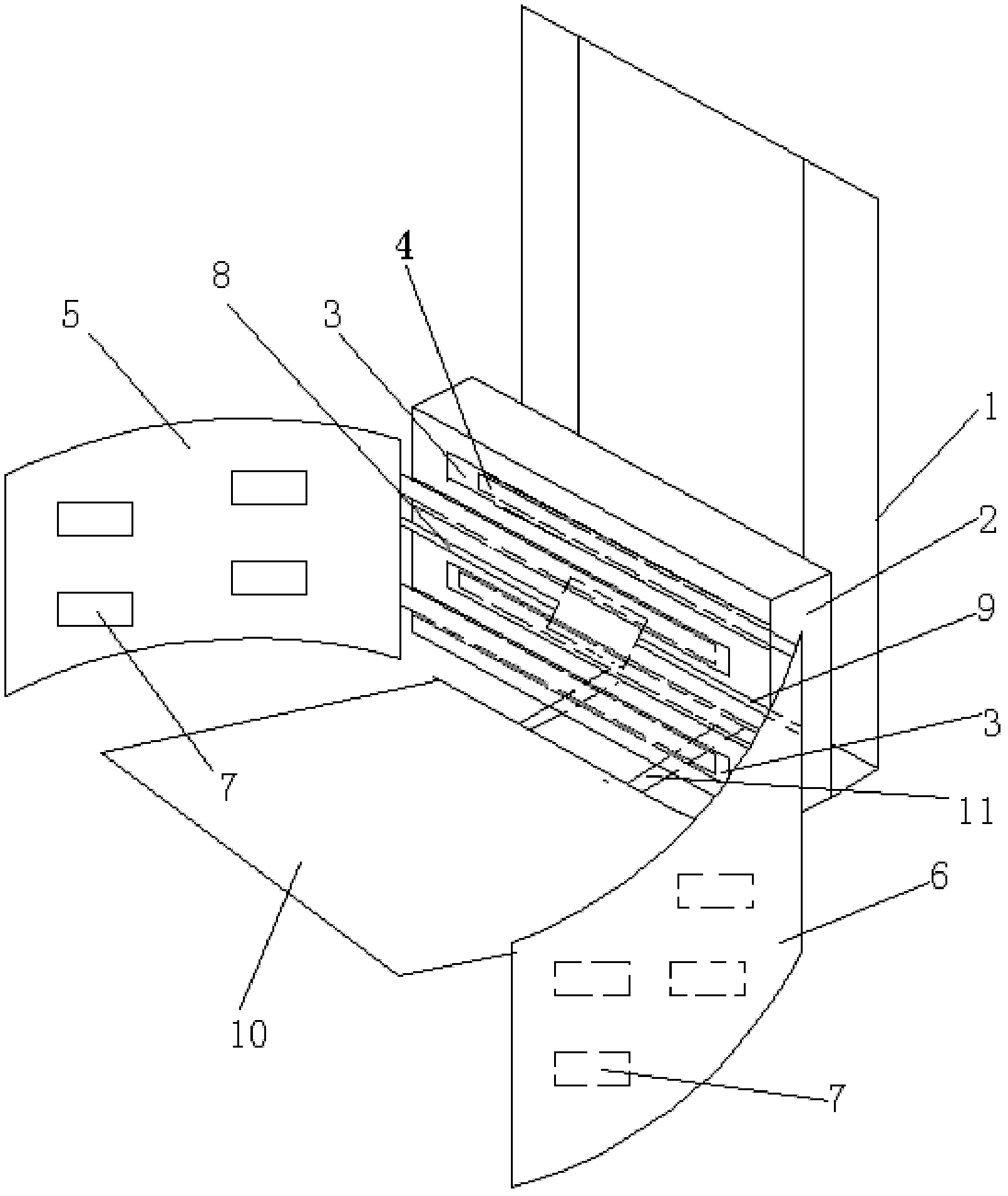

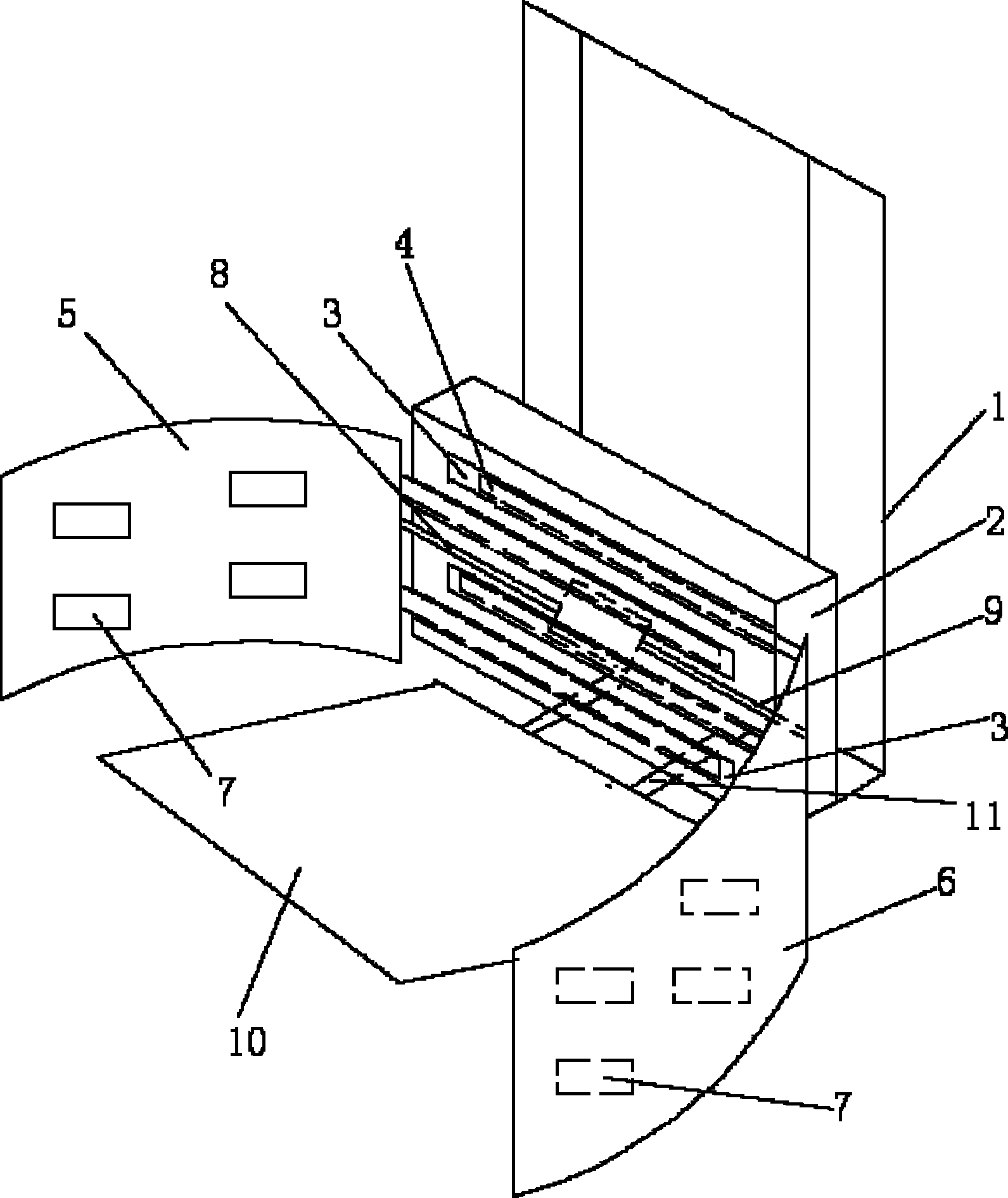

[0013] Referring to the accompanying drawings, a forklift structure for transporting overturned sauce jars includes a forklift body 1 with a turning function, and the turning of the mounting frame 2 at the front end of the forklift body 1 is driven by a motor, and the mounting frame 2 is provided with four guide grooves 3 , also includes left and right splints 5,6, the upper and lower ends of the rear end faces of left and right splints 5,6 are respectively provided with outwardly protruding guide rails 4, guide rails 4 and guide grooves 3 cooperate with each other, the middle part of mounting frame 2 A cylinder with double piston rods that drives the left and right clamps 5 and 6 plates to move is installed, and the ends of the two piston rods 8 and 9 of the cylinder with double piston rods are fixedly connected with the ends of the left and right clamps 5 and 6; Anti-slip rubber pads 7 are respectively installed on the corresponding surfaces of the left and right clamping pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com