Blow head of bottle-making machine

A technology of blowing head and bottle making machine, applied in the field of blowing head, can solve problems such as poor product, insufficient blowing, equipment failure, etc., and achieve the effect of reducing equipment maintenance, reducing programming time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

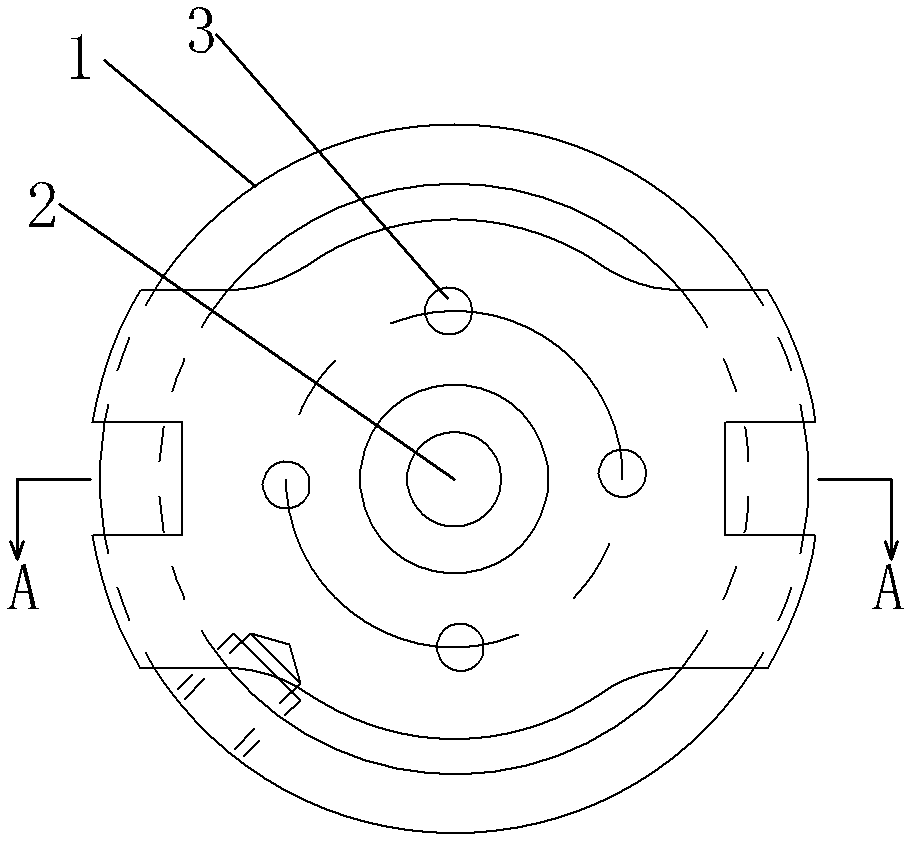

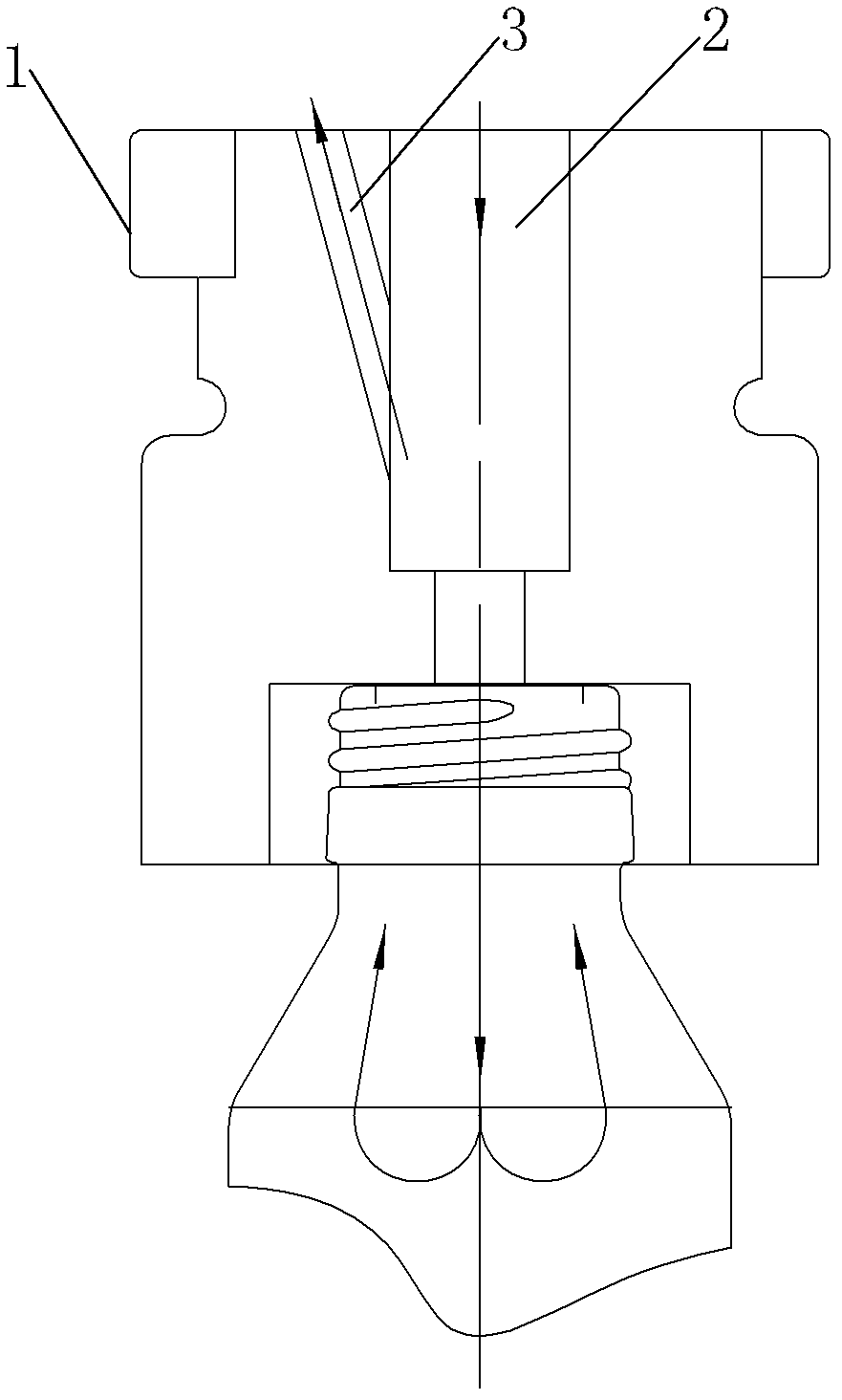

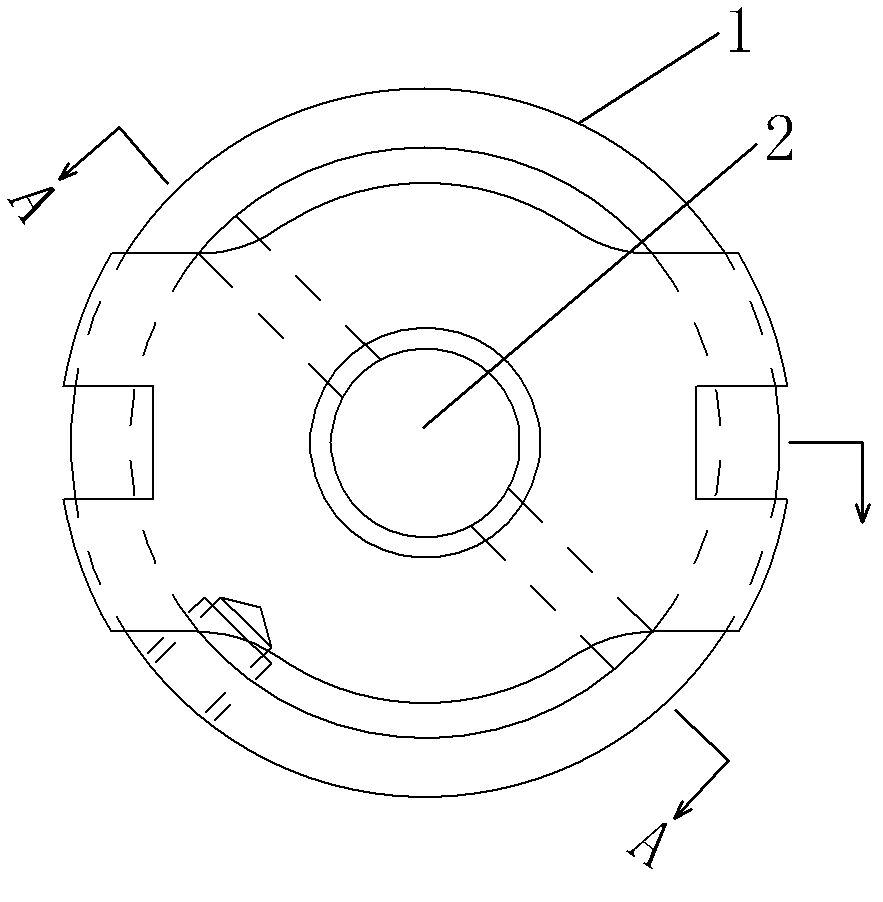

[0016] Embodiment: the blow head of a kind of bottle making machine of the present invention, as image 3 , 4 As shown, the air blowing head body 1 is included, the air intake pipe 2 is vertically opened at the center of the air blowing head body 1, and the air intake pipe 4 is inserted in the air intake pipe 2, and the root of the air blowing pipe 4 is connected with the air intake pipe 2. The entrance of the air blowing pipe is closely matched, and there is a gap 5 between the parts other than the 4 roots of the air blowing pipe and the inner wall of the air intake pipe 2, and the head of the air blowing pipe 4 is tapered.

[0017] In the blowing head body 1, there is an exhaust pipe 6 arranged obliquely. The exhaust pipe 6 is inclined 45 degrees relative to the horizontal plane. One end of the exhaust pipe 6 communicates with the middle part of the air intake pipe 2, and The other end leads to the outside of the blowing head body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com