Manufacturing method of three-dimensional glass shell

A technology for glass shells and manufacturing methods, applied in glass pressing, glass manufacturing equipment, glass molding, etc., can solve the problems affecting the area of the touch function area, the top surface of electronic products cannot be fully utilized, etc., and achieve rapid molding , to ensure the quality, the effect of rapid heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a further understanding of the object, structure, features and functions of the present invention, the detailed description of the embodiments is as follows:

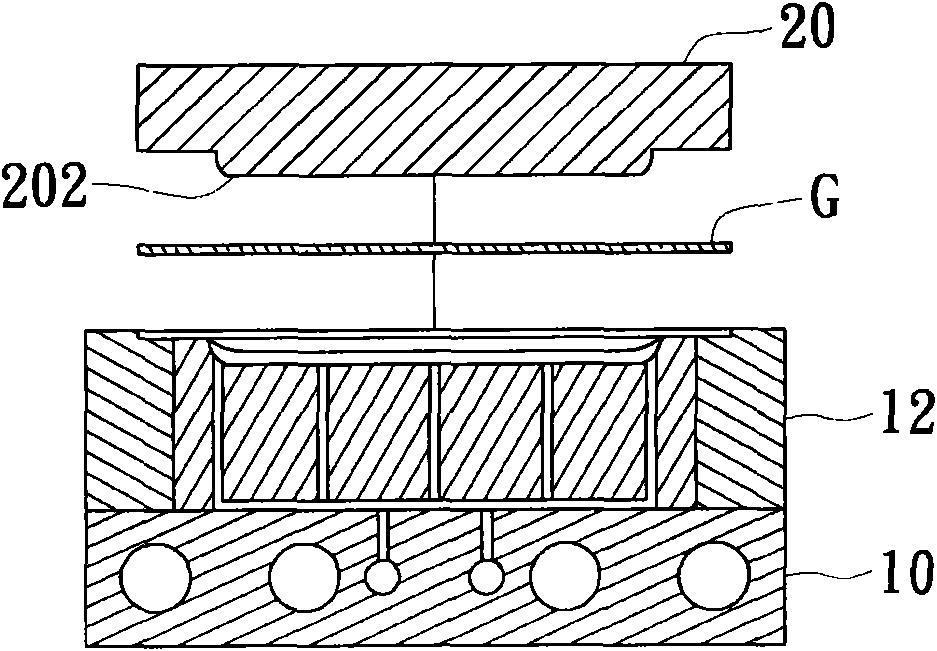

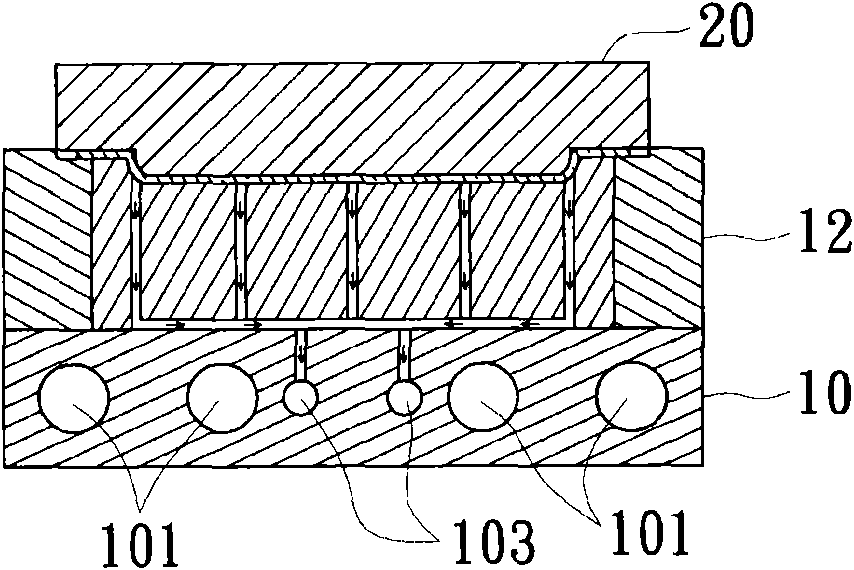

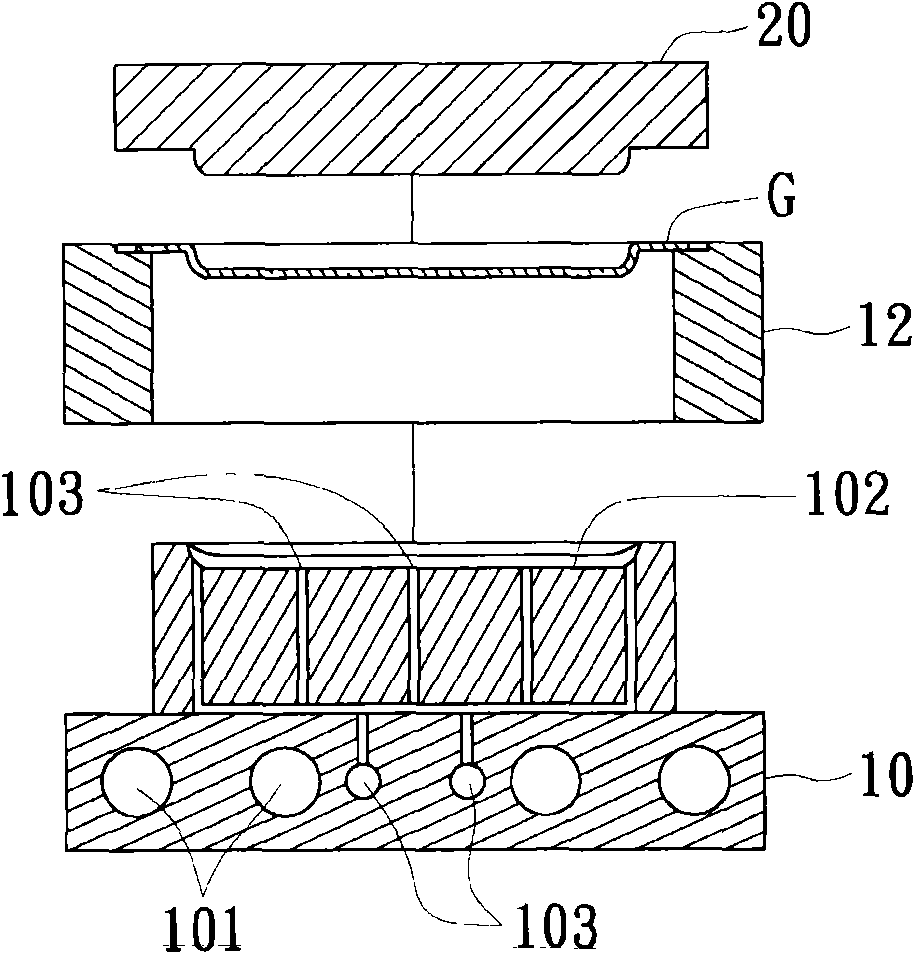

[0050] Please refer to Figure 1A to Figure 1C , is a schematic diagram of the steps of the manufacturing method of the three-dimensional glass case of the present invention.

[0051] The manufacturing method of the three-dimensional glass housing of the present invention comprises at least the following steps:

[0052] First, if Figure 1A As shown, a mold 10 is provided, and a molding surface 102 (such as Figure 1C ), the molding surface is the same as the glass shell G (such as Figure 1C As shown), the mold 10 is formed with at least one gas passage 103 communicating with the molding surface 102 .

[0053] Next, a picking device 12 is provided to pick up the edge of a flat glass case G. The present invention is particularly suitable for glass cases with a thickness of less than 1 mm, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com