Special composite oil phase for high-temperature sensitized and emulsified explosive production process

An emulsion explosive and production process technology, which is applied to explosives, non-explosive/non-thermal agent components, and offensive equipment, etc., can solve the problem that the detonation sensitivity and storage performance of explosives are reduced, the storage performance of explosives cannot be effectively guaranteed, and the explosives are affected. Detonation performance and storage performance, etc., to achieve the effect of obvious emulsification and superposition, reducing the tendency of free aggregation, good explosion performance and storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

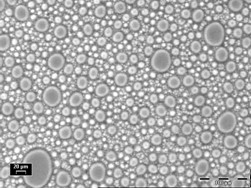

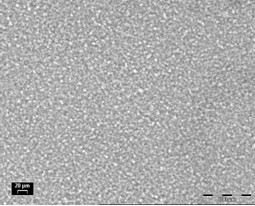

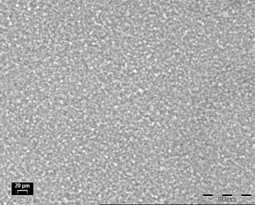

Image

Examples

Embodiment 1

[0041] The special composite oil phase formula for the production of high temperature sensitized emulsion explosives is:

[0042] Light deasphalted oil: 25%, paraffin wax: 5%, peak wax: 18%, petrolatum: 16%, SMO: 11%, emulsifier J: 25%.

Embodiment 2

[0044] The special composite oil phase formula for the production of high temperature sensitized emulsion explosives is:

[0045] Lightly dewaxed oil: 20%, paraffin: 10%, palm wax: 15%, petrolatum: 20%, SMO: 15%, emulsifier J: 20%.

Embodiment 3

[0047] The special composite oil phase formula for the production of high temperature sensitized emulsion explosives is:

[0048] Lightly deasphalted oil: 12%, lightly dewaxed oil: 11%, paraffin: 7%, ozokerite: 17%, vaseline: 17%, SMO: 13%, emulsifier J: 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com