Polysilicon silicon chip double-diffusion manufacturing method

A manufacturing method, polysilicon technology, applied in diffusion/doping, polycrystalline material growth, final product manufacturing, etc., can solve the problem of high impurity concentration on the silicon surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide a manufacturing method for the double diffusion of PN junctions made of polysilicon wafers. layer" problem.

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

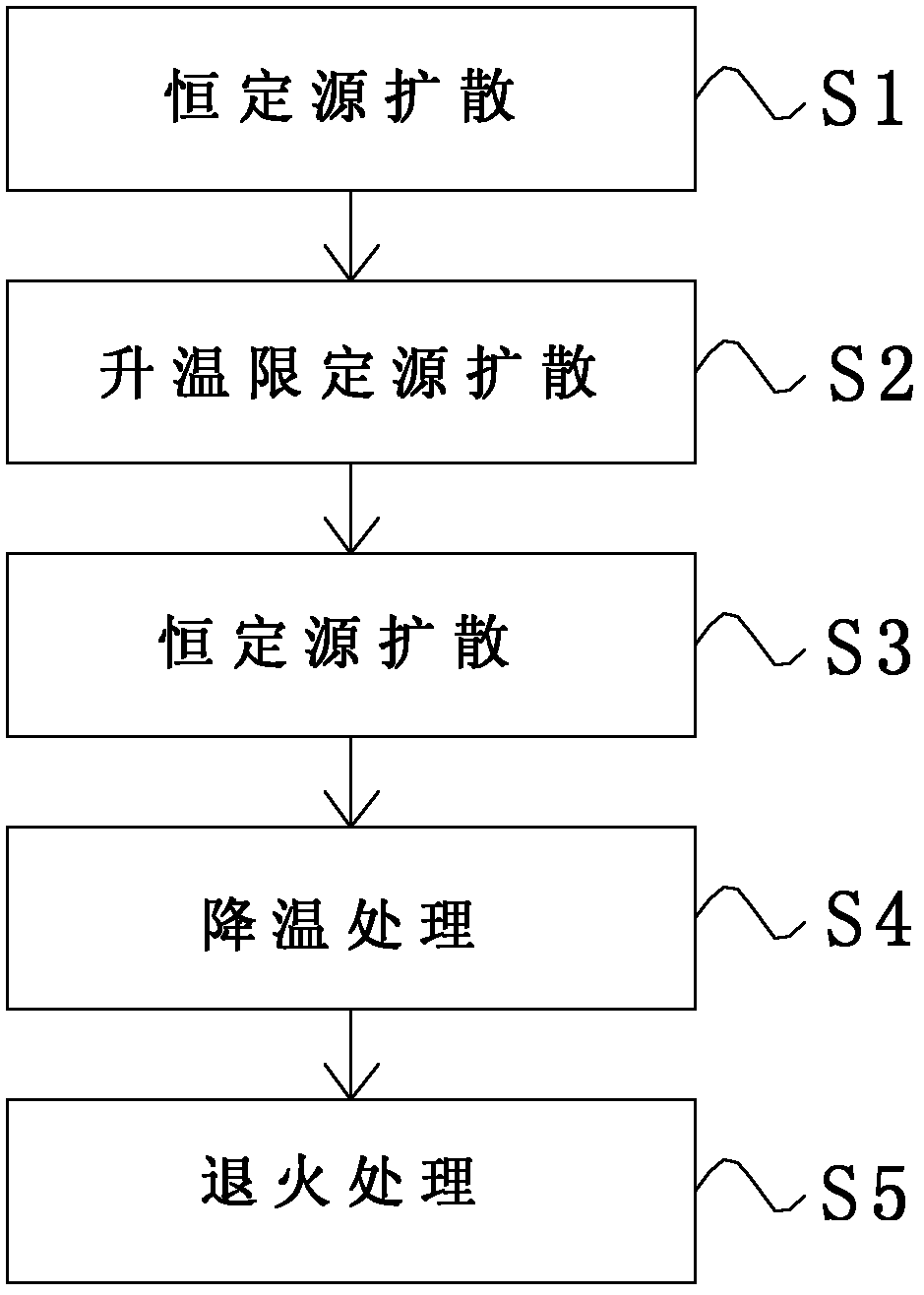

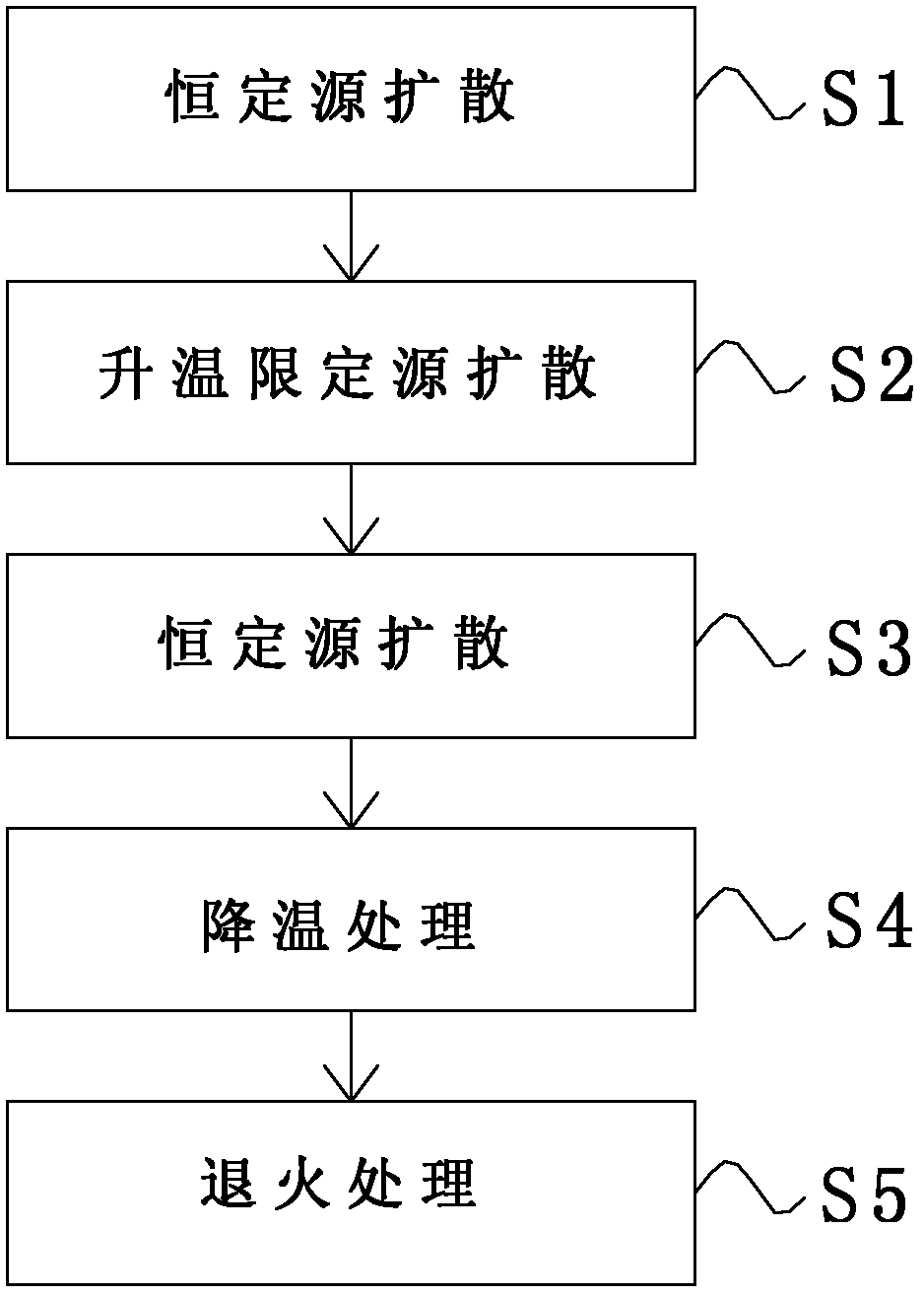

[0032] Please refer to figure 2 , figure 2 The flow chart of the double diffusion process of PN junction made of polysilicon wafer provided by the present invention.

[0033] The invention provides a manufacturing method of double diffusion of PN junction made of polysilicon wafer, the method comprises: step S1 constant source diffusion, step S2 temperature raising limited source diffusion, step S3 constant source diffusion. First of all, it is necessary to explain the relationship between the oxygen flux and the polysilicon wafer when the PN junction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com