Reusable reinforced concrete composite pile available for on-load segmental disassembly and construction method of reusable reinforced concrete composite pile available for on-load segmental disassembly

A combined pile and load-carrying technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of non-reusable, unfavorable low-carbon environmental protection, long construction period, etc., and achieve the effect of avoiding the cost of construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

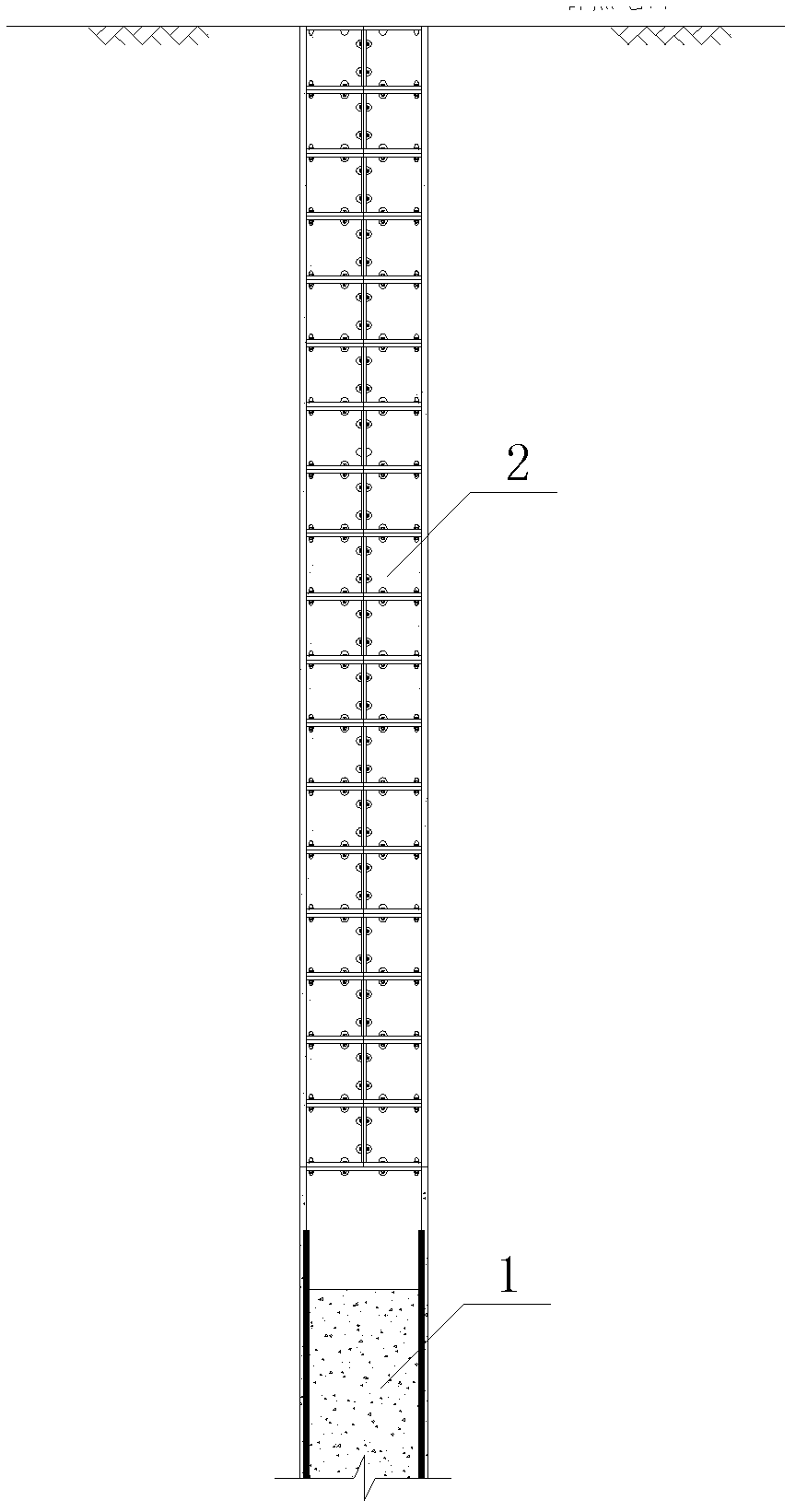

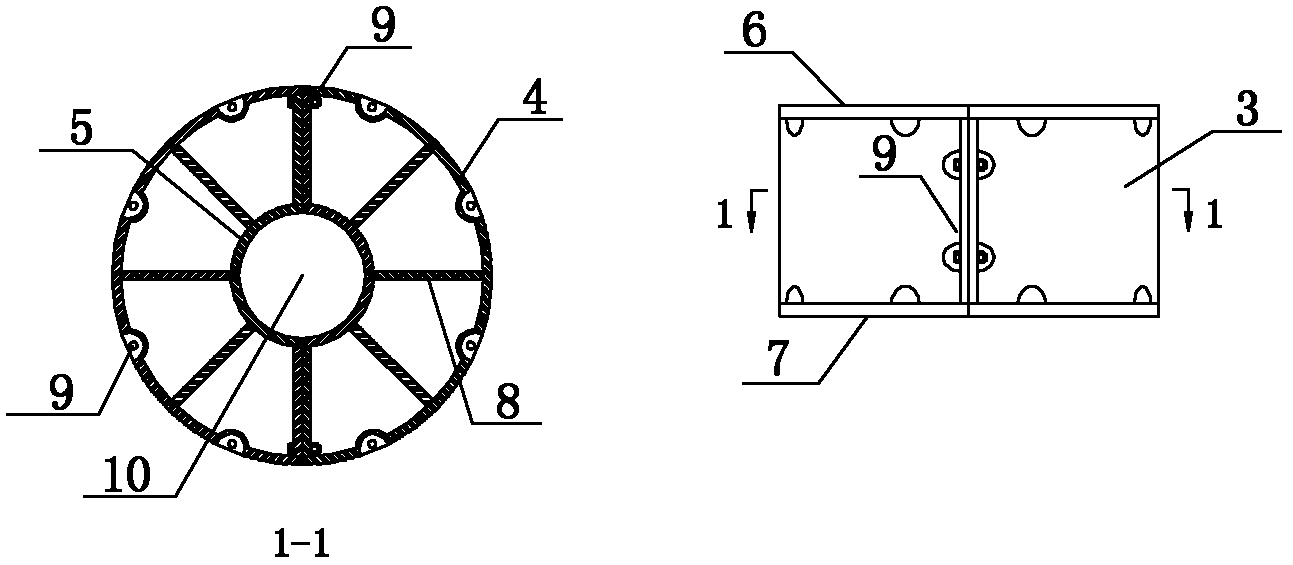

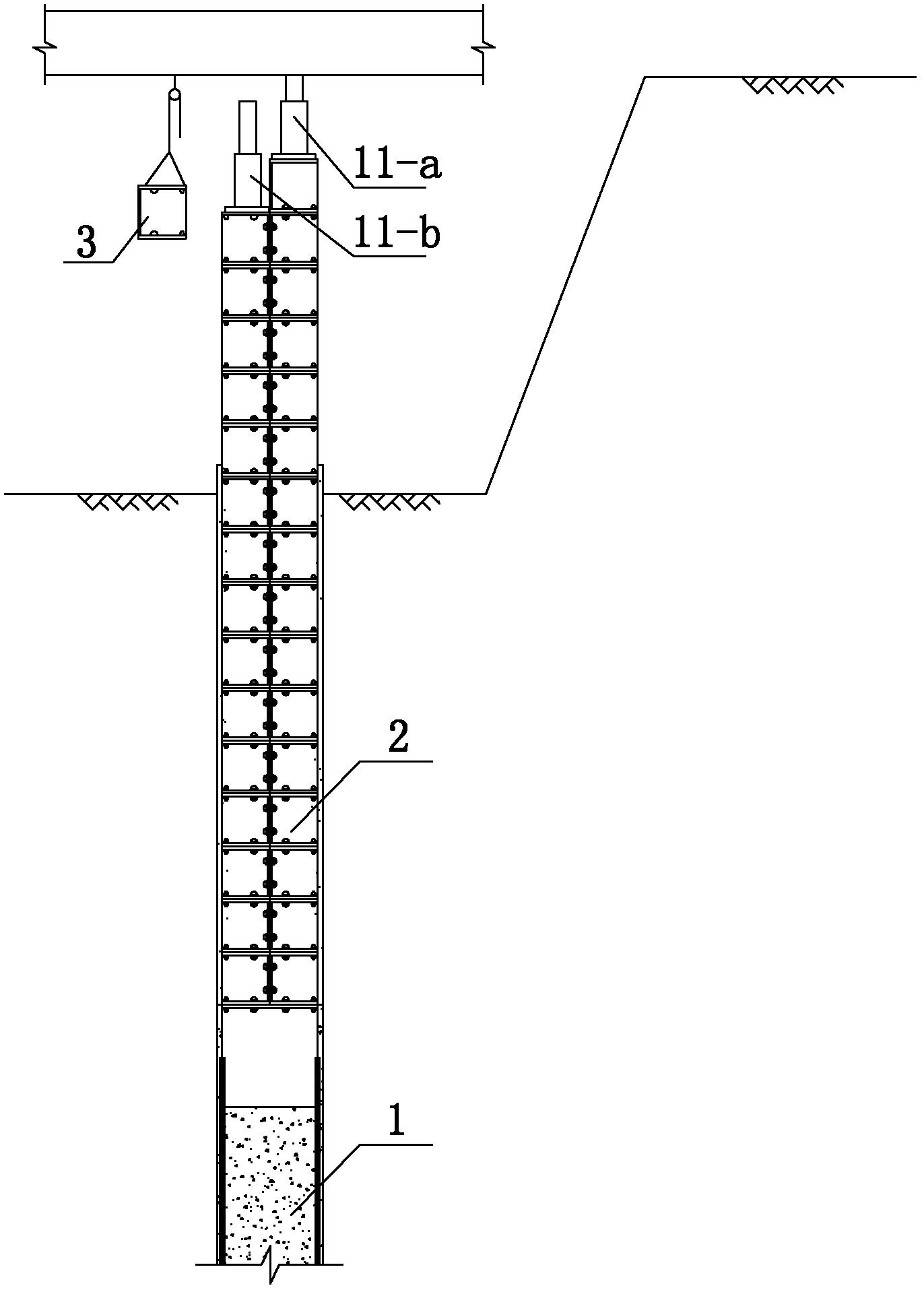

[0022] The following is a detailed description of the present invention in combination with specific embodiments as follows: figure 1 As shown in the schematic diagram of the pile body section of the composite pile, the steel-concrete composite pile that can be dismantled in sections and can be reused under load includes the lower reinforced concrete pile body 1 and the upper steel box structure pile body 2, and the upper steel box structure pile body 2 A pile body with a bearing section is formed by connecting and combining several unit steel boxes 3 through a connecting piece 9. Such as figure 2 As shown in the schematic diagram of the unit steel box assembly, the transverse section of the steel box structure pile 2 is divided into two symmetrical semi-circular arc unit steel box panels 6 as the load bearing surface of the pile top. Such as image 3 , 4 As shown in the schematic diagram of the sectional disassembly of the combined pile under load, the steel box structure pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com