Valve component for four-valve diesel

A diesel engine and four-valve technology, which is applied to the lubrication of engine components, mechanical equipment, and valve accessories, can solve problems such as valve stem manufacturing errors, valve bridges that cannot be leveled, and valve bridges that are inclined, and achieve the effect of ensuring lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

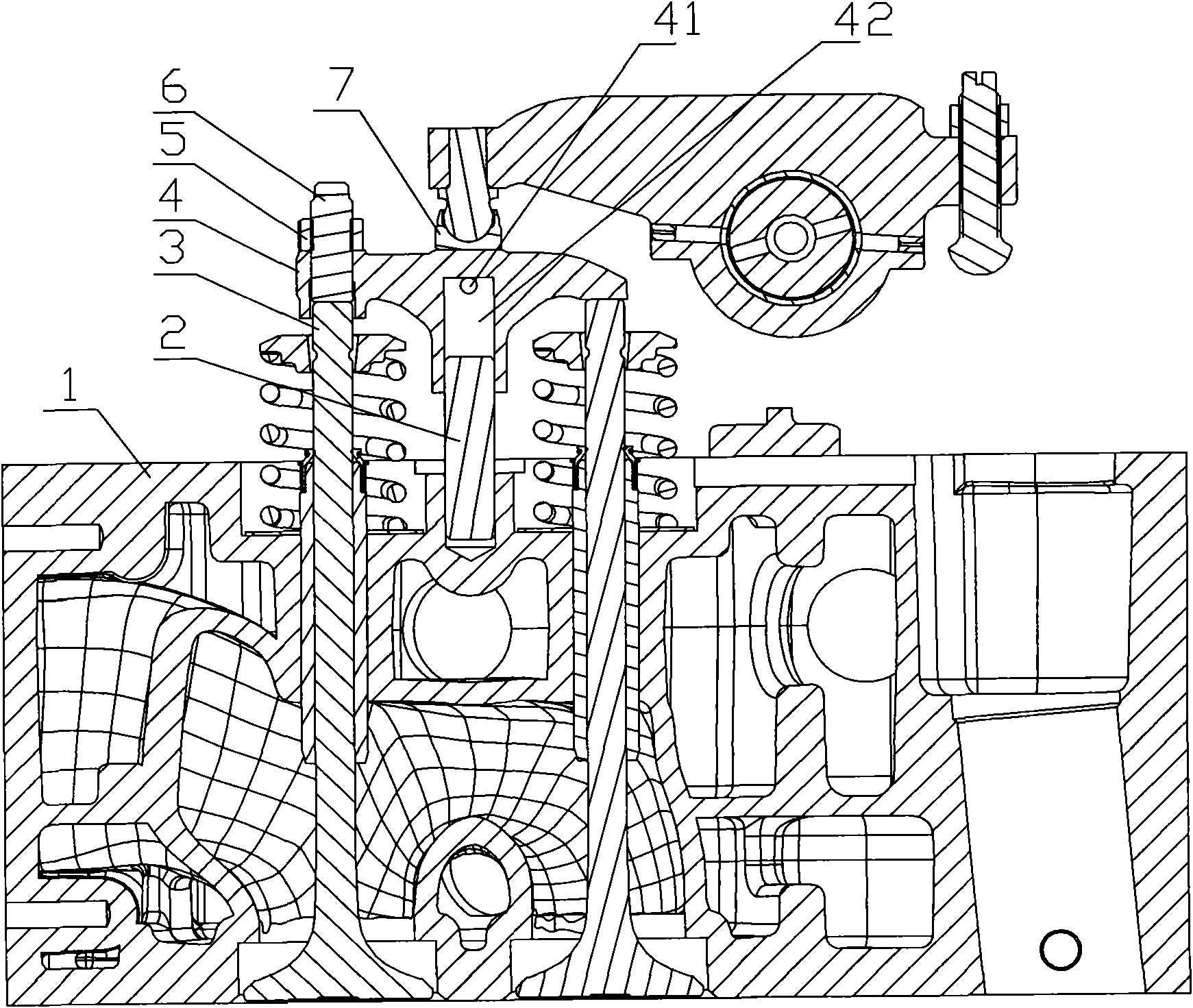

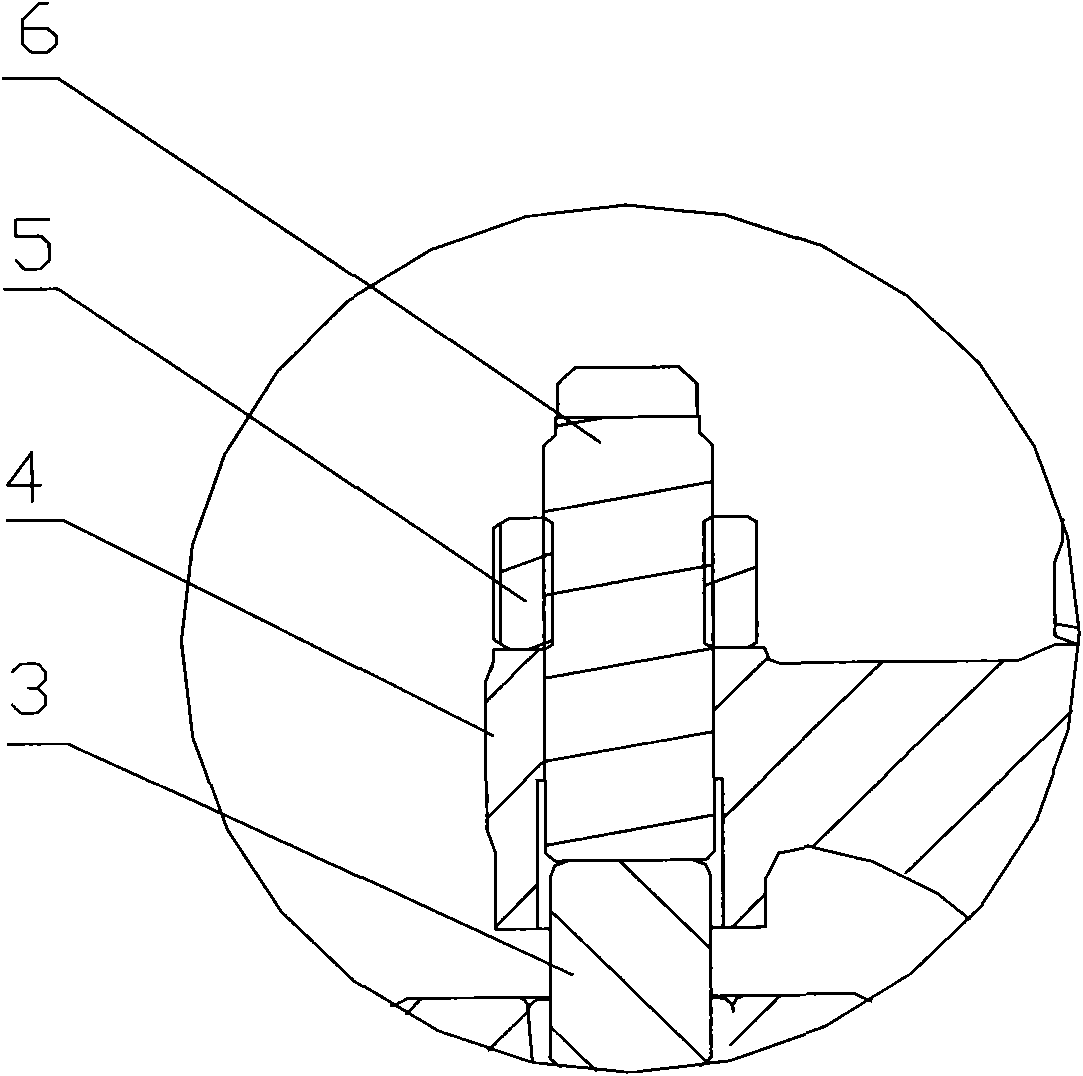

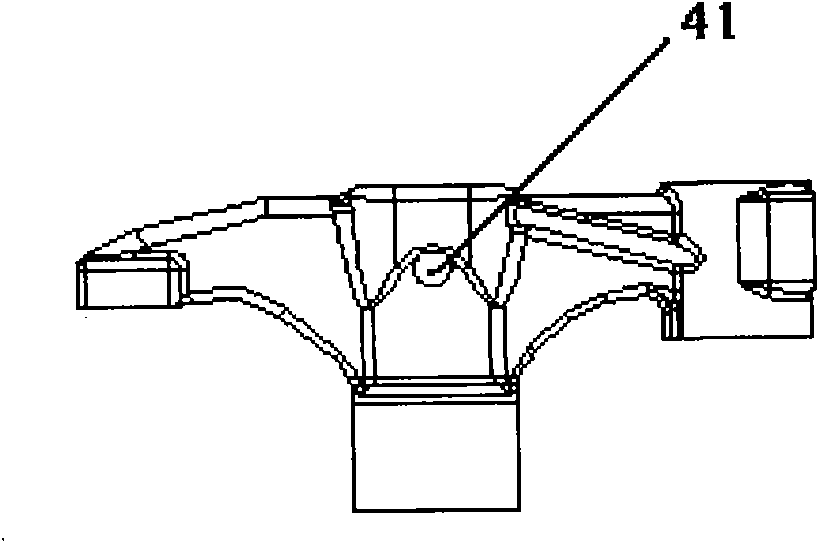

[0020] Such as figure 1 As shown, the valve assembly for a four-valve diesel engine of the present invention includes a valve bridge 4 and an exhaust valve 3 positioned at both ends of the valve bridge 4, and the top of the exhaust valve 3 is in contact with the valve bridge 4 (can realize the lowering of the valve bridge to the exhaust valve) pressure); the valve bridge 4 presses down the valve bridge under the action of the rocker arm to push the exhaust valve 3 at both ends to move downward together, and the exhaust valve 3 opens at this time; the downward thrust of the rocker arm is not enough to overcome the restoring force of the valve spring At this time, the exhaust valve 3 and the valve bridge 4 at both ends move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com