Mechanical booster clutch of electrically controlled silicone oil

A technology of mechanical supercharging and clutch, applied in the field of clutch, to achieve the effect of small external influence, high control precision and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

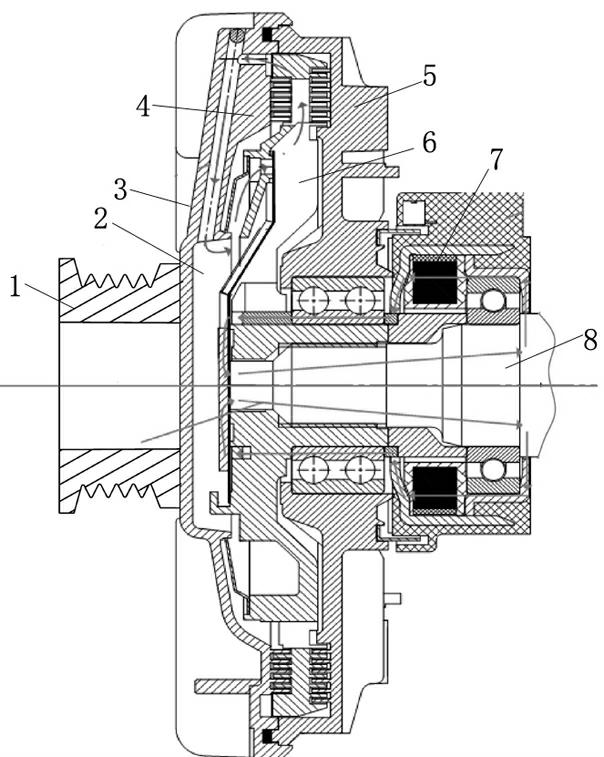

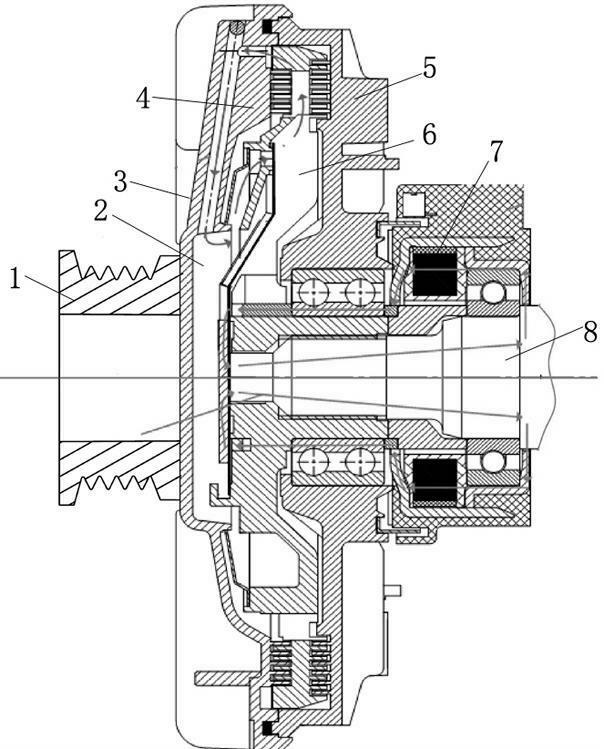

[0016] Such as figure 1 As shown, an electronically controlled silicon oil mechanical supercharged clutch includes a hydraulic coupling, and the hydraulic coupling includes a drive shaft 1 driven by a crankshaft, a pump wheel 5, a rotating casing 3, and a turbine wheel axially opposite to the pump wheel 1. Drive the driven shaft 8 of the supercharger, the flow channel 6 formed between the turbine and the pump wheel, and the auxiliary oil chamber 2 formed between the rotating housing and the outer side of the turbine. The auxiliary oil chamber communicates with the flow channel at the outer edge, and the flow channel Partially filled with silicone oil, the inner side of the upper blade area of the turbine is provided with an oil hole connecting the auxiliary oil chamber and the flow channel and a valve to control the opening of the oil hole.

[0017] When the oil hole is closed, the driven shaft does not move; as the opening of the valve increases, the speed of the driven sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com