Carbon tank three-way connecting device and connecting structure thereof in supercharged gasoline motor car

A technology for connecting device and carbon canister, which is applied in the fields of engineering components and mechanical engineering, can solve the problems of a large number of connecting joints, the carbon canister cannot be desorbed and lose its function, and achieves scientific and reasonable design, improved desorption efficiency, Easy-to-connect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

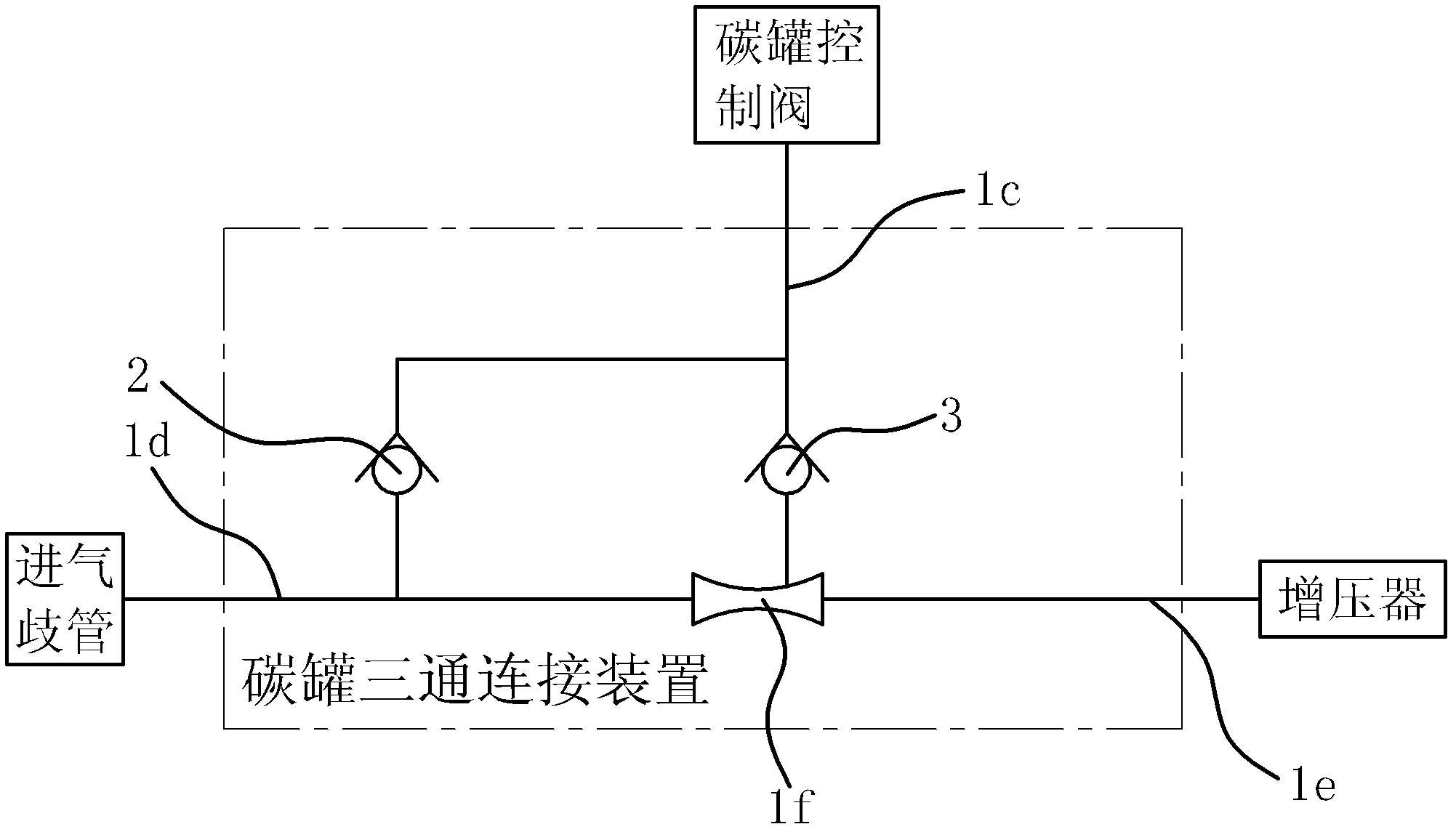

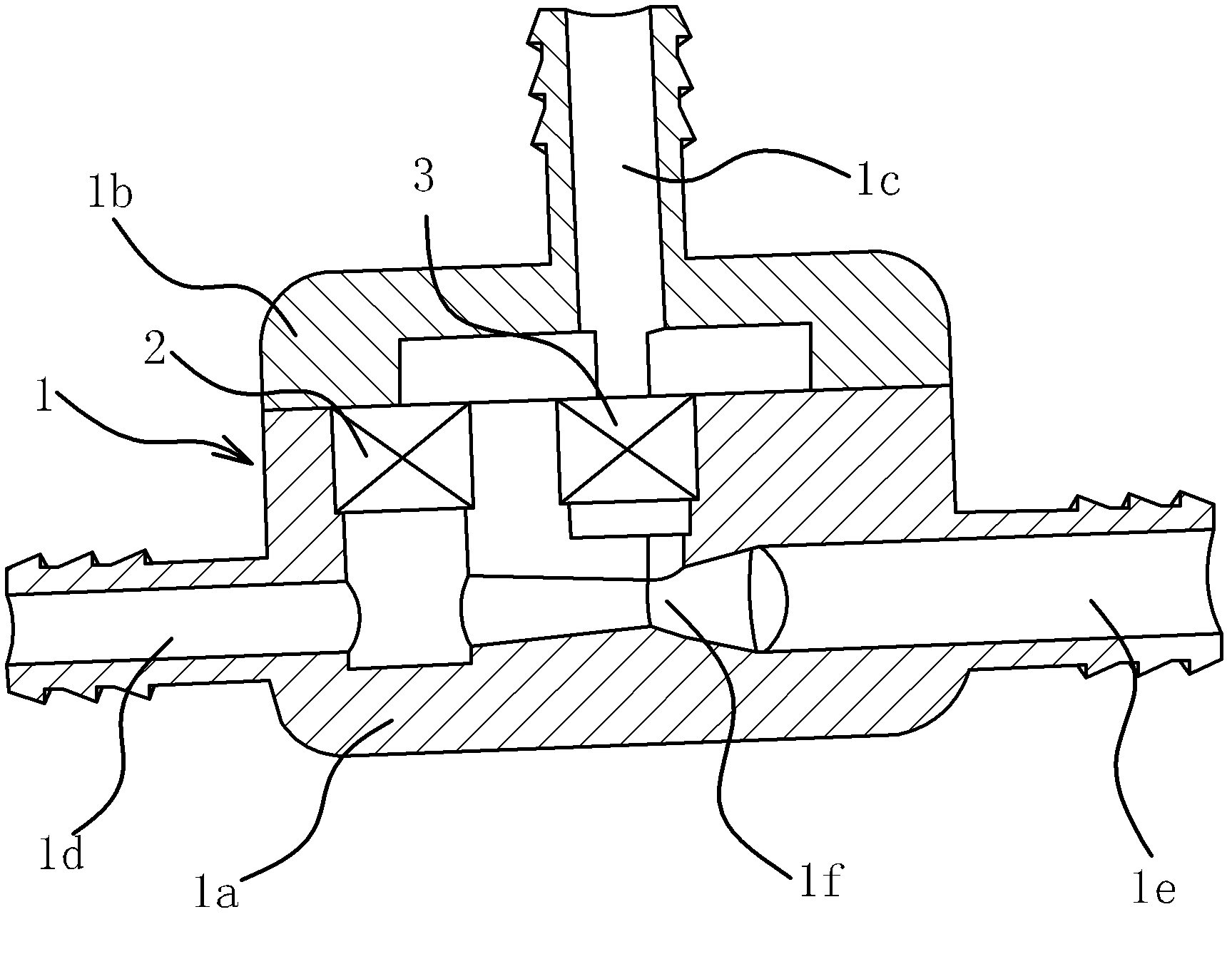

[0032] Such as figure 1 with figure 2 As shown, the carbon canister three-way connection device includes a connection body 1 with three interfaces and a one-way valve. The connection structure of the carbon tank three-way connection device in the supercharged gasoline vehicle includes connecting the three interfaces in the carbon tank three-way connection device with the corresponding pipelines in the carbon tank desorption circuit.

[0033] Specifically, as figure 1 , figure 2 with Figure 5 As shown, the connecting body 1 includes a base 1a and a top cover 1b sealed and fixedly connected with the base 1a; the first interface 1c is located in the top cover 1b; the second interface 1d and the third interface 1e are both located in the base 1a. In this embodiment, the second interface 1d and the third interface 1e are located on the same straight line, and the first interface 1c is perpendicular to the second interface 1d.

[0034] The first port 1c and the second port 1...

Embodiment 2

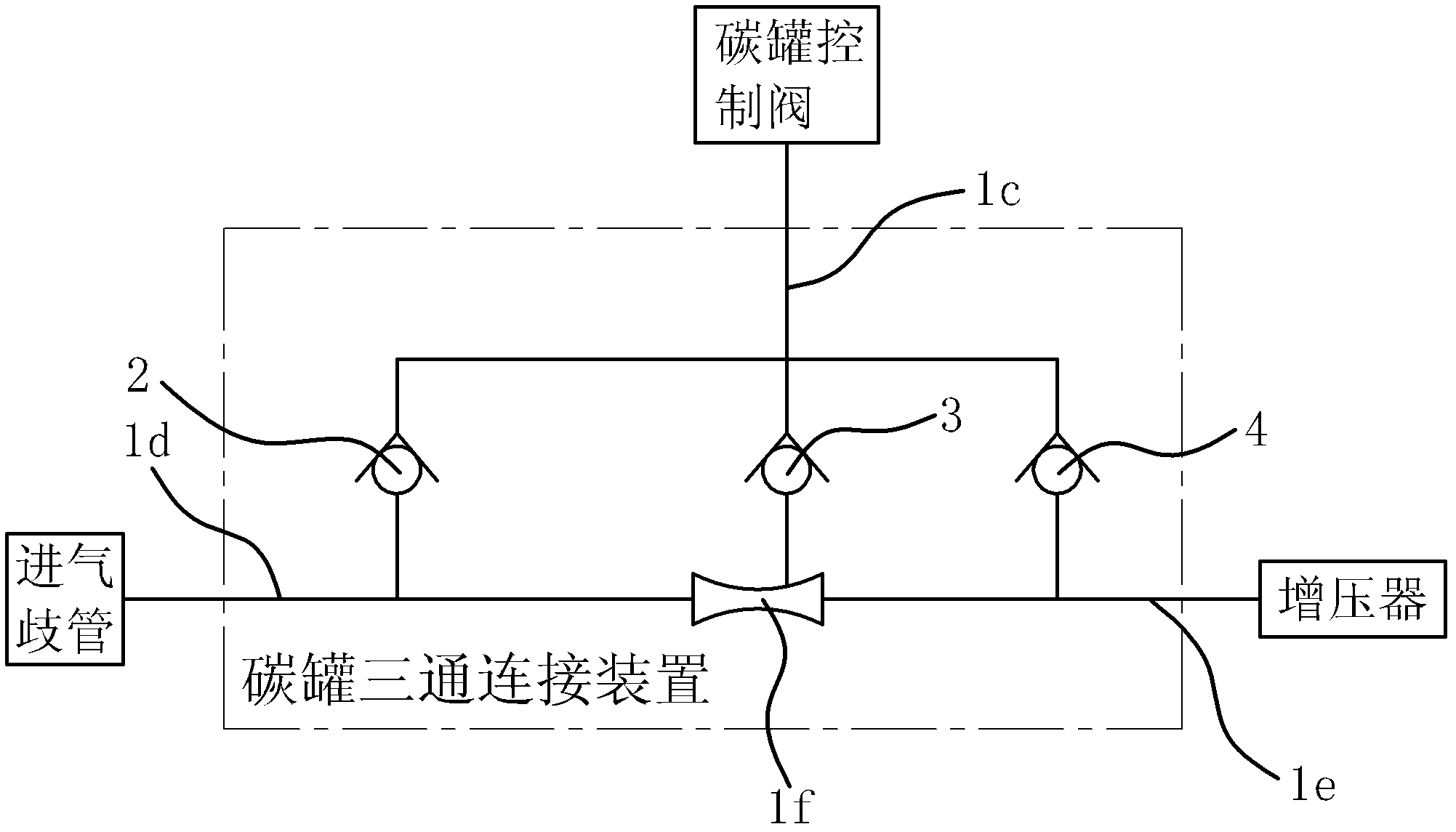

[0042] Such as image 3 and Figure 4 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference lies in: the medium can only flow from the first interface 1c to the third interface 1e by passing between the first interface 1c and the third interface 1e The one-way valve three 4-phase connection. When the pressure difference between the inlet and the outlet of the one-way valve three 4 is greater than 70-200Pa, the one-way valve three 4 is in a connected state. The cracking pressure values of check valve three 4 and check valve one 2 are basically the same. There is also a groove on the connection surface between the base 1a and the top cover 1b, and the one-way valve 34 is fixed in the above-mentioned groove of the base 1a.

[0043] When the vehicle is running at idle speed, when the pressure difference between the second interface 1d and the first interface 1c is relatively large, the pressure difference betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com