Cold-rolling flying shear synchronous connection shaft device and manufacture method

A technology of synchronous connection and shaft device, applied in the direction of shearing device, device for shearing and forming blanks, manufacturing tools, etc., can solve the problem of reducing the production capacity of cold rolling processing line, unfavorable daily maintenance of cold rolling flying shears, single long axis Problems such as difficult processing, to achieve good universality and operability, strong on-site operability, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

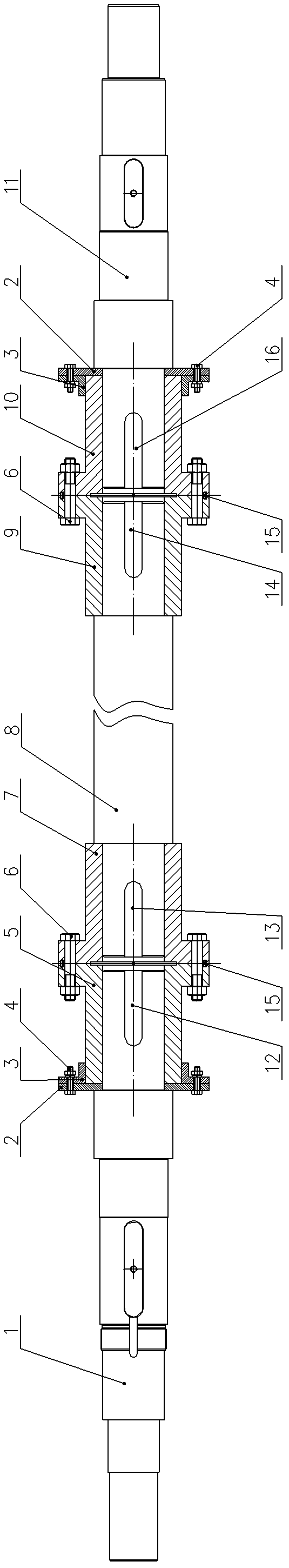

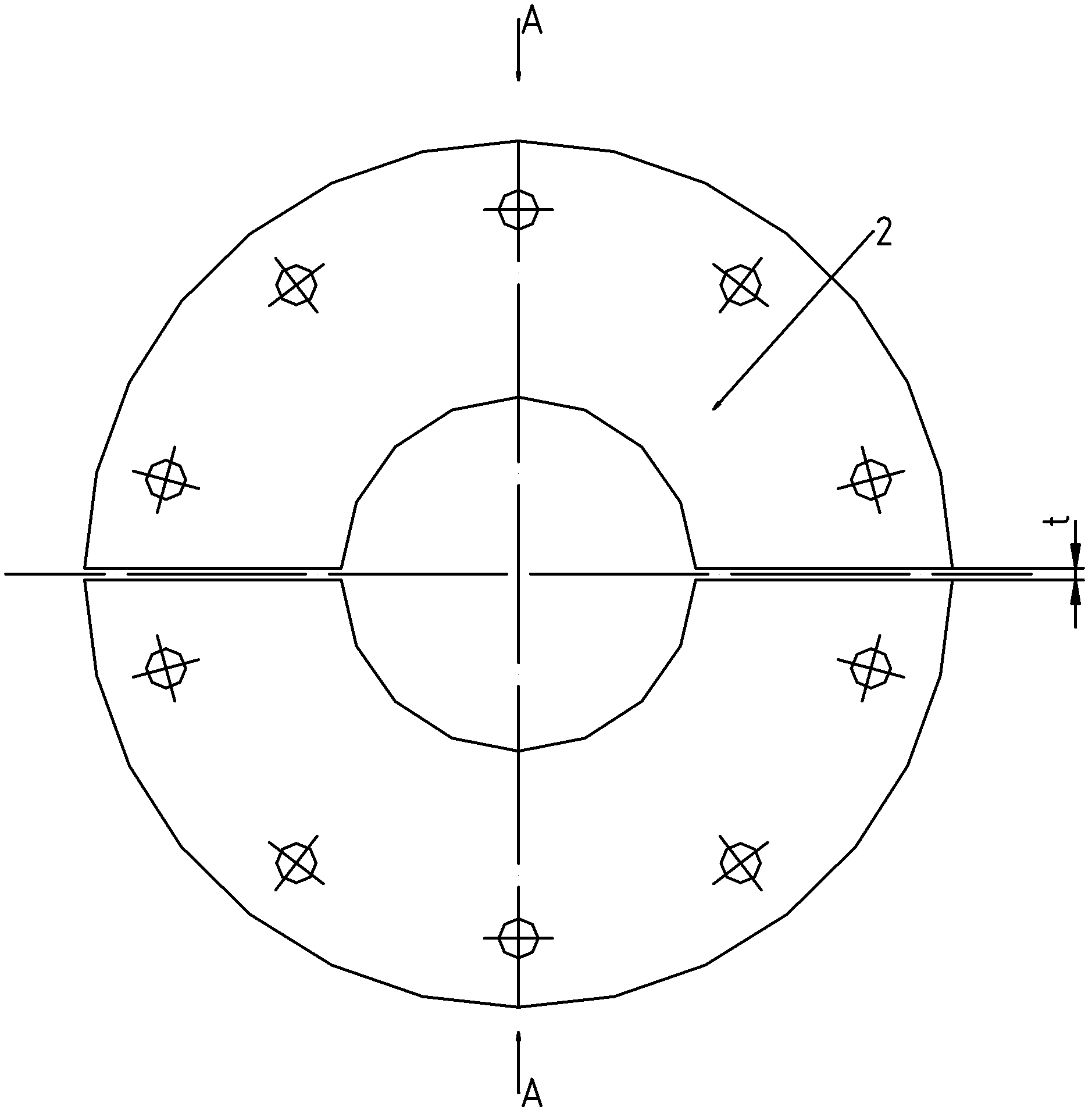

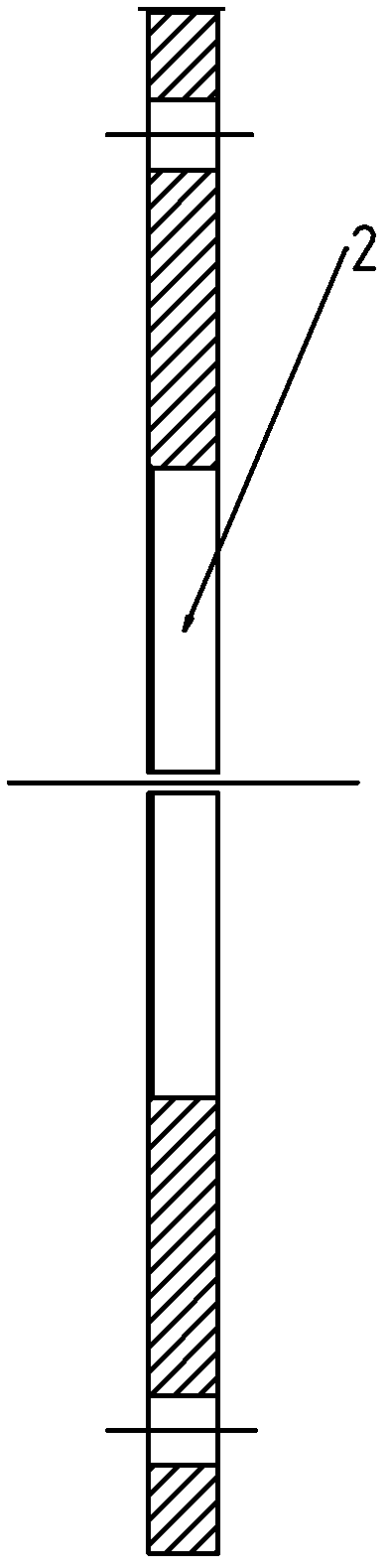

[0036] attached figure 1 Shown is the cold-rolled flying shear synchronous connection shaft device implemented according to the present invention, which is fixed between the frames on both sides of the cold-rolled flying shear; it mainly includes the first section shaft 1, the pad 2, the pad connecting plate 3, the first Flange 5, second flange 7, second segment shaft 8, third flange 9, fourth flange 10, third segment shaft 11, positioning pin 15 and other components.

[0037] The first shaft 1 is connected to the first flange 5 through the first key 12; the second shaft 8 is connected to the second flange 7 and the third flange 9 through the second key 13 and the third key 14 respectively, of course the first The second-section shaft 8 can also be connected as a whole with the second flange 7 and the third fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com