Testing device for relationship between pre-tightening force and torque for threaded fastening connection

A technology of tightening connection and test test, which is applied to measure the direction of torque/torsion force during tightening, which can solve problems such as assembly simulation, and achieve the effects of enhanced applicability, ease of manufacture, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

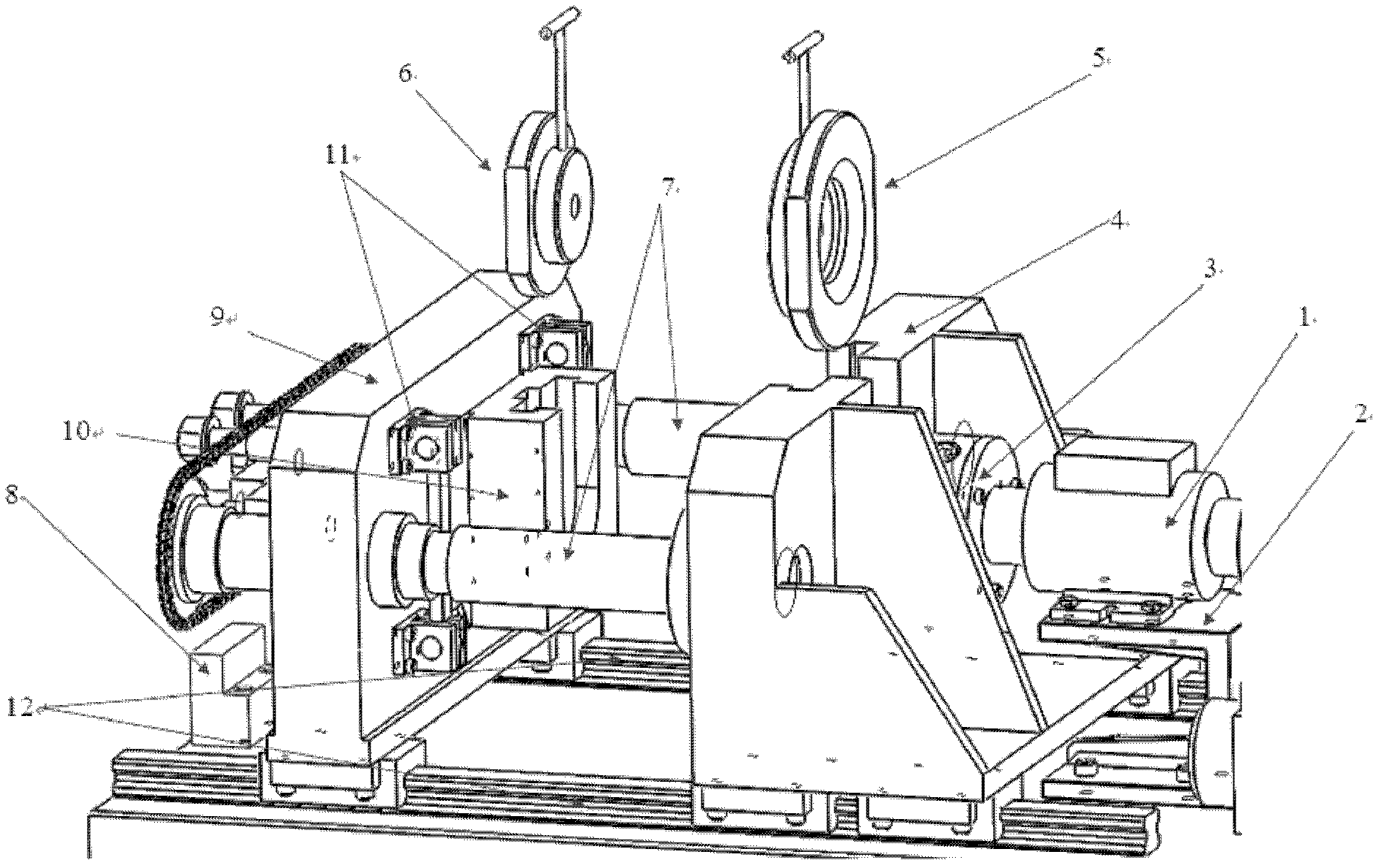

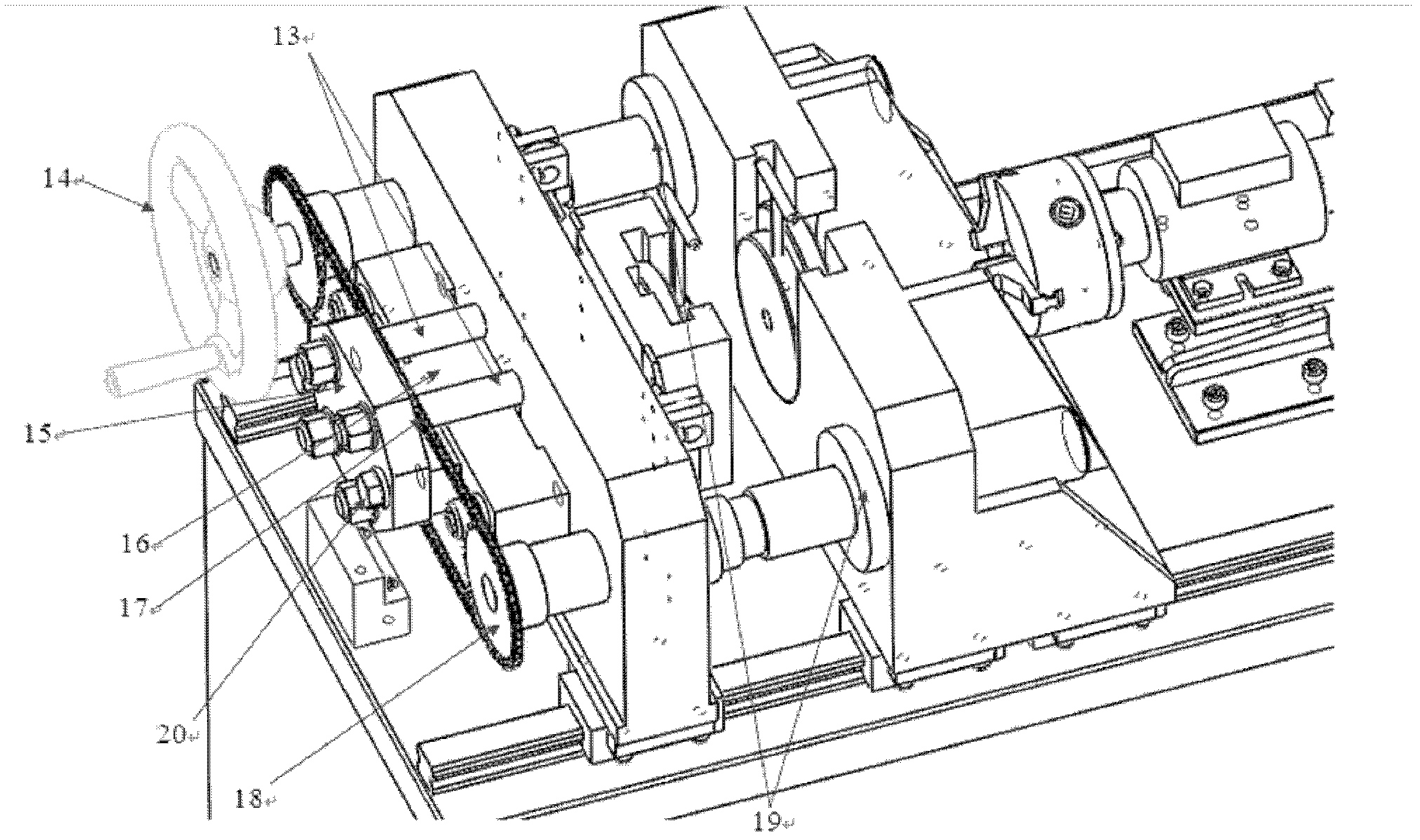

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0041] The design idea of the present invention is

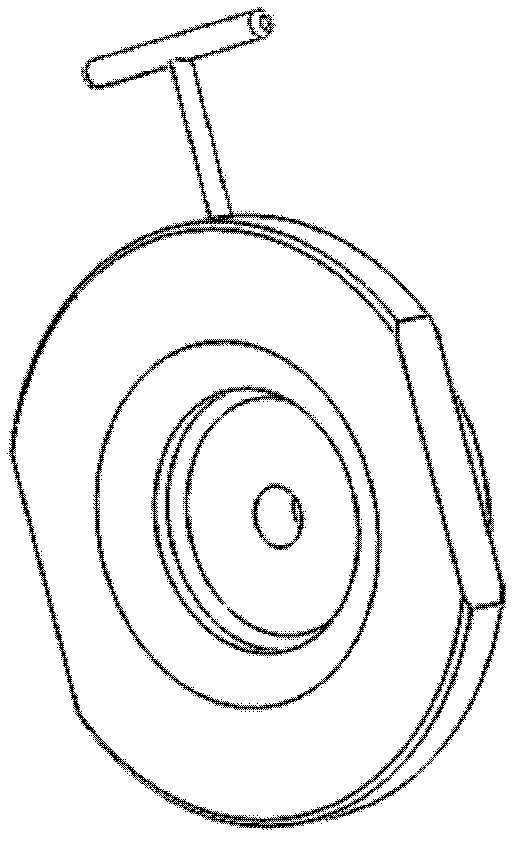

[0042] (1) Design the simulation structure of threaded fastening connection assembly

[0043] a. During actual assembly, the threaded fastener is to connect and fix two independent connected parts. The present invention adopts a split structure and designs two storage tables for placing fixtures for simulating connected parts.

[0044] b. The two storage tables are connected by screws, which is convenient for adjusting the position between the storage tables, so as to meet the experimental simulation requirements of different bolt lengths and thicknesses of the connected parts.

[0045] c. Two storage tables are placed on smooth guide rails for easy movement and torque loading.

[0046] d. Design fixtures for threaded fastening connections.

[0047] (2) Design the force value transmission structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com