Rubber dynamic friction wear detection device

A detection device and dynamic friction technology, which is applied to measurement devices, mechanical devices, instruments, etc., to achieve the effects of simple and easy detection technology, high detection accuracy, convenient monitoring and control, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

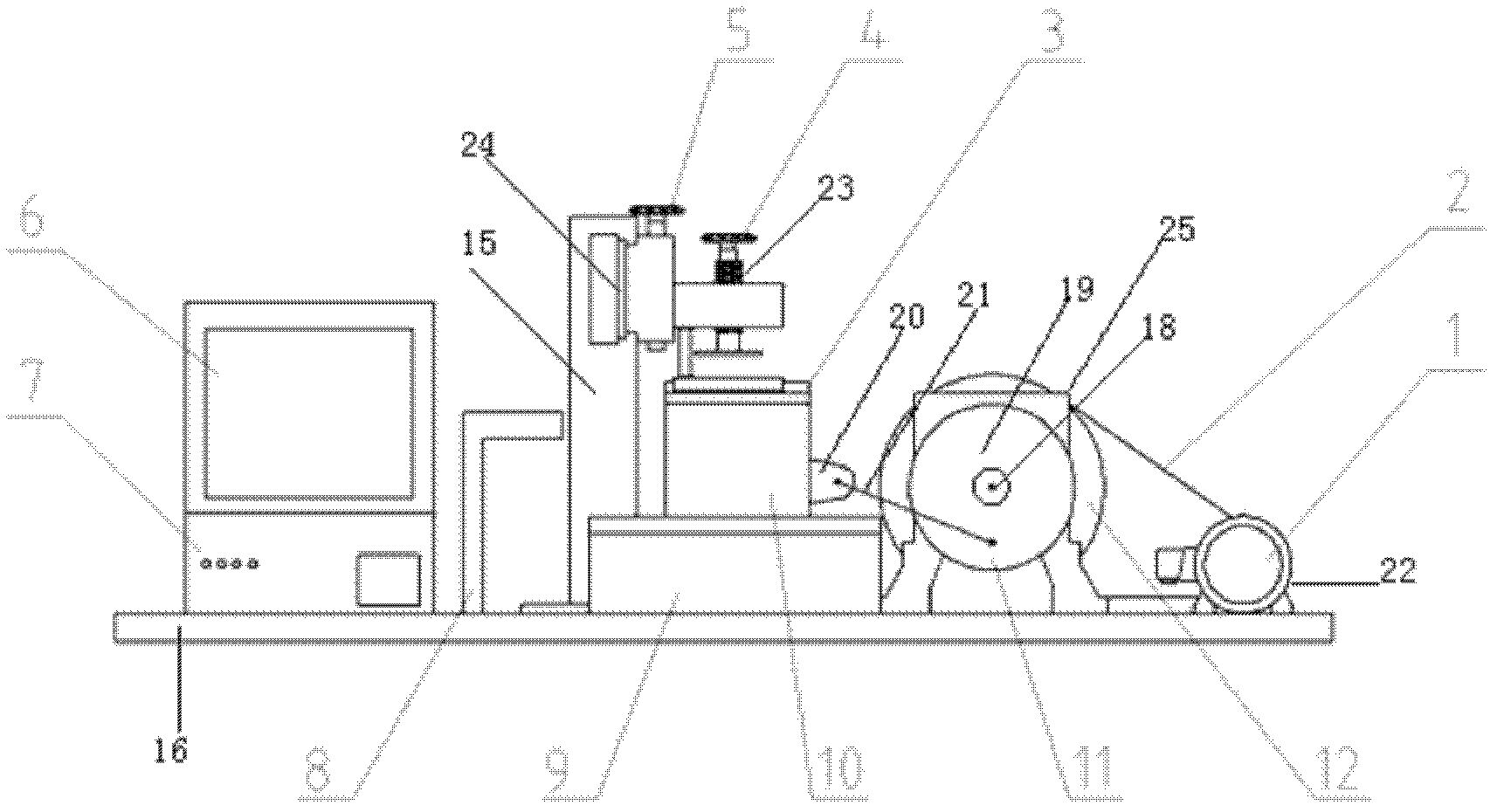

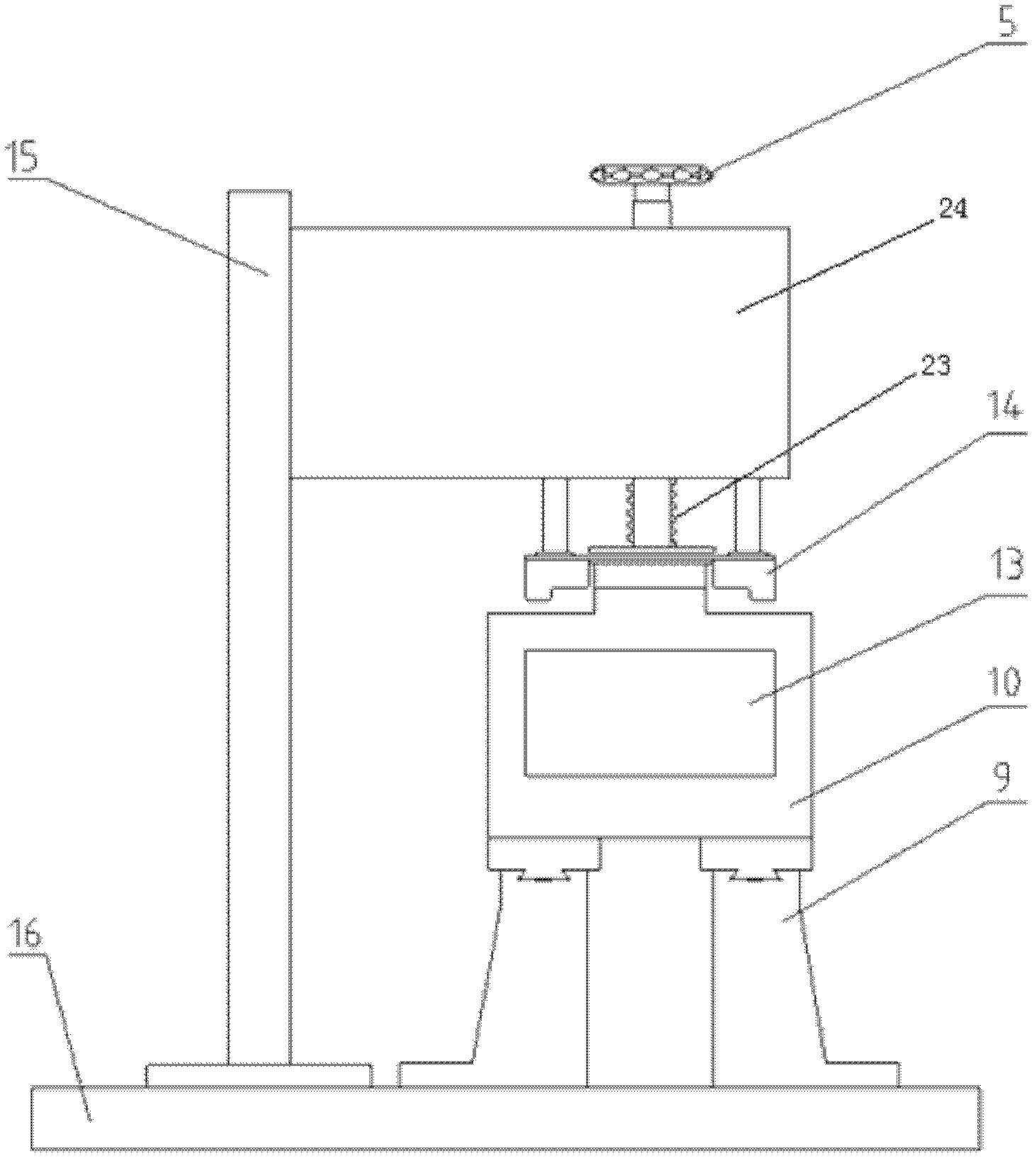

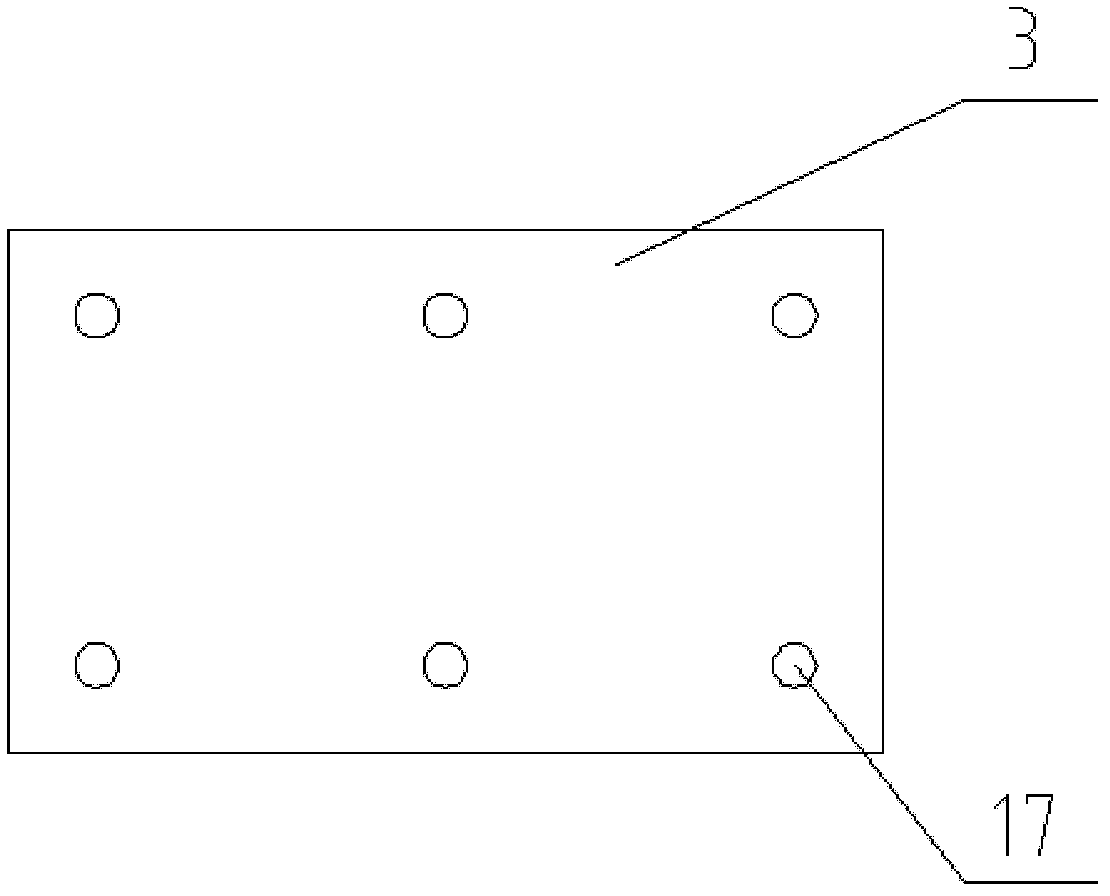

[0016] The main structure of this embodiment includes a motor 1, a belt 2, a friction model 3, a force application handle 4, a displacement control handle 5, a display 6, a controller 7, a wear measurement device 8, a guide rail 9, a sliding detection platform 10, and an eccentric wheel 11 , driven pulley 12, temperature control device 13, sample clamping device 14, support plate 15, base 16, data collector 17, main shaft 18, bearing 19, driving pulley 22, connecting rod 21, sliding body 20, Lead screw 23, load adjustment device 24 and shaft end support plate 25; motor 1 is connected with driving pulley 22 and forms belt type transmission structure by driving pulley 22 through belt 2 and driven pulley 12; driven pulley 12 The plug-in connection is fixed on the main shaft 18 and forms the middle transmission part with the rolling bearings 19 fixed on both ends of the main shaft 18 at the same time. On the left side of the main shaft 18, a shaft end support plate 25 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com