Method for detecting chloride ion impurities in high concentration chromic anhydride solution

A detection method and high-concentration technology, applied in the direction of material electrochemical variables, etc., can solve the problems of inability to detect harmful impurity chloride ions, fail to meet the requirements of rapid detection, etc., and achieve the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The detection method of chloride ion impurity in high-concentration chromic anhydride solution of the present invention may further comprise the steps:

[0010] Take 50ml of the high-concentration chromic anhydride solution containing various impurities and put it in a 150ml titration cup. Under the uniform stirring of the automatic potentiometric titrator, add 25% sodium hydroxide adjustment solution dropwise to the chromic anhydride solution to adjust the concentration to be detected. After the pH value of the solution reaches 4.5-5, the maximum jump point detected by the automatic potentiometric titrator is set as the titration end point, the automatic potentiometric titrator is turned on, and the silver nitrate standard solution with a concentration of 0.0400mol / L is used for titration; Reagent blank titration;

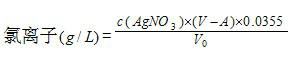

[0011] Calculate the chloride ion content:

[0012]

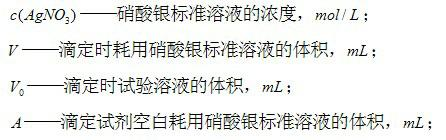

[0013] In the formula:

[0014]

[0015] 0.0355——with 1.00mL silver nitrate standard solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com