Method and device for measuring smoldering rate of cigarette paper

A measuring device, technology of cigarette paper, applied in the direction of using a device for measuring the time required to move a certain distance, a radio wave measuring system, re-radiation of electromagnetic waves, etc., can solve non-conformity, paper sample shaking, on-off time support rod To avoid problems such as too fast movement, to achieve the effect of avoiding shaking and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

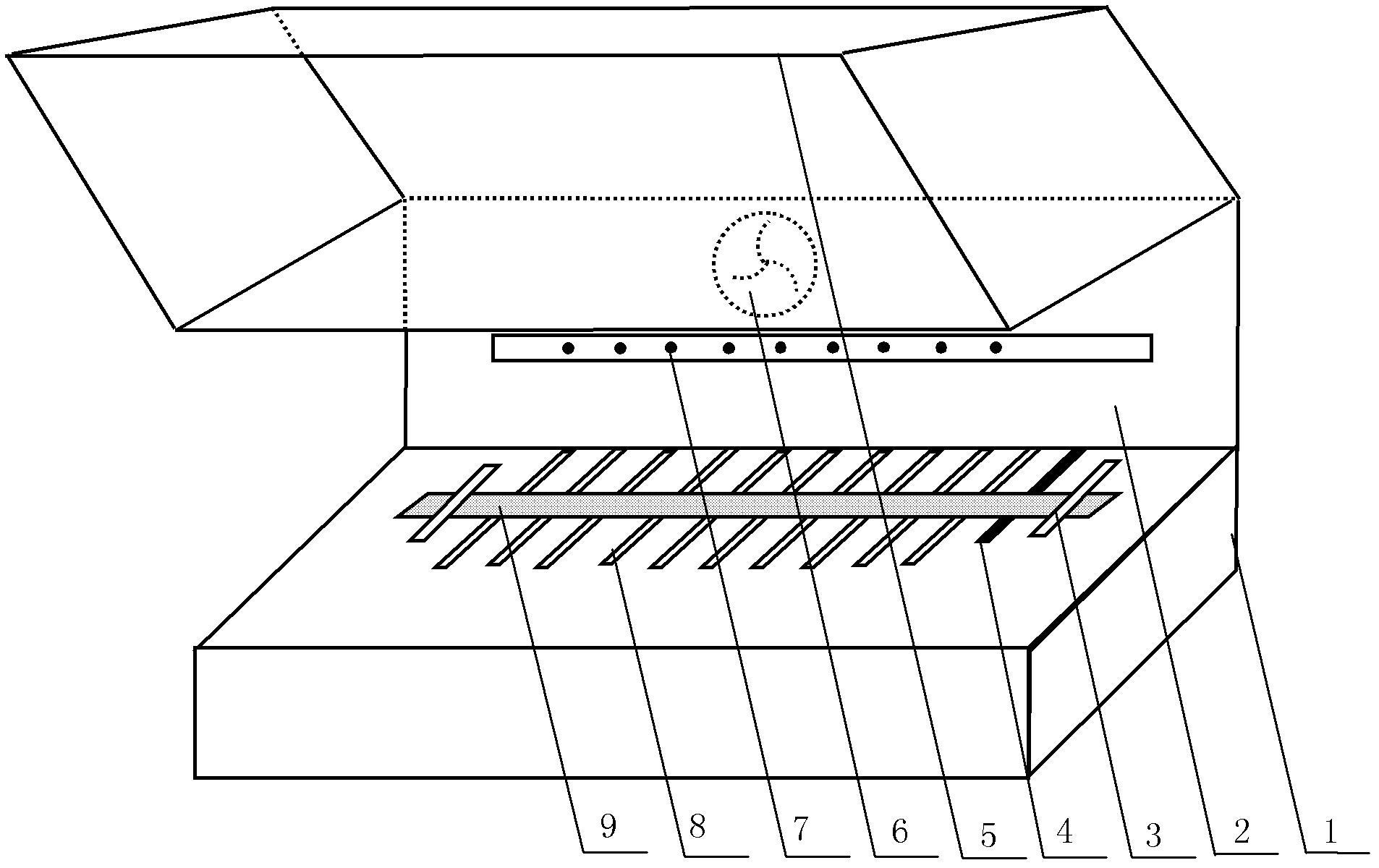

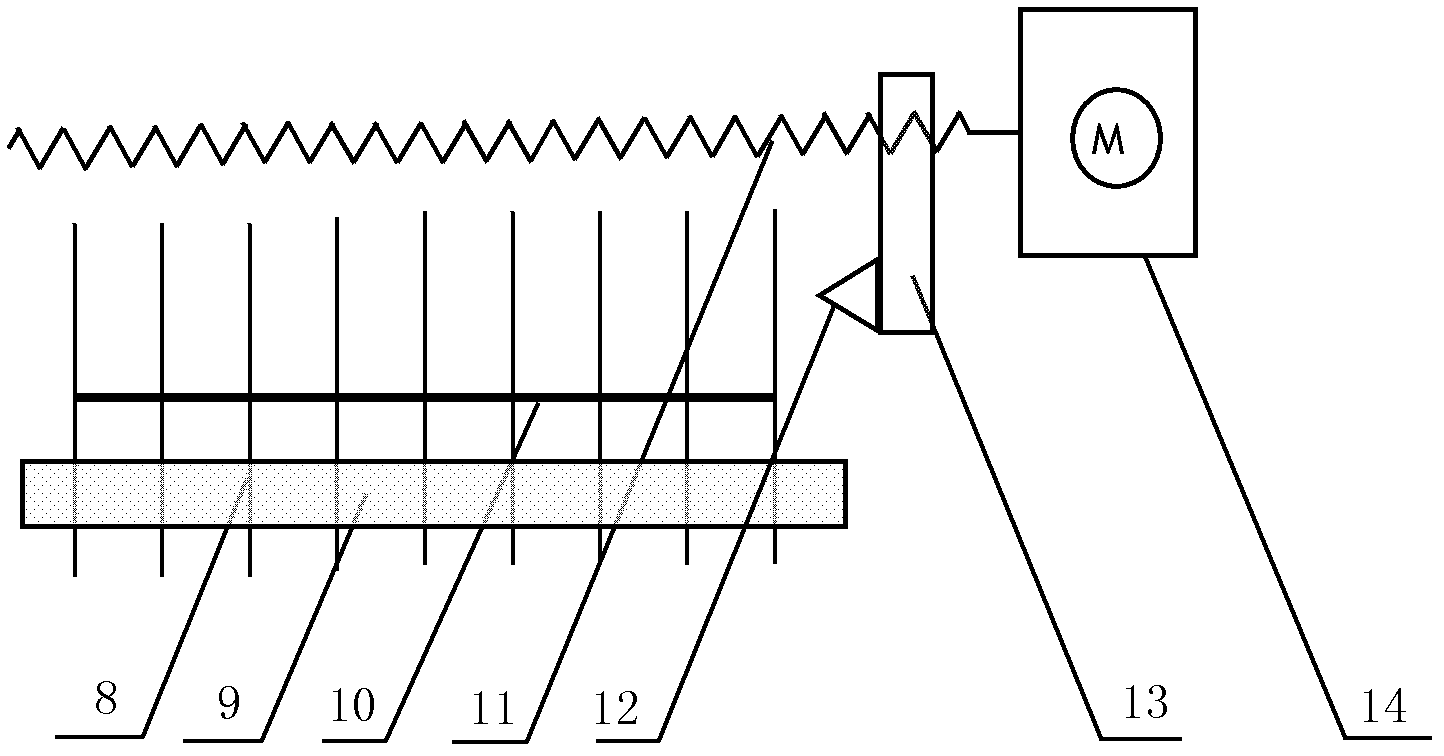

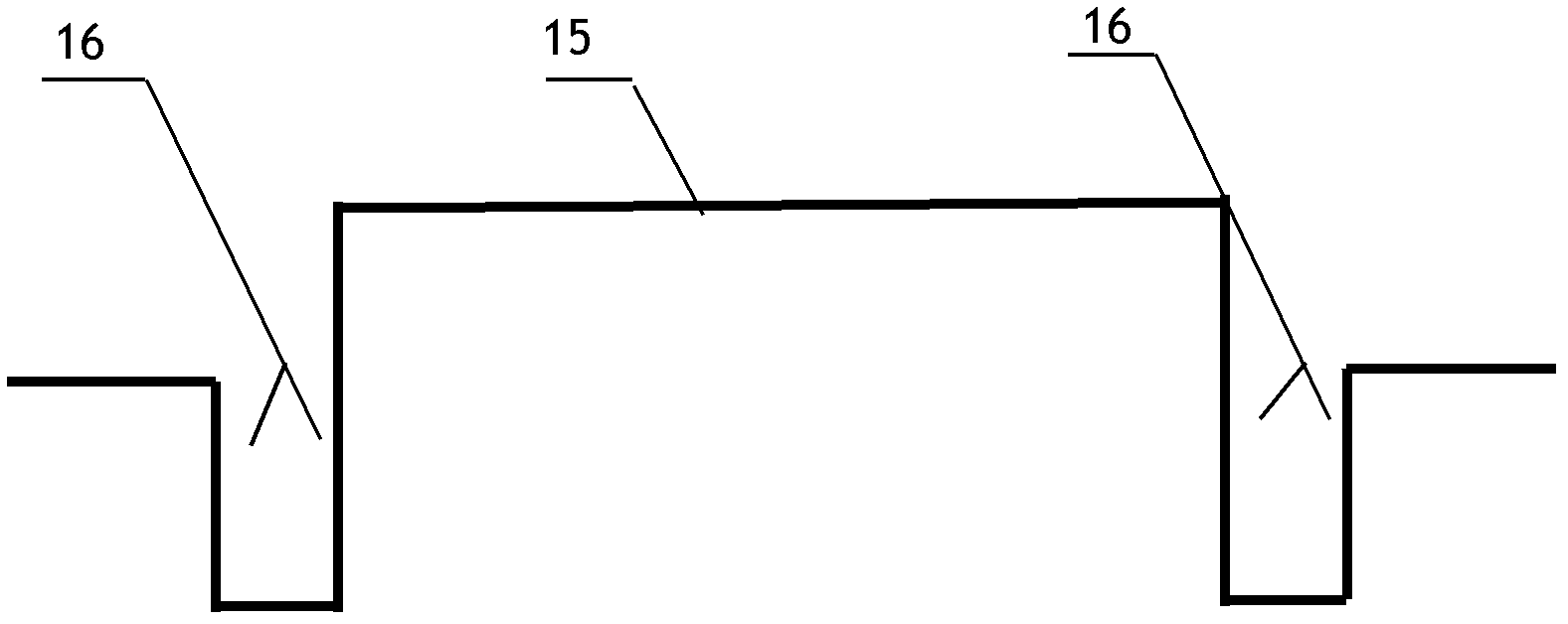

[0031] Referring to the accompanying drawings, the measuring device for the smoldering rate of cigarette paper includes a base 1 and a combustion chamber cover 5. The material of the base 1 is metal, and a baffle 2 is installed at the rear end of the base 1. The combustion chamber cover 5 is hinged on the The upper edge of the plate 2, the top of the baffle plate 2 is provided with a smoke exhaust device 6, and the bottom of the smoke exhaust device 6 is provided with an infrared detection device 7, and the infrared detection device 7 includes a row of uniformly arranged several infrared probes. The base 1 is provided with a support rod 8 corresponding to the infrared probe of the infrared detection device 7, and each support rod 8 is provided with a support shaft 10 perpendicular to the support rod 8, and the center of each support rod 8 is horizontally hinged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com