Circuitry built-in test device based on boundary scanning mechanism

A test device and boundary scan technology, which is applied in electronic circuit testing, measuring devices, measuring electricity, etc., can solve the problems of weak self-test and diagnosis ability, lack of in-machine self-test means, and many levels of structural composition, and achieves a high level of improvement. The effect of testing diagnostic capabilities, improving overall testing capabilities, and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

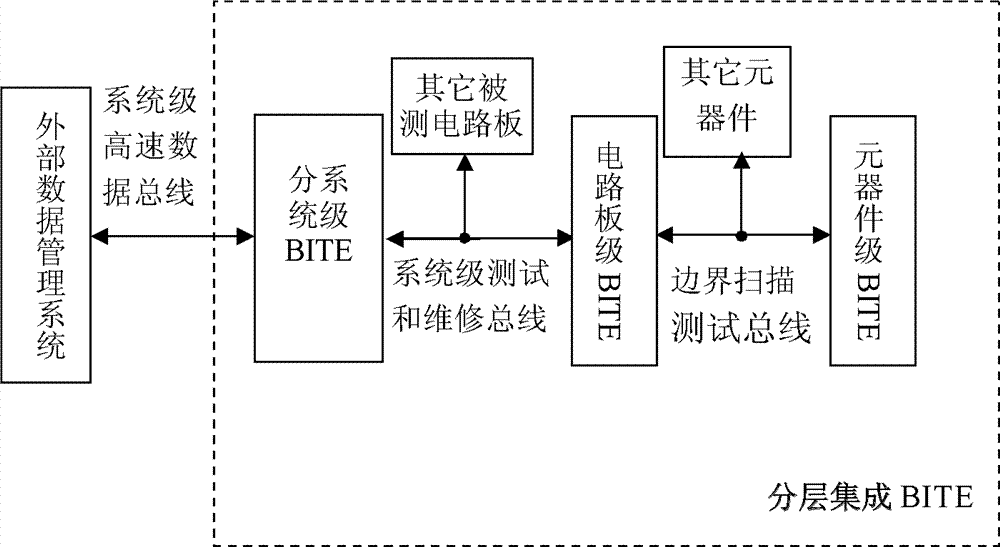

[0020] The present invention adopts a hierarchically integrated BITE structure, which is composed of subsystem-level BITE, circuit board-level BITE, and component-level BITE. Such as figure 1 As shown, among them, the subsystem-level BITE is interconnected with the external data management system through the system-level high-speed data bus (such as the 1553B bus), and the next level is connected with the circuit board-level BITE and the circuit board level through the system-level test and maintenance bus (such as the CAN bus). Other circuit boards under test in other subsystems are interconnected, and the circuit board-level BITE is interconnected with the component-level BITE and other components in the circuit board through the boundary scan test bus to the next level.

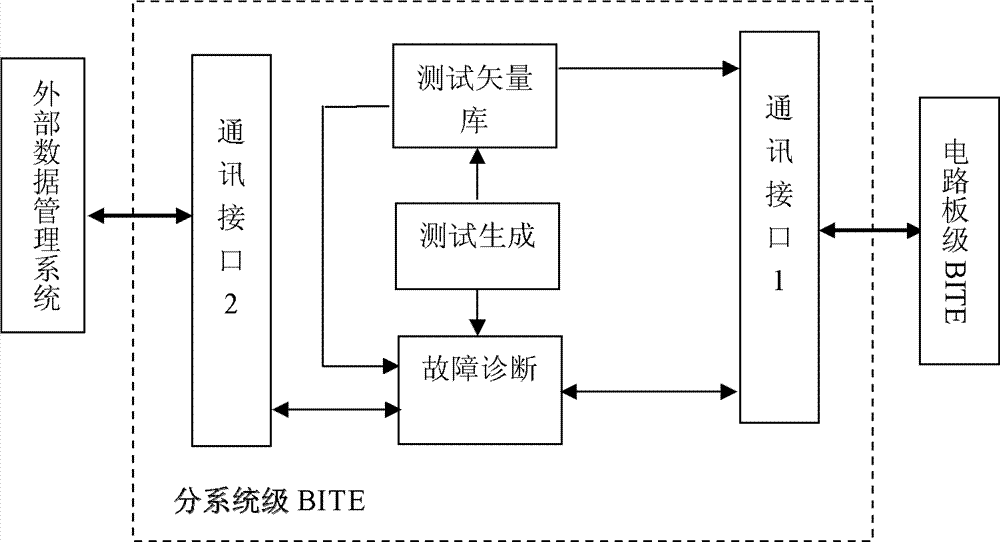

[0021] Sub-system level BITE consists of five units including test generation, test vector library, fault diagnosis, communication interface 1, and communication interface 2, such as figure 2 shown. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com