Control method of integral saturation resistance in auxiliary machine failure load reduction process

A control method and auxiliary machine failure technology, applied in the field of anti-integral saturation control, can solve the problems of slow reverse adjustment time, unfavorable adjustment, and system oscillation, and achieve the effect of reducing load, facilitating adjustment, and maintaining safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

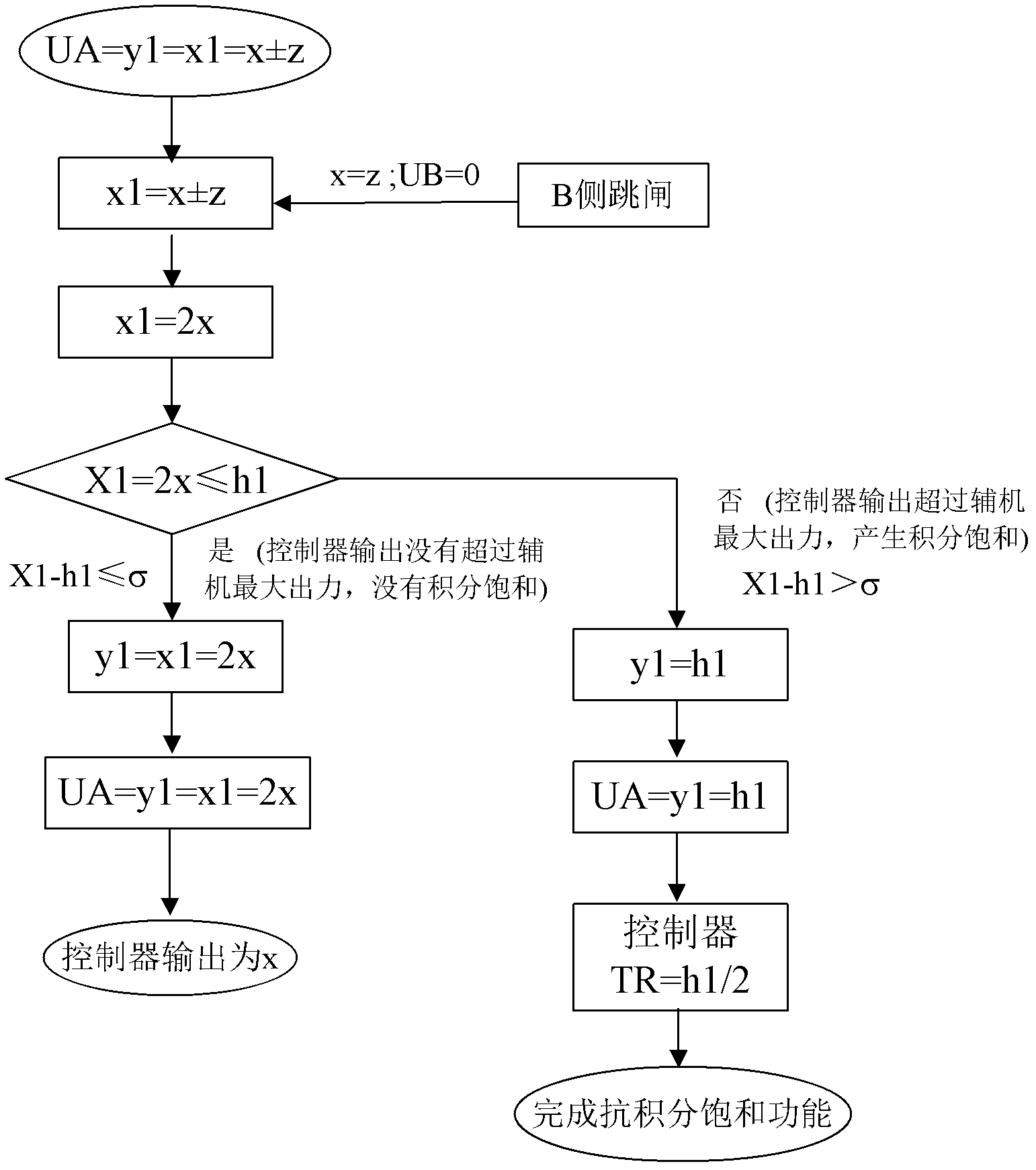

[0023] In an actual digital PID control system, the change of the control quantity is limited within a certain effective travel range due to the constraints of the physical and mechanical characteristics of the actuator or the actuator (such as the valve opening).

[0024] u min ≤U≤U max

[0025] When the output control quantity is within this range, the system is normally adjusted. Once the control quantity exceeds this limit range, the action of the actuator is no longer the calculation quantity of the control system. When the control quantity is reversed, it will take a long time for the control quantity to leave the saturation area. Therefore, It causes a large overshoot of the system, which is not good for system adjustment, and integral saturation increases the time for system adjustment.

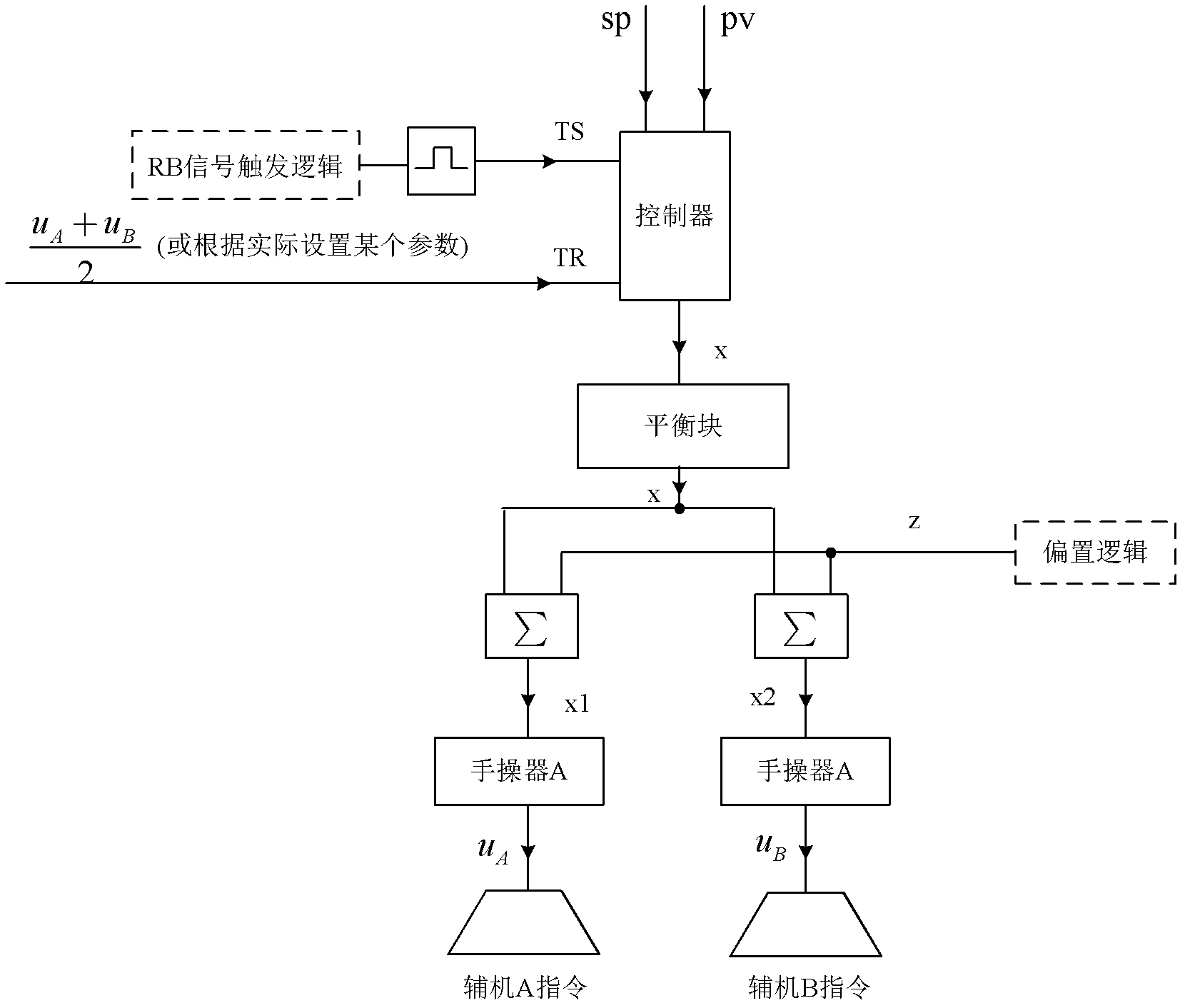

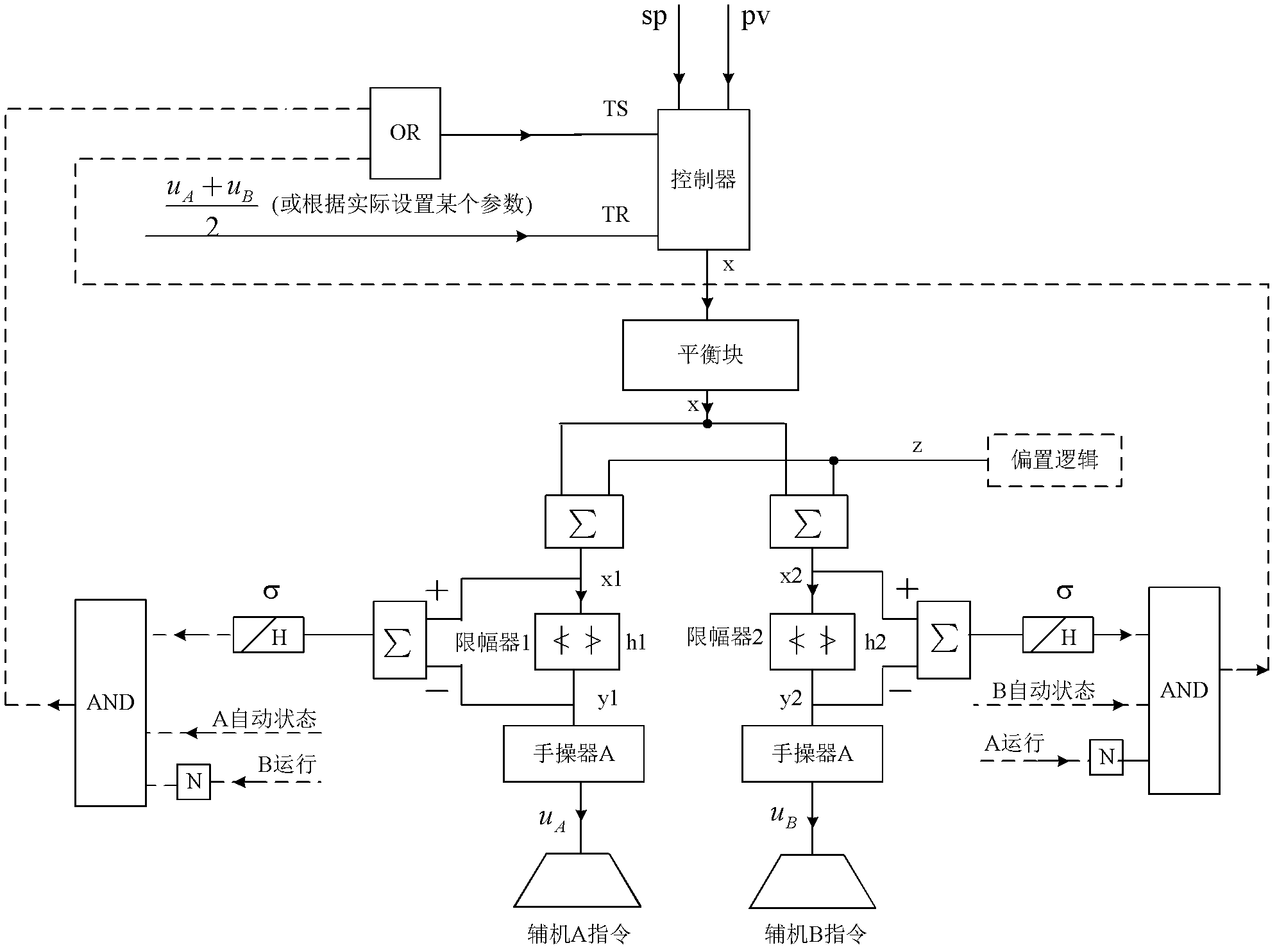

[0026] Such as figure 2 Shown is the control scheme ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com