Automatic crude oil blending controlling method

A crude oil blending technology, which is applied in the flow control of electric devices, etc., can solve the problems of inaccurate proportioning, high operating intensity, and poor safety, and achieve the effects of improving production efficiency, ensuring safety, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

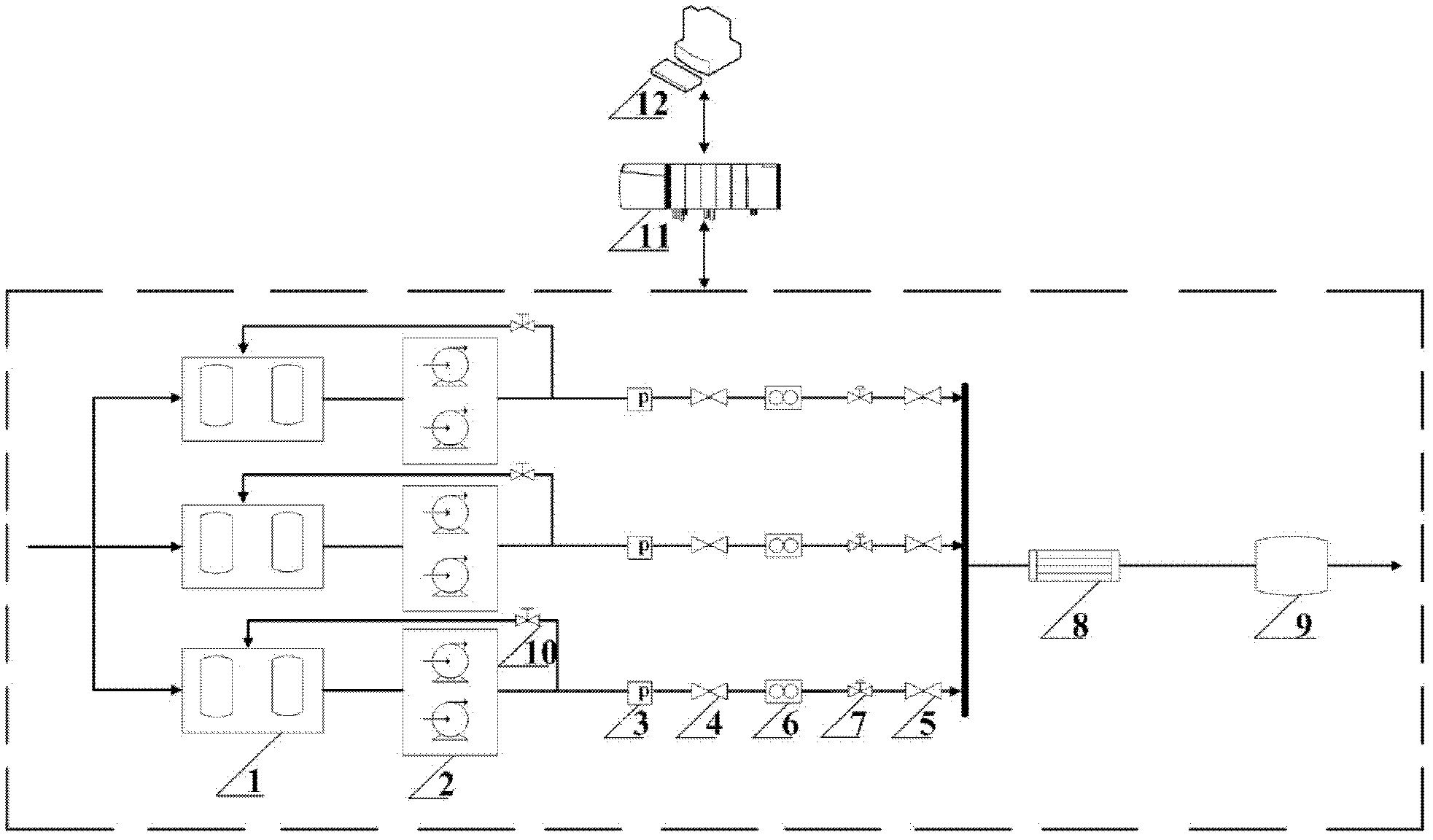

[0037] Taking the actual implementation of the present invention in a refining and chemical enterprise as an example, the detailed implementation and specific operation process are given below. The enterprise has 3 blending lines and 6 crude oil component tanks. This embodiment is implemented on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

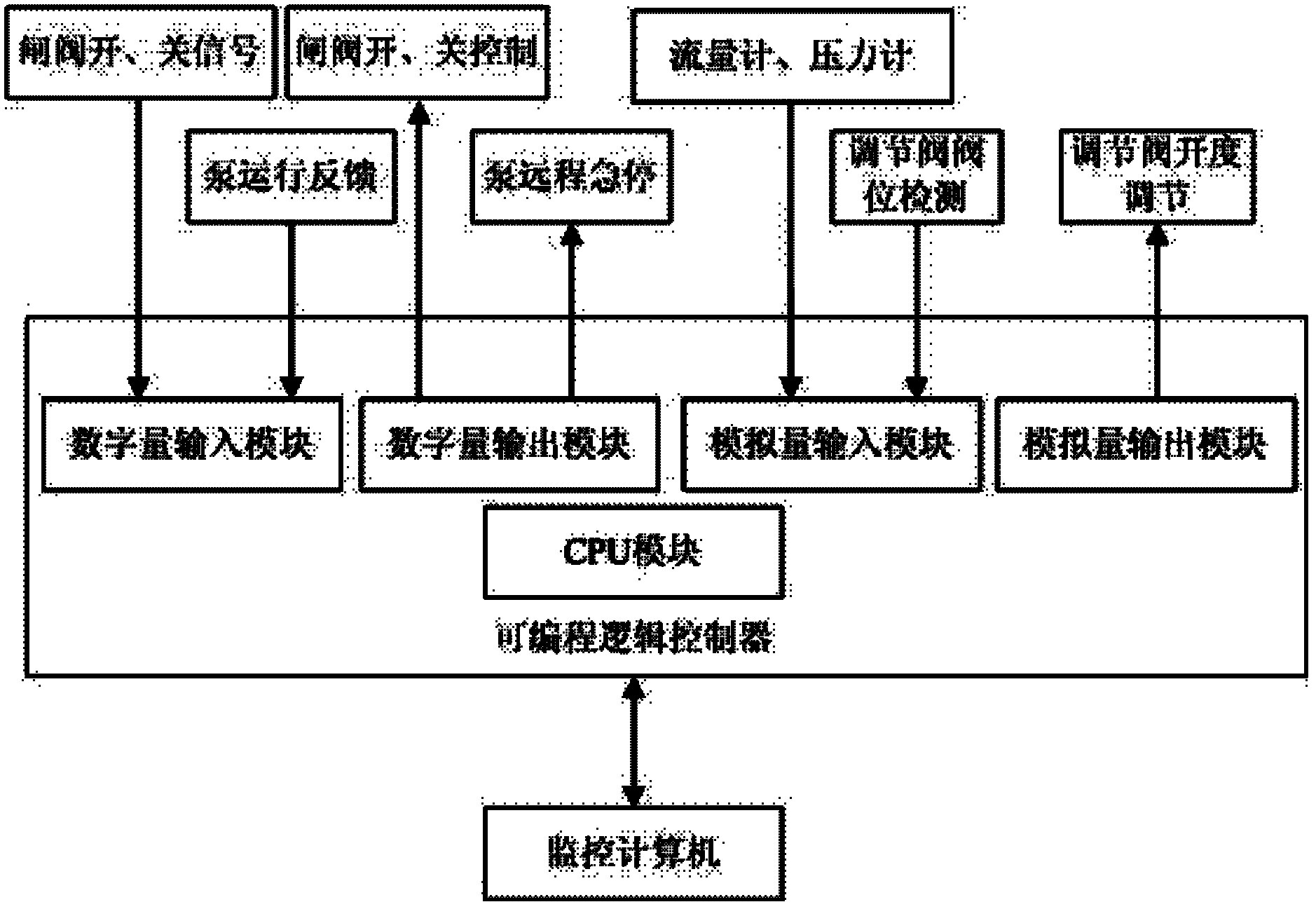

[0038] like figure 2 As shown, the system includes a blending component tank 1, a blending pump 2, a pressure gauge 3, a cut-off valve 4 before the flow meter, a cut-off valve 5 after the flow meter, a flow meter 6, a regulating valve 7, a static mixer 8, a regulating valve A buffer tank 9, a return valve 10, a programmable controller 11 and a monitoring computer 12.

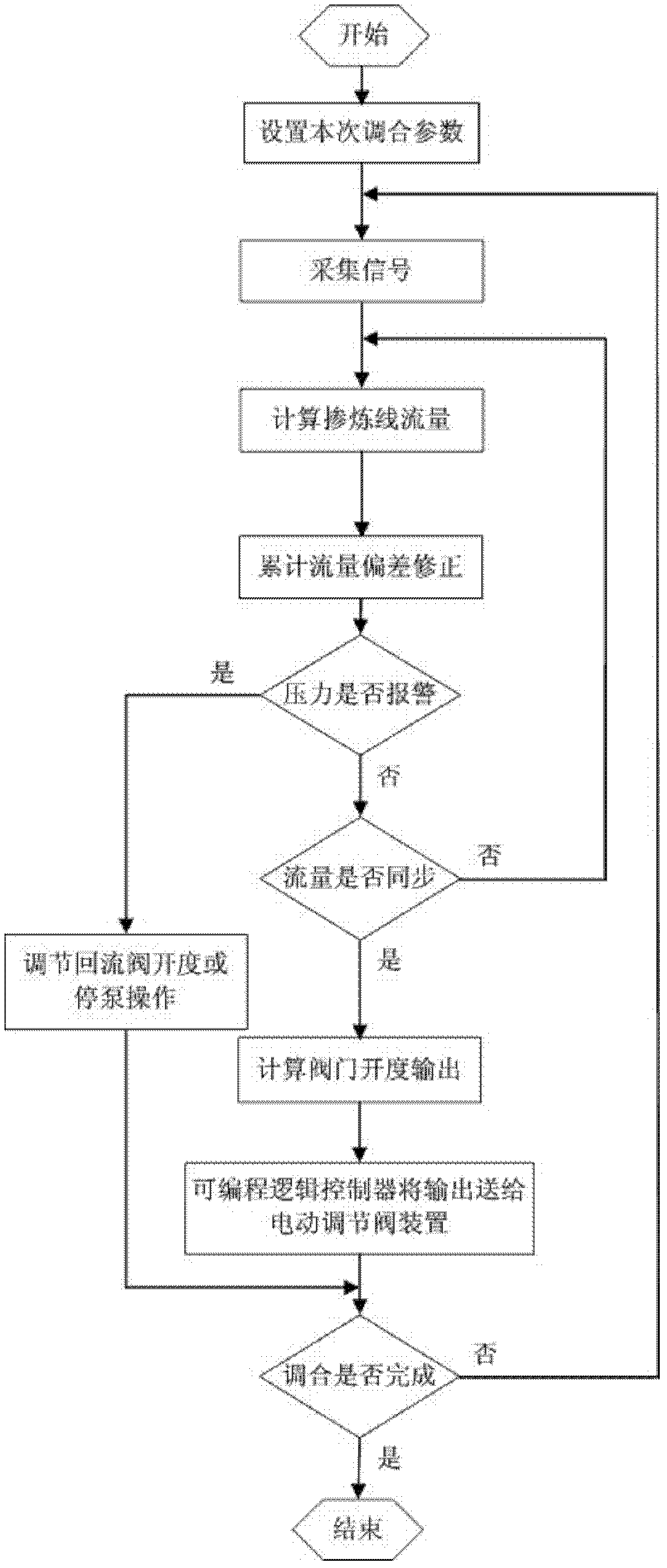

[0039] like figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com