Cemented carbide and process for producing same

A technology of cemented carbide and binder, which is applied in the field of preparing the cemented carbide and can solve the problems of microstructure defects and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

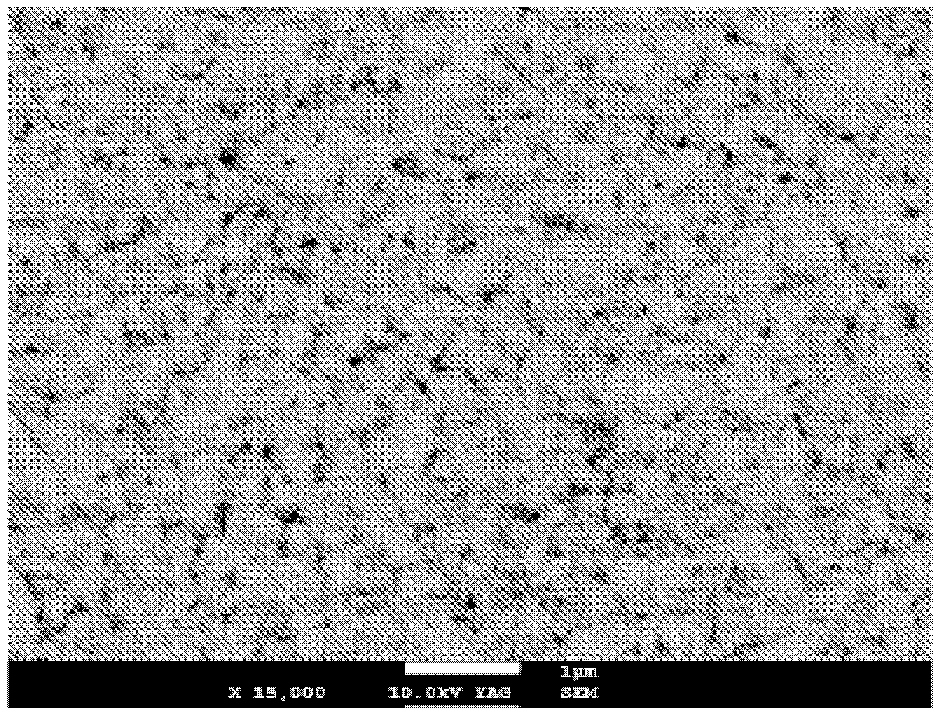

[0050] The specific surface area (BET) measured according to the ASTM 3663 standard is 4.0m 2 / g and tungsten carbide powder with a carbon content of 6.14wt.% (Germany, derived from H.C.Starck TM 4NPO) with about 10wt.% cobalt powder, 0.8wt.% Cr 3 C 2 , 0.3wt.%VC, 0.5wt.%Mo 2 C. Blending of 0.1wt.% TaC and 0.1wt.% ZrC, wherein the average grain size of Co grains in the cobalt powder is about 1 micron. Blends were prepared by ball milling the powders together in a milling medium consisting of hexane and 2 wt.% paraffin wax at a powder-to-ball ratio of 1 :6 for 24 hrs. After the blend was dried, samples of various sizes, including those used for testing transverse rupture strength (TRS) according to ISO 3327-1982 and ASTM B611 -85 standard test samples for abrasion resistance. The green bodies were then sintered at 1370° C. for 20 min, including a 10 min vacuum sintering stage and a 10 min high isostatic pressing (HIP) sintering stage under argon atmosphere and 50 bar press...

Embodiment 2

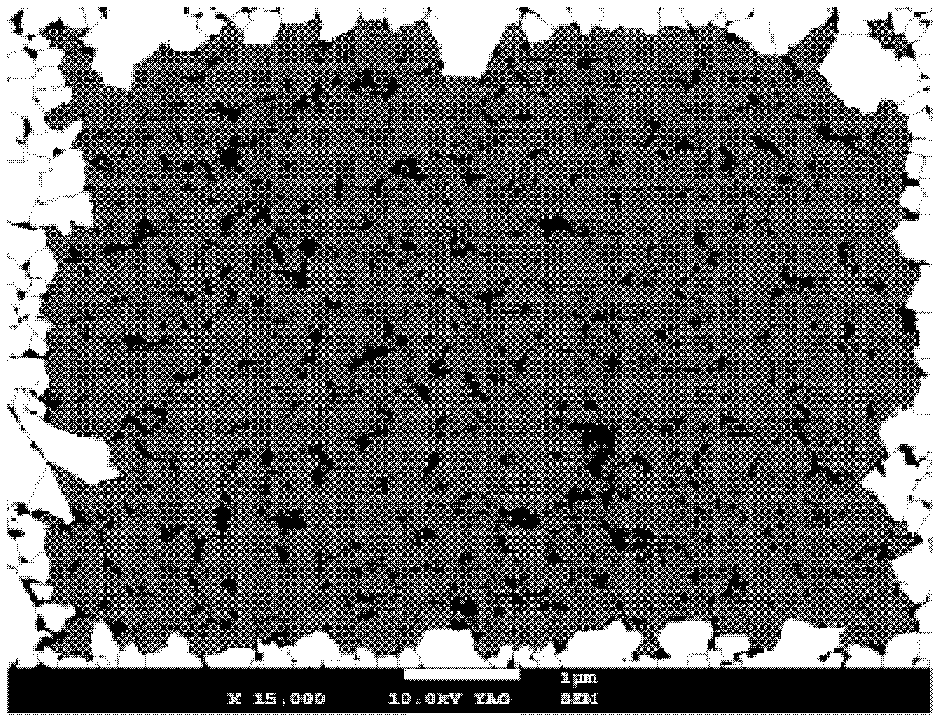

[0053] The specific surface area (BET) measured according to the ASTM 3663 standard is 4.0m 2 / g and tungsten carbide powder with a carbon content of 6.14wt.% (Germany, derived from H.C.Starck TM 4NPO) with about 5wt.% cobalt powder, 0.4wt.% Cr 3 C 2 , 0.15wt.%VC, 0.25wt.%Mo 2 C. Blending of 0.05wt.% TaC and 0.05wt.% ZrC, wherein the average grain size of Co grains in the cobalt powder is about 1 micron. Blends were prepared by ball milling the powders together for 24 hrs in a milling medium consisting of hexane and 2 wt. % paraffin wax at a powder to ball ratio of 1 :6. After the blend was dried, samples of various sizes, including those used for testing transverse rupture strength (TRS) according to ISO 3327-1982 and ASTM B611 -85 standard test samples for abrasion resistance. The green body was then sintered at 1390° C. for 20 min, including a 10 min vacuum sintering stage and a 10 min high isostatic pressing (HIP) sintering stage under argon atmosphere and 50 bar press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com