Zipper assembly equipment and zipper machine with same

A technology for equipment and chain splicing, applied in the application, sliding fastener components, fasteners and other directions, can solve the problems of a large range of motion of the pendulum rod, many guide wheel groups, and large space occupied by the chain assembling equipment, so as to reduce the space occupation. efficiency, saving space, and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

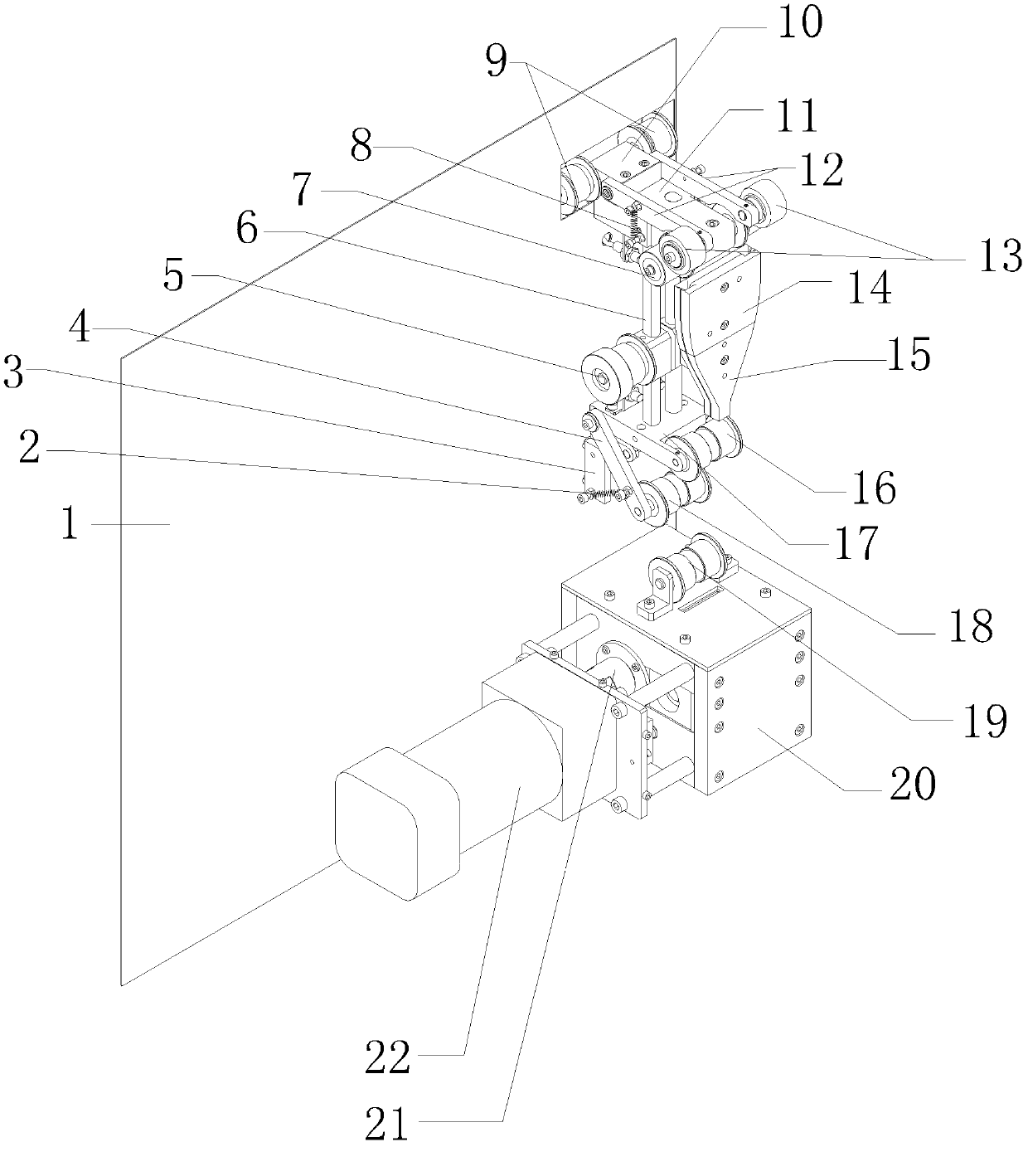

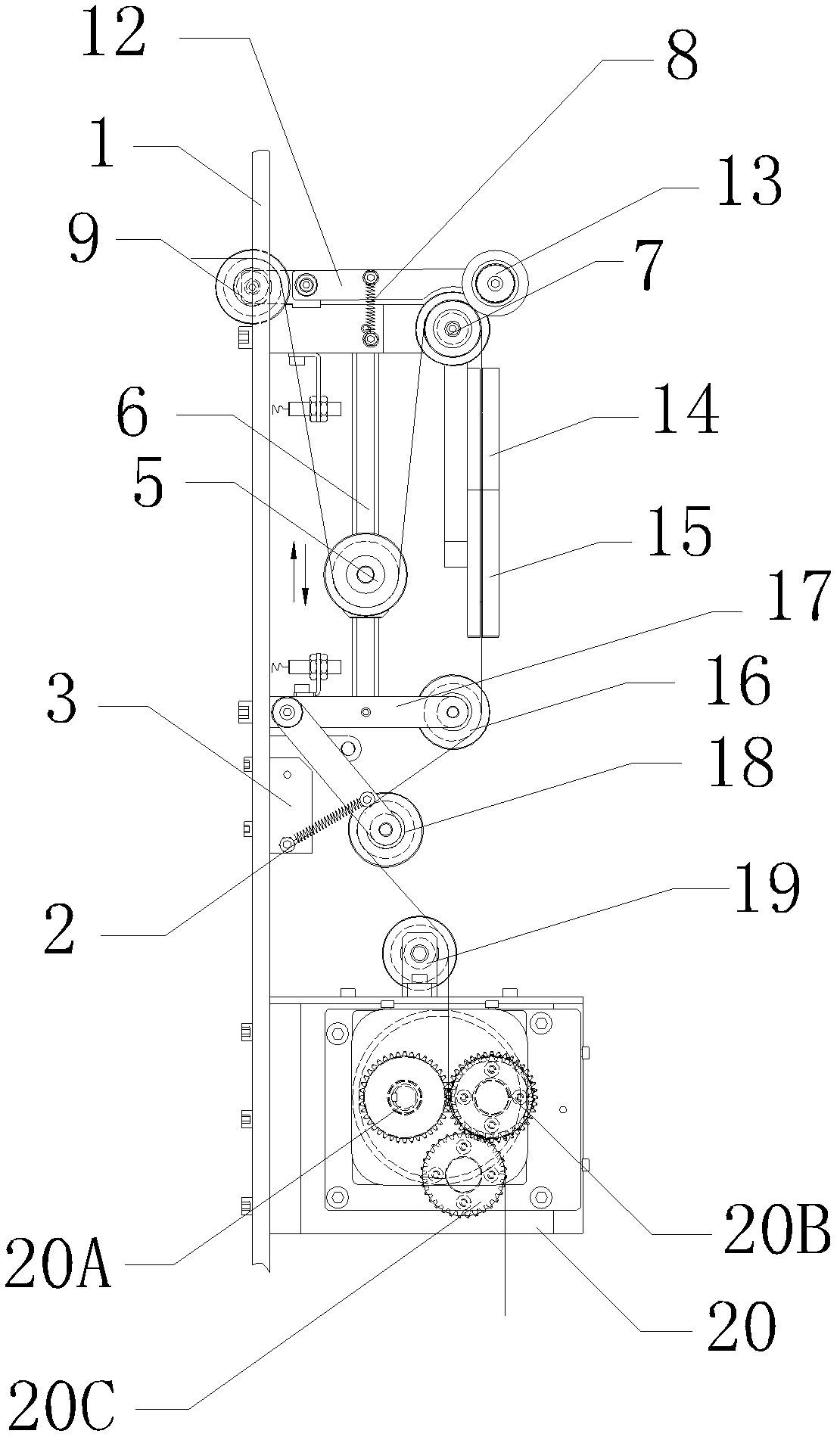

[0058] The first embodiment of the present invention relates to a chain spelling device, such as figure 1 shown, including:

[0059] The detection mechanism that outputs the control signal according to the speed of the chain out of the zipper and the speed of the spliced chain;

[0060] The splicing mechanism for splicing the zipper tape;

[0061] Drag the towing mechanism of the zipper belt, and the towing mechanism drags the zipper belt through the detection mechanism and the splicing mechanism in sequence;

[0062] It also includes a control module for controlling the towing of the towing mechanism according to the control signal output by the detection mechanism;

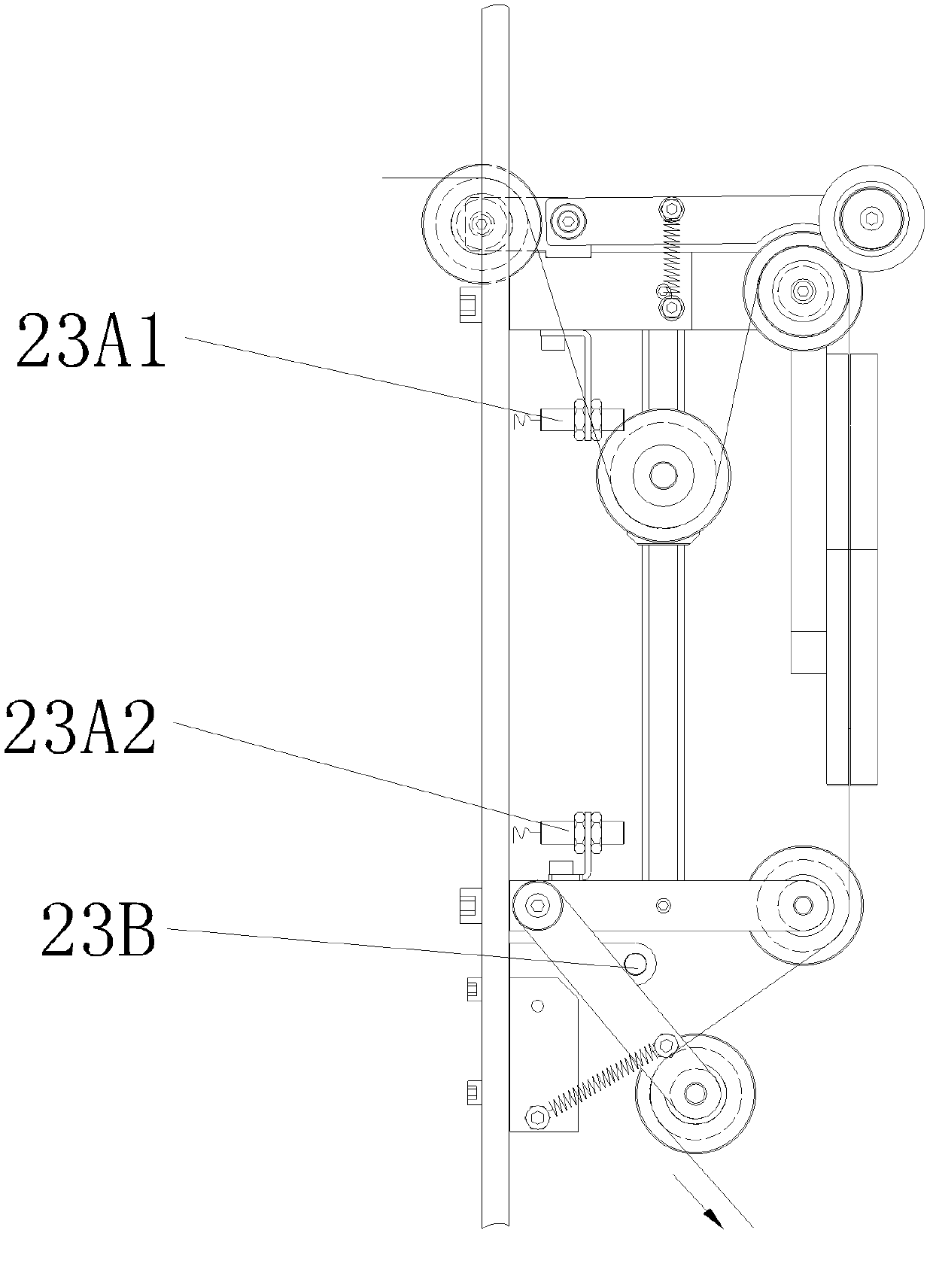

[0063] Described detection mechanism comprises first supporting base 11, second supporting base 17, guide rod 6 and detection element, and first supporting base 11 and second supporting base 17 are vertically arranged on mounting surface 1, and guiding rod 6 is formed by the first supporting base. 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com