Double-introduction-layer tower expanding cavity type separator

A technology of expansion cavity and separator, which is applied in the direction of the device whose axial direction can be reversed, the swirl device, etc., can solve the problems of increased cost and trouble, and achieve a large processing capacity, easy manufacture, and a wide range of high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the drawings and embodiments, but it is not limited to this embodiment.

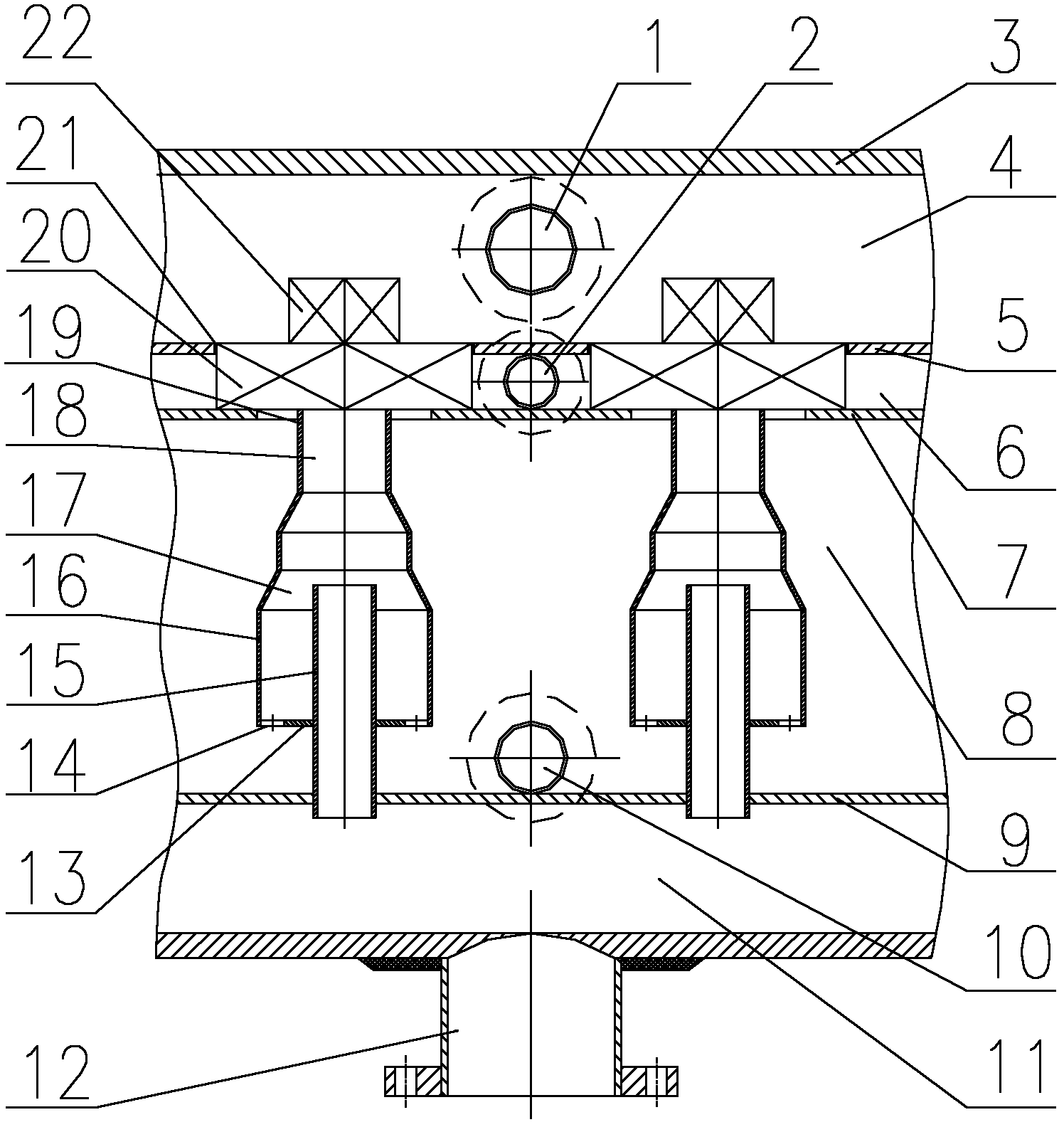

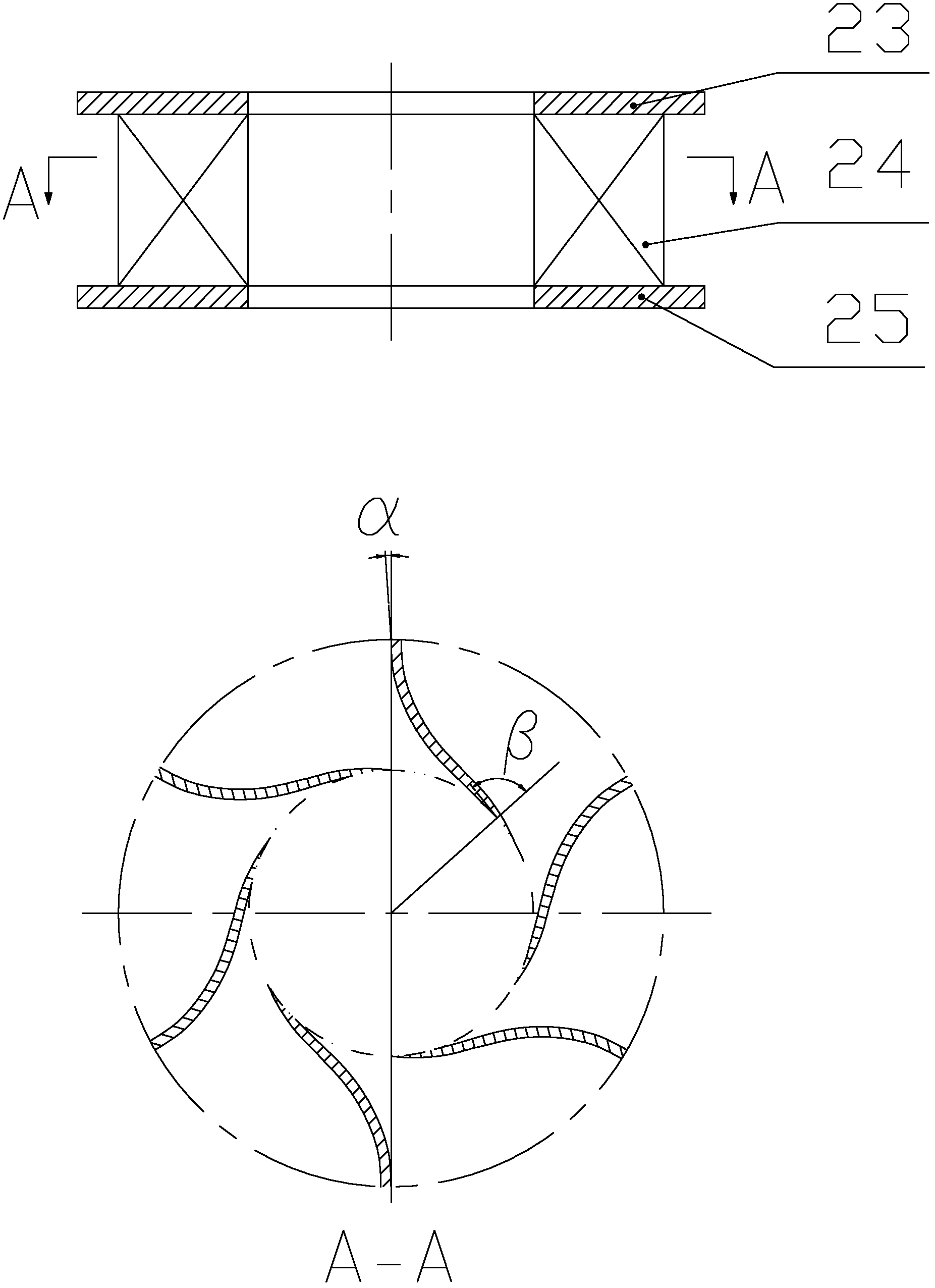

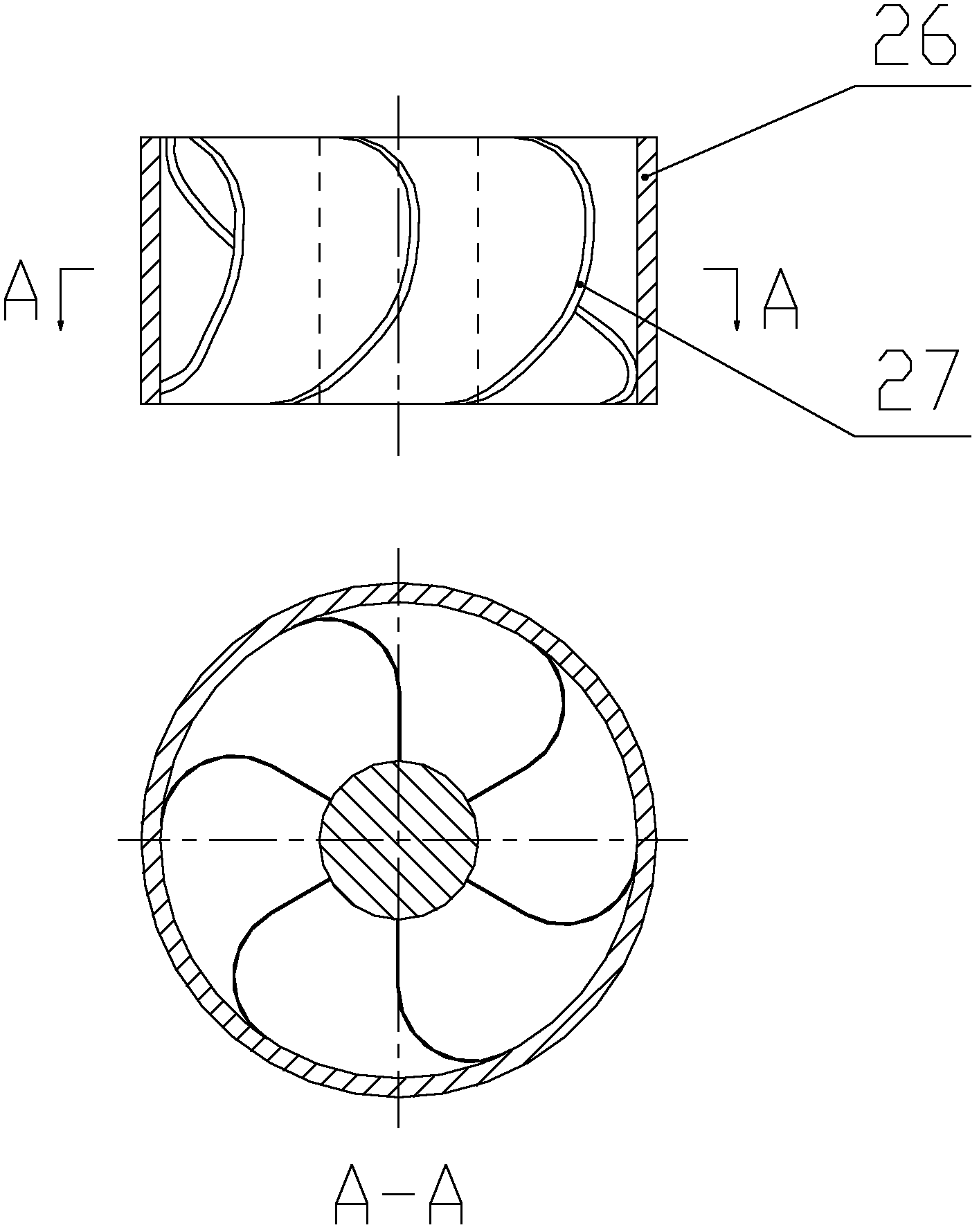

[0039] Such as figure 1 As shown, the double-introduction layer tower expansion chamber separator of the present invention is surrounded by a shell 3, an upper partition 5, a middle partition 7, a lower partition 9, a large flow inlet 1, an upper partition and the upper part of the housing. Flow buffer chamber 4, small flow inlet 2, small flow buffer chamber surrounded by upper and middle partitions and the upper part of the shell 6, heavy medium confluence chamber 8 surrounded by middle and lower partitions and the lower part of the shell , The heavy medium outlet 10, the light medium confluence chamber 11 enclosed by the lower partition and the lower part of the shell, the light medium outlet 12, and at least one cyclone sedimentation separation unit. Among them: each cyclone sedimentation separation unit is composed of its o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com