Pier thickness stamping process of separated pull ring and pier thickness stamping die

A technology for separating pull rings and stamping dies, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced wall thickness at the window of the separation pull ring, failure to meet the use strength requirements, and unusable clutch assembly, etc. Achieve the effects of increasing strength, strong practicability, and reducing deviations in shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below through specific examples. It should be noted that the following descriptions are only for explaining the present invention, and do not limit its content.

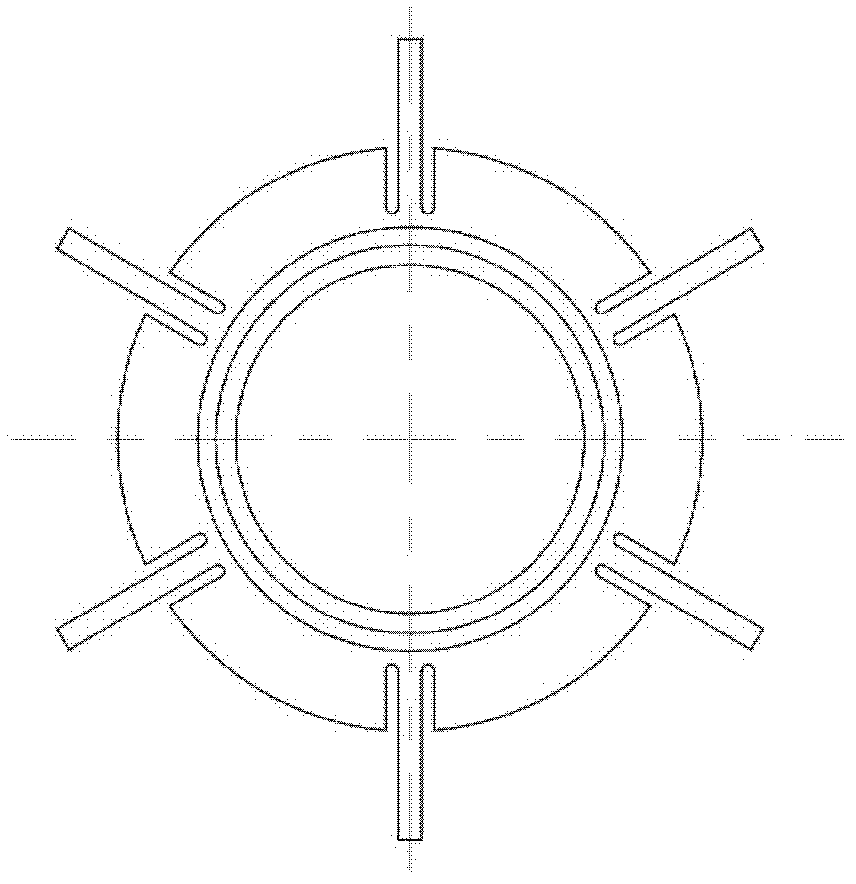

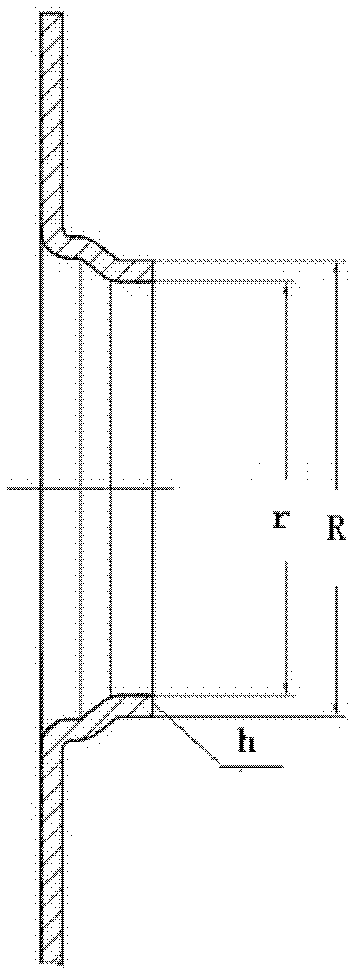

[0025] A pier thickness stamping process for separating the pull ring, such as figure 2 As shown, the wall thickness of the separated pull ring product is 4.5mm, and the inner hole size is 89mm. This process needs to be carried out after stretching and forming. The process is: after stamping and stretching the separation ring of the diaphragm clutch, it is subjected to a pier thickness trimming stamping process. The stamping process for trimming the pier thickness is:

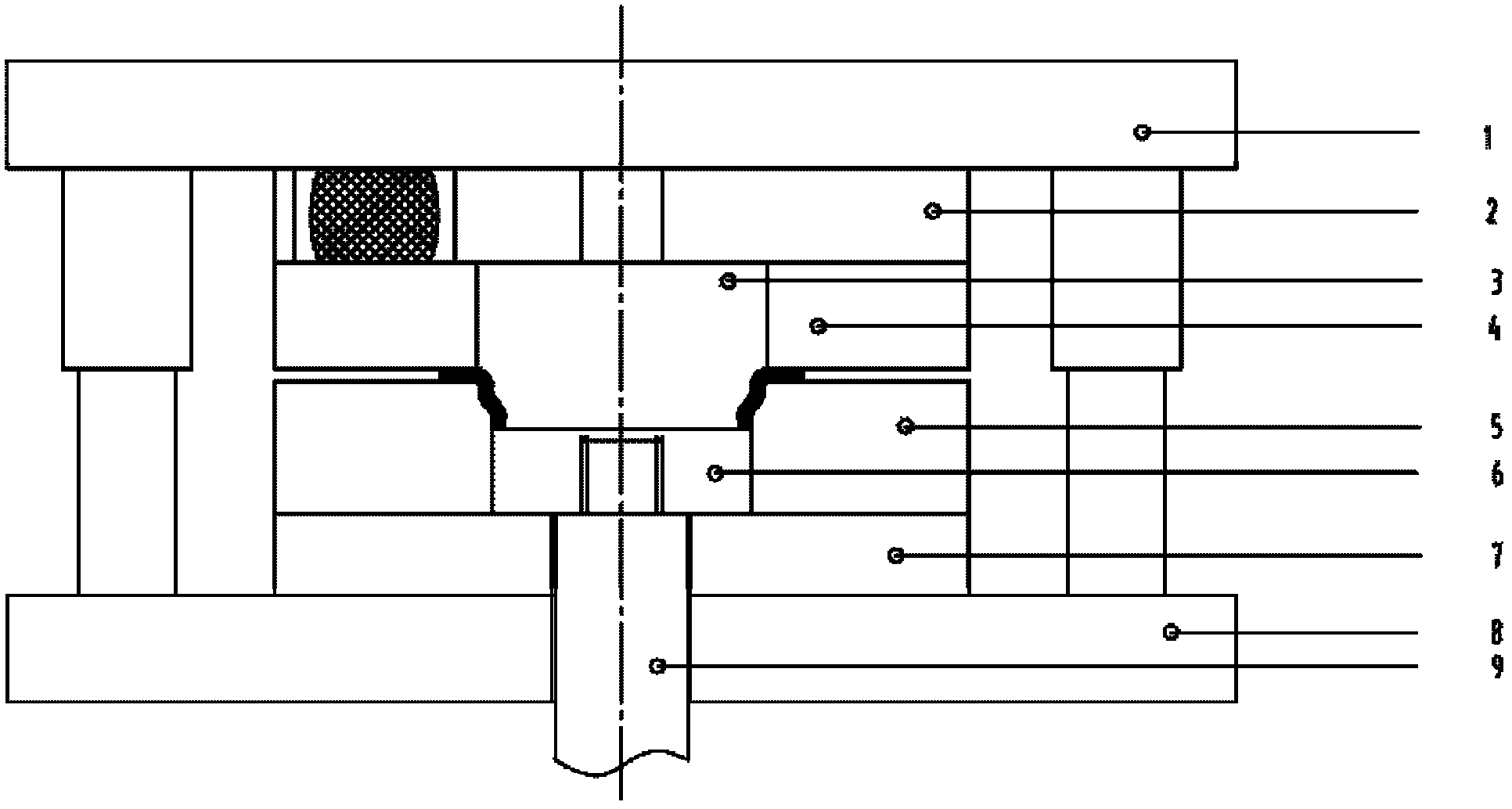

[0026] (1) Select the designed pier thickness trimming stamping die (such as figure 1 As shown): the mold includes an upper mold base, a lower mold base and a lower ejector rod. The ejector rod passes through the lower top seat and the lower backing plate to connect with the lower top plate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com