H-type finned tube welding machine-automatic tensioning system for welded steel tubes

A finned tube and welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low efficiency and low product positioning accuracy, achieve high safety, ensure dimensional consistency, The effect of simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawings:

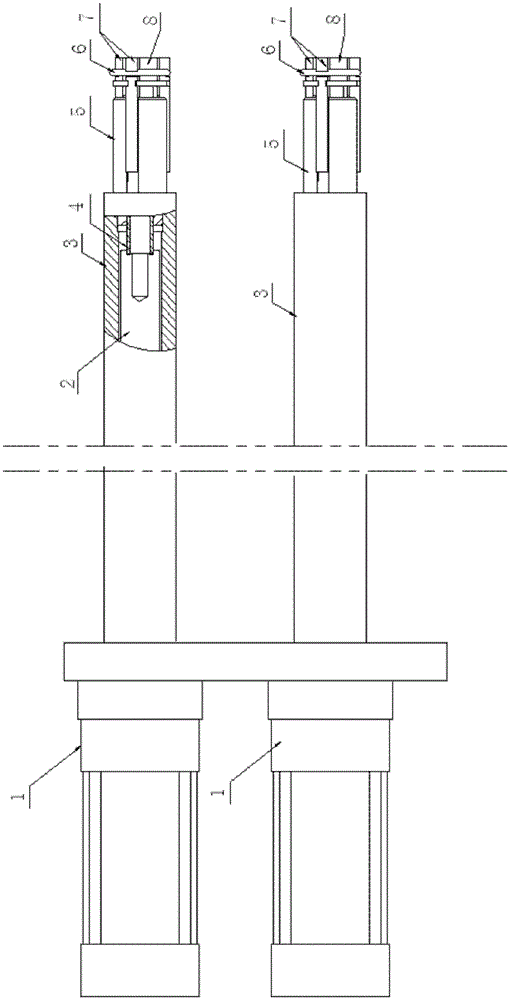

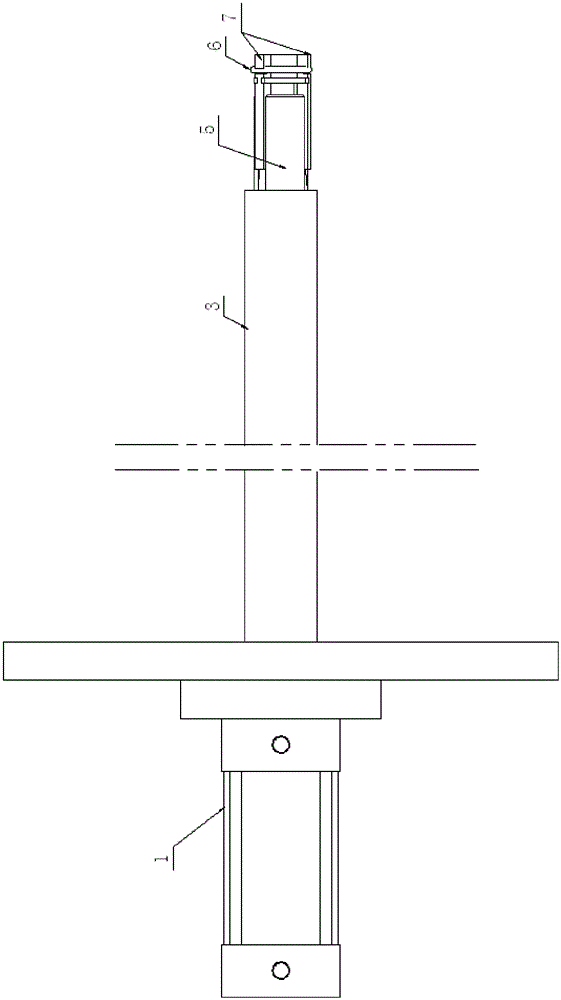

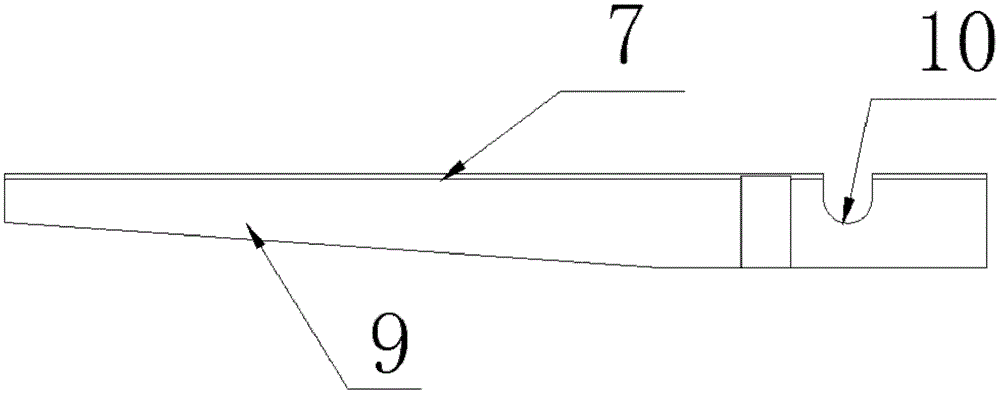

[0016] Such as Figures 1 to 4 , an H-type finned tube welding machine--automatic tensioning system for welded steel pipes, including cylinder 1, pull rod 2, pull rod outer sleeve 3, clamp shaft 4, clamp sleeve 5, spring 6, clamp slide 7 and clamp slide Block fixing seat 8, the piston of the cylinder 1 is connected to one end of the pull rod 2, the pull rod 2 is provided with a pull rod outer sleeve 3, the other end of the pull rod 2 is connected to the clamp shaft 4, the clamp shaft 4 is connected to the clamp slider fixing seat 8, and the clamp slider The fixed base 8 is movably connected with some clamp sliders 7 by spring 6, the clamp slider fixed base 8 is provided with a clamp bushing 5 which can move in a straight line and axial direction, and the clamp slider 7 cooperates with the clamp slider fixed base 8 to tighten.

[0017] The clamp slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com