Ejecting mechanism

A roof and component technology, applied in the field of upper mechanism for processing machinery, can solve the problems of large power consumption, time and labor consumption, and increase of production cost, and achieve the effect of flexible adjustment, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

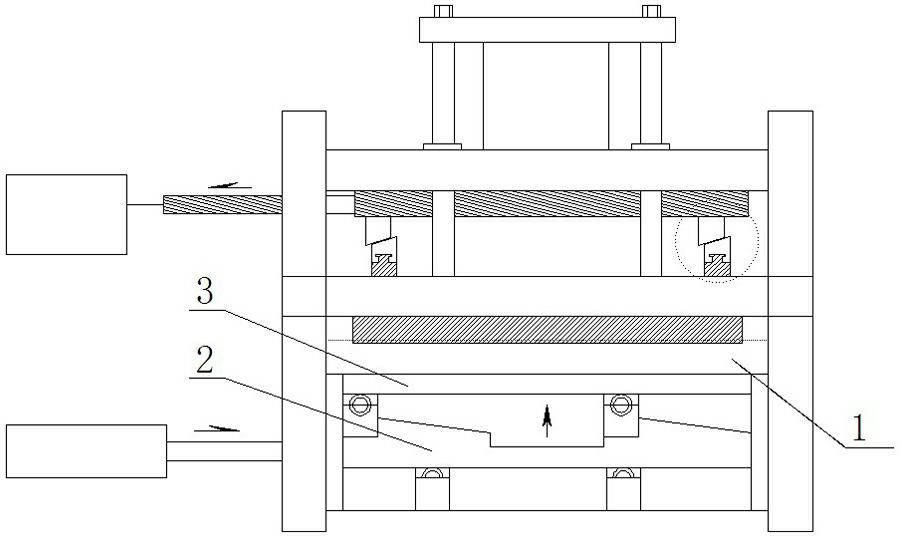

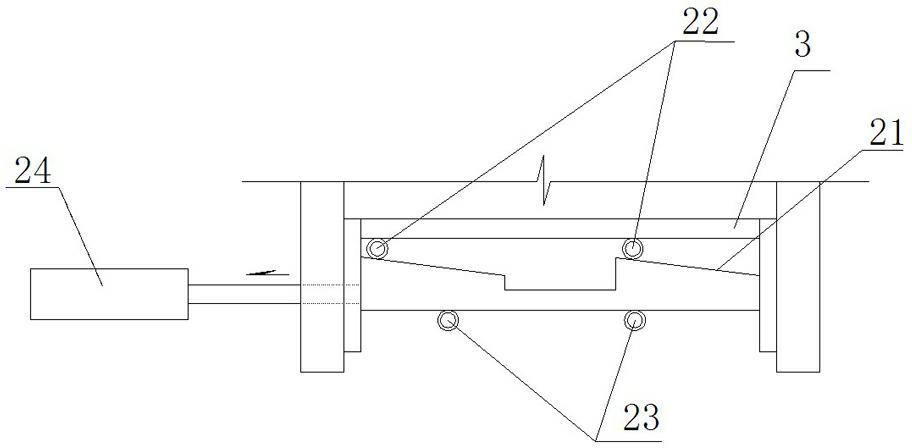

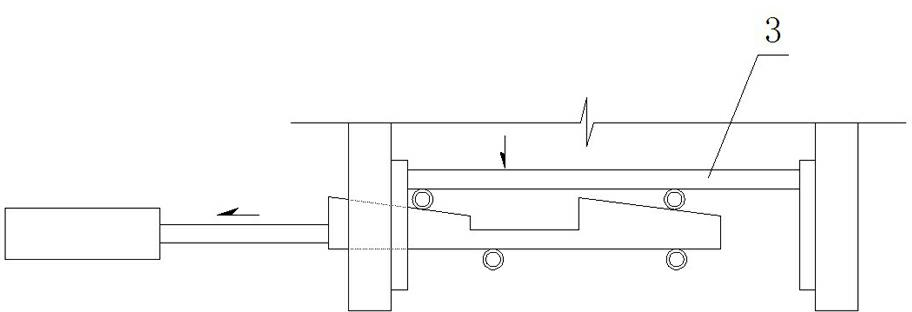

[0017] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0018] As shown in the figure, a lifting mechanism is used on a shearing and trimming machine. A cutter head for cutting product side materials is arranged above the shearing and trimming machine. During operation, the lifting mechanism is required to push the material upwards. to the blade and cut off the edge.

[0019] This jacking mechanism includes the following components:

[0020] 1) Bracket, used to set and fix other components;

[0021] 2) Pallet 3, used to place materials to be cut;

[0022] 3) Top plate 2, the top plate 2 is arranged horizontally and horizontally, and a slope 21 is provided on the left and right sides of its upper surface, and the two slopes 21 are parallel to each other and have the same size, and the lower surface of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com