Power head capable of realizing five-shaft linkage operation

A five-axis linkage and power head technology, applied in the field of robotics, can solve the problems that are not conducive to the pursuit of high stiffness/mass ratio of the mechanism, affect the fast-forward capability and dynamic performance of the mechanism, and poor bearing capacity of the mechanism, and achieve modular structure design. , Advantageous feed direction, good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the drawings and specific embodiments.

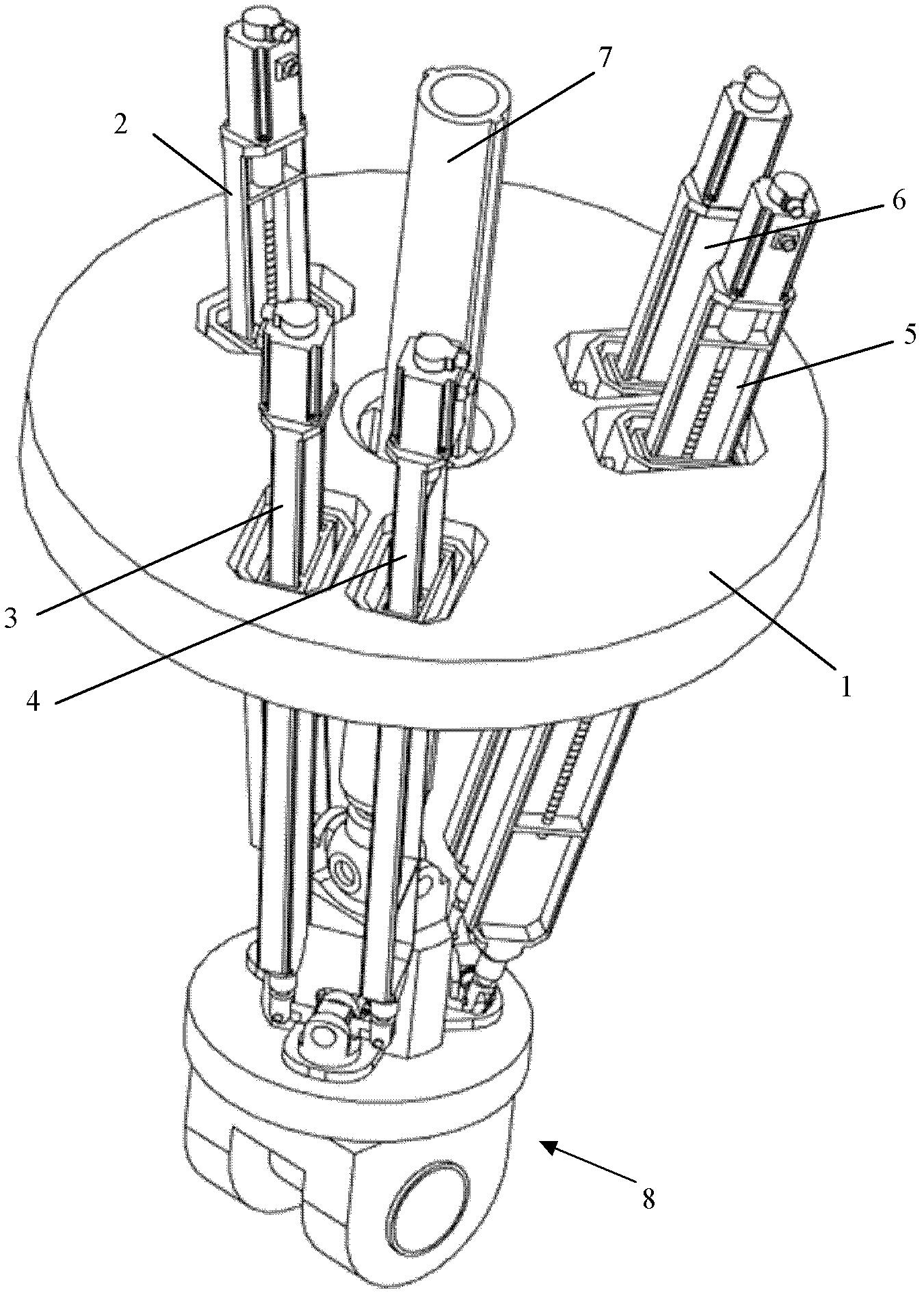

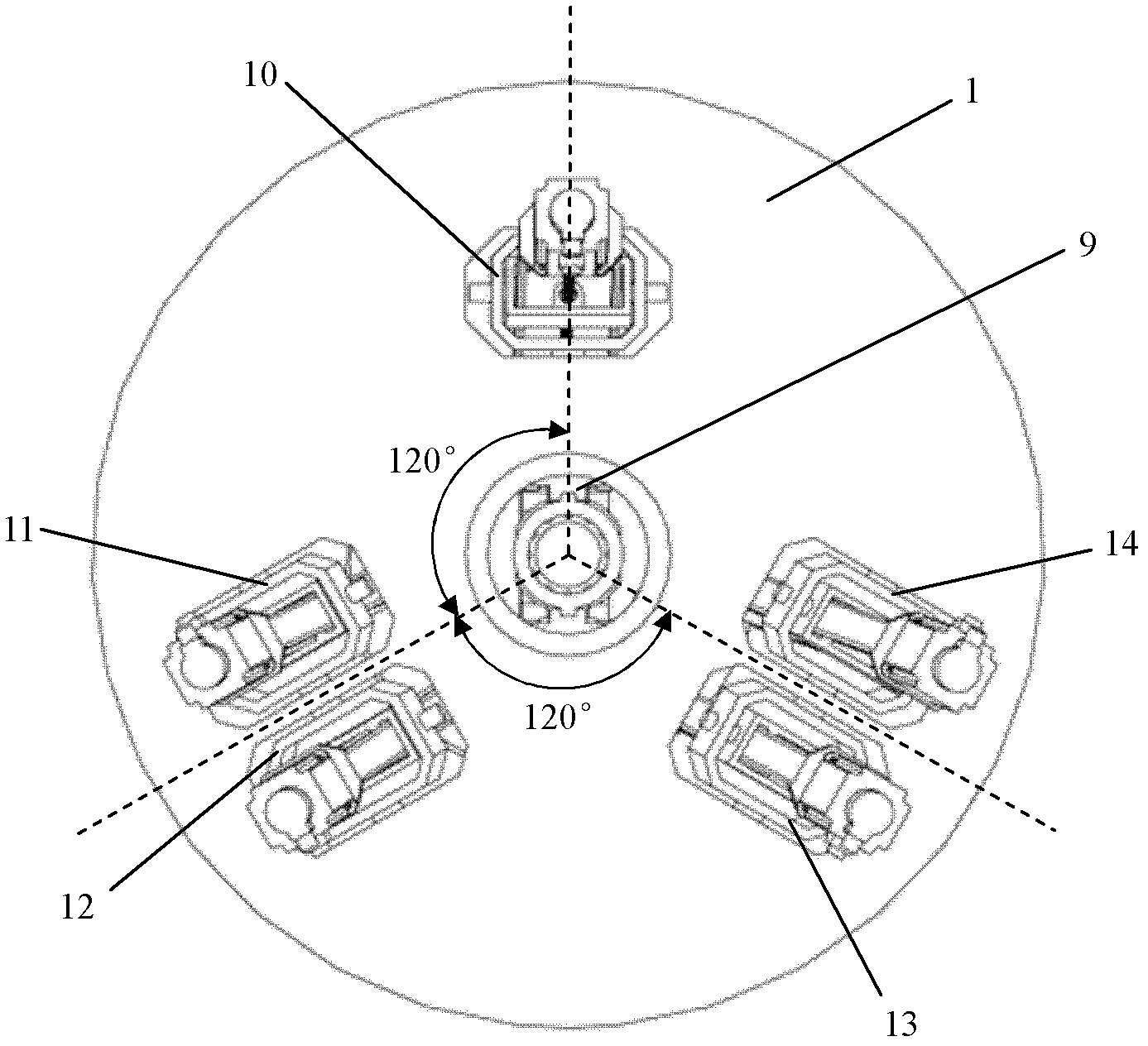

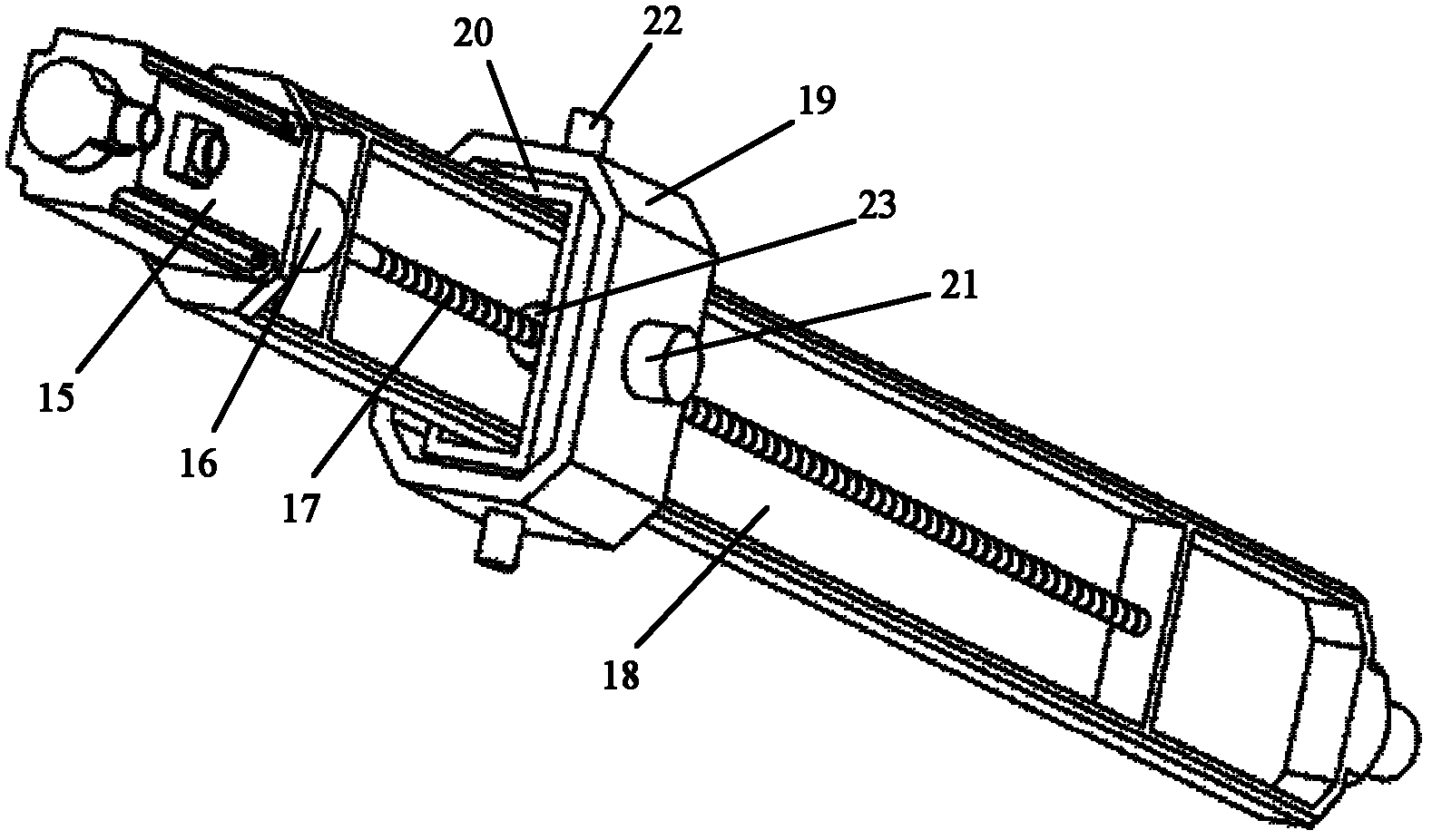

[0014] As shown in the drawings, the power head of the present invention that can realize five-axis linkage operation is composed of frame 1, first, second, third, fourth, and fifth active branch chains 2, 3, 4, 5, 6 , The driven branch chain 7 and the movable platform 8 constitute. The driven branch chain 7 is located in the central opening of the frame, and is slidably connected to the frame 1 through a first hinge 9 with a degree of freedom of movement. A first, a second, a third, a fourth, and a fifth active branch chains are respectively arranged on the frame located around the driven branch chain, and the first active branch chain 2 is a first kinematic chain, The second and third active branches 3 and 4 are second kinematic chains, and the fourth and fifth active branches 5 and 6 are third kinematic chains. Preferably, the first, second, and third kin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com