Production line for extruding optics-level transparent poly carbonate (PC) sheet

A PC sheet, optical-grade technology, applied in the field of optical-grade transparent PC (polycarbonate) sheet extrusion production lines, can solve the problems of unattainable product quality, complex extrusion production line structure, and low automation of optical-grade production lines. , to achieve uniform quality, ensure product quality, and the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

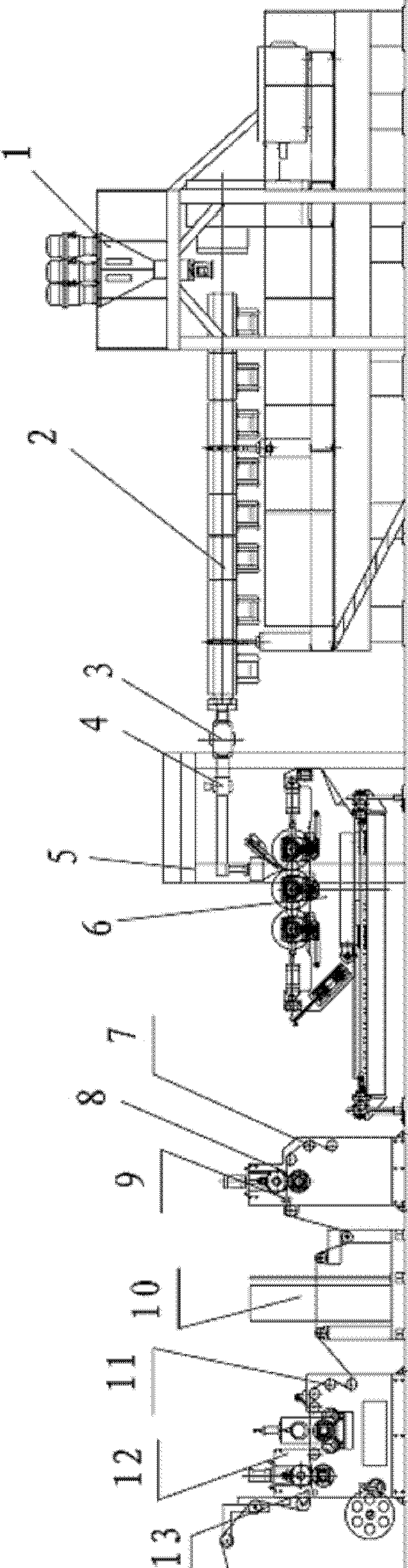

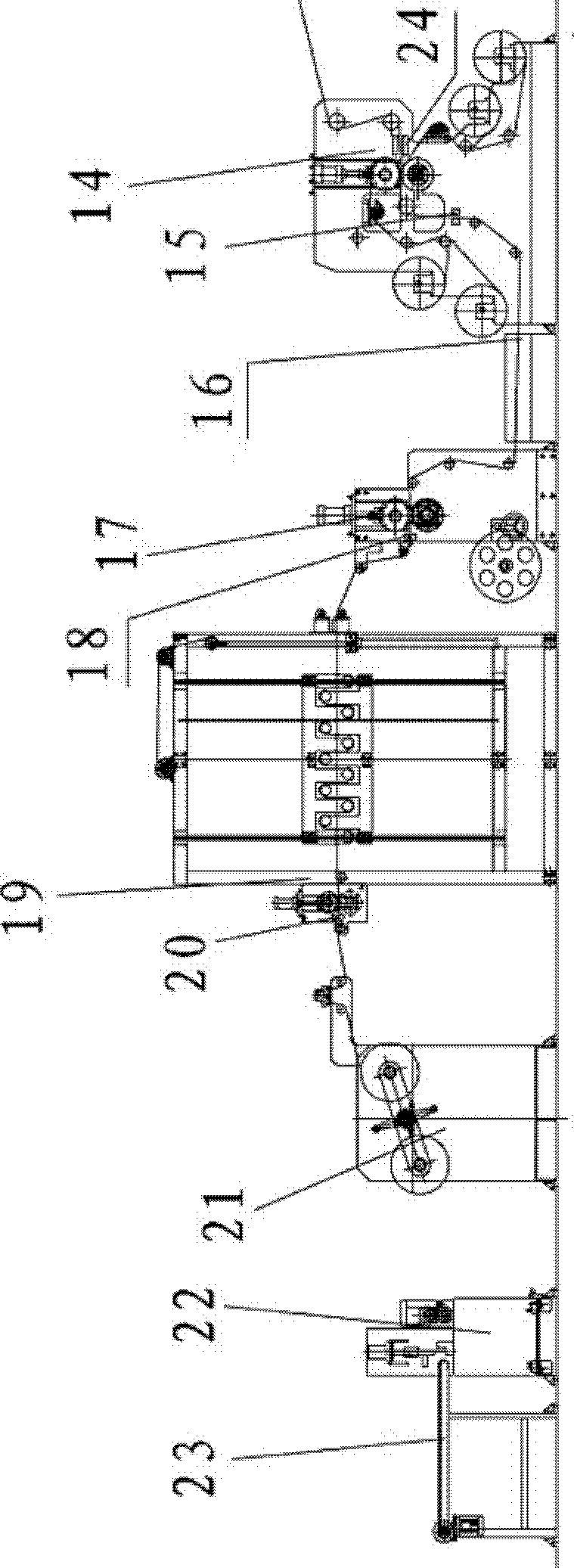

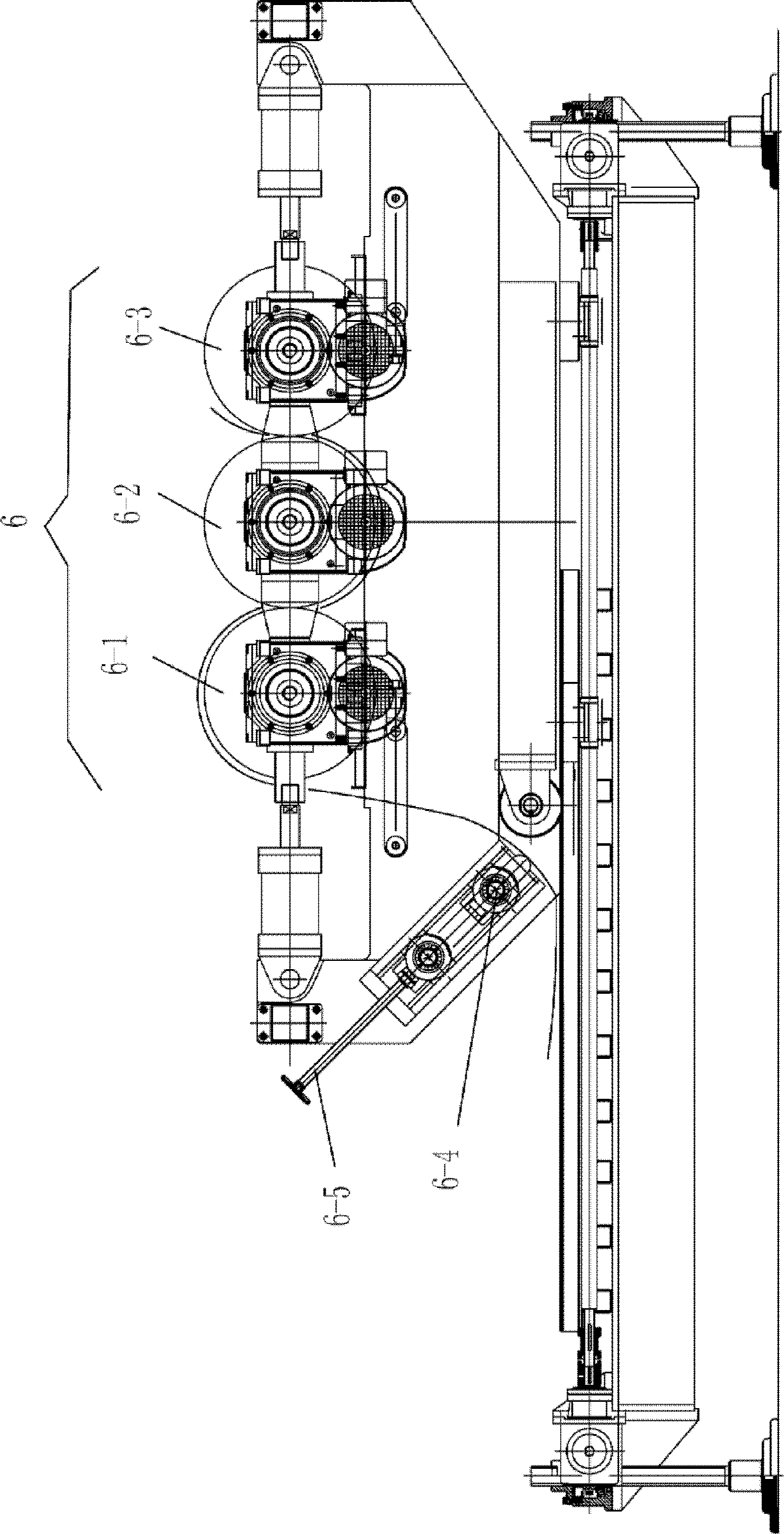

[0018] see Figure 1-6 , The optical grade transparent PC sheet extrusion production line of this embodiment includes: a drying feeding device 1, an extruder arranged at the outlet end of the drying feeding device 1 for melting solid particulate PC raw materials into a colloidal state for output 2. A filter screen 3 at the output end of the extruder 2 for filtering out impurities, a metering pump 4 located at the output end of the filter screen 3 for quantitative output of colloidal PC raw materials, and a metering pump located at the output end of the metering pump 4 for generating The molding die 5 of PC sheet, the three-roll calender 6 for smoothing the surface of the sheet set at the output end of the molding die 5, the first traction system 8 located at the output end of the three-roll calender 6, and the A thickness gauge 10 at the output end of the traction system 8 for detecting the thickness of the sheet, a second traction system 12 arranged at the output end of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com