Natural pullulan nano drug carrier and method for preparing same

A nano-drug carrier, pullulan polysaccharide technology, applied in the direction of pharmaceutical formulations, non-active ingredients medical preparations, etc., to achieve the effect of improving the therapeutic effect, good dispersion and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

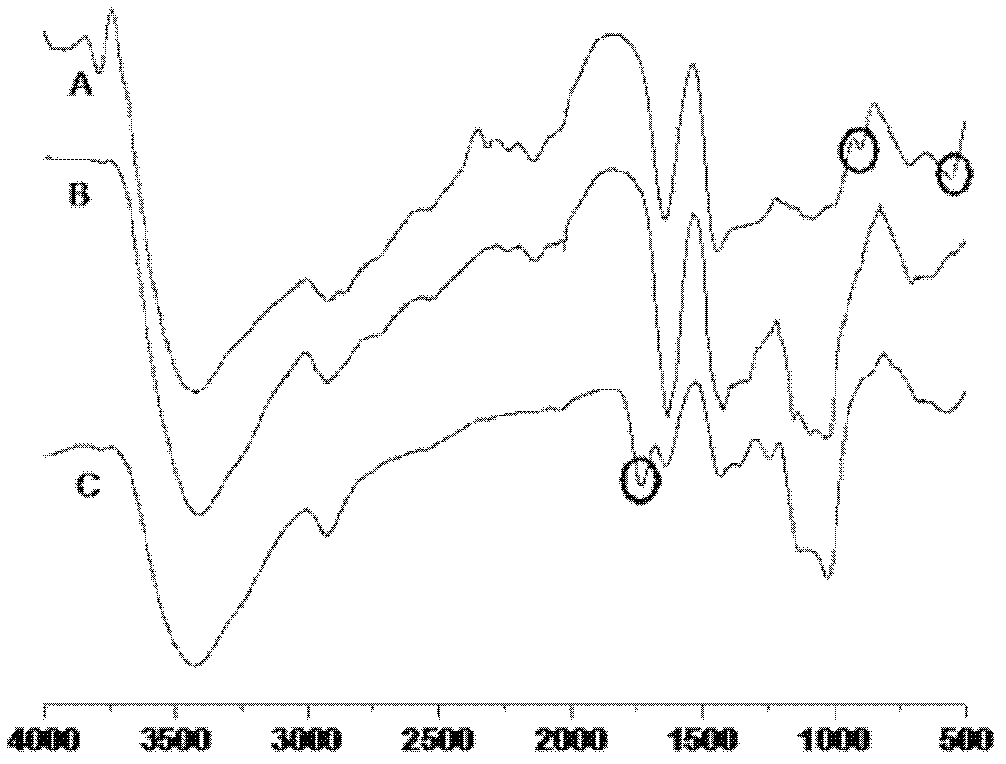

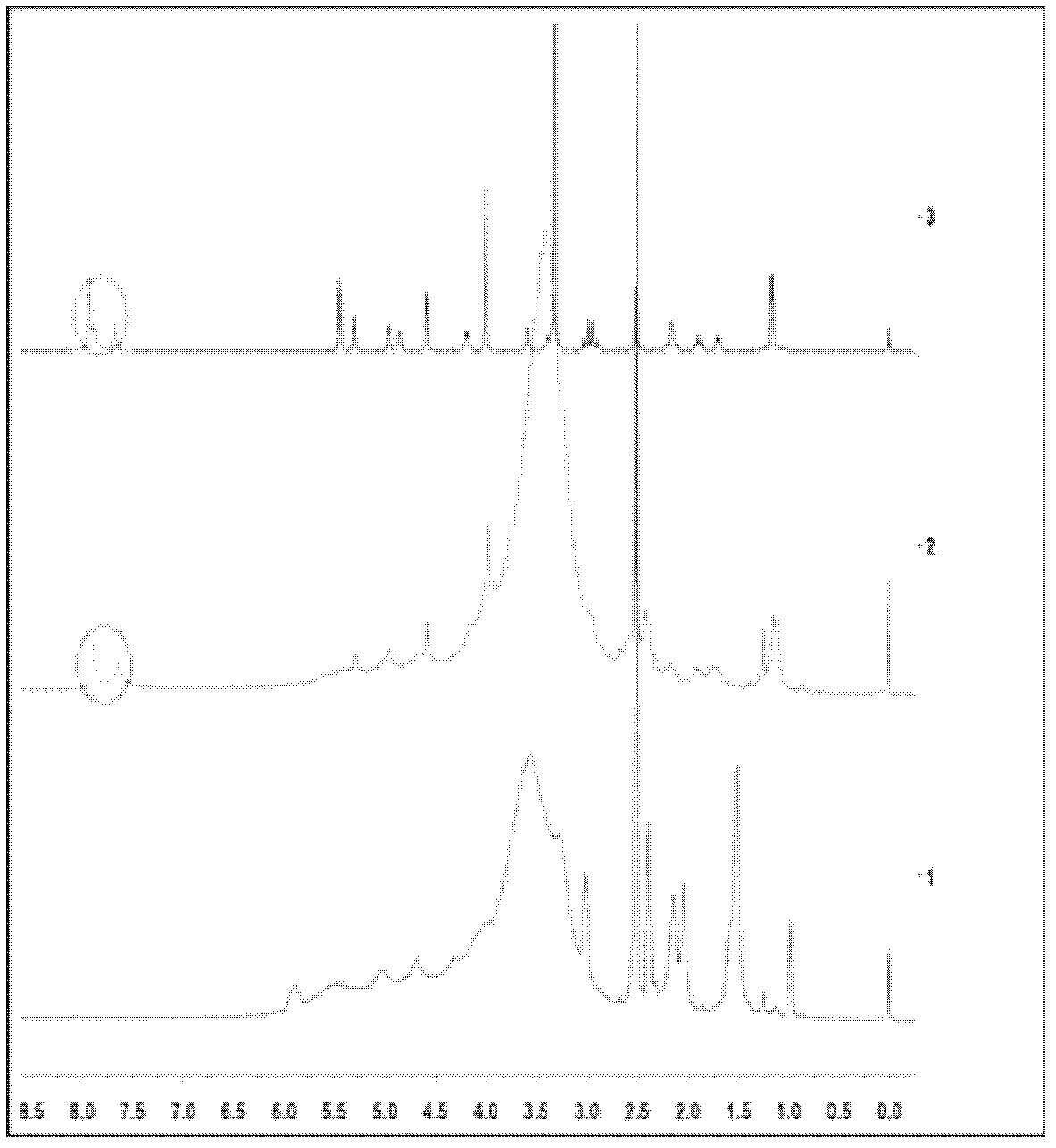

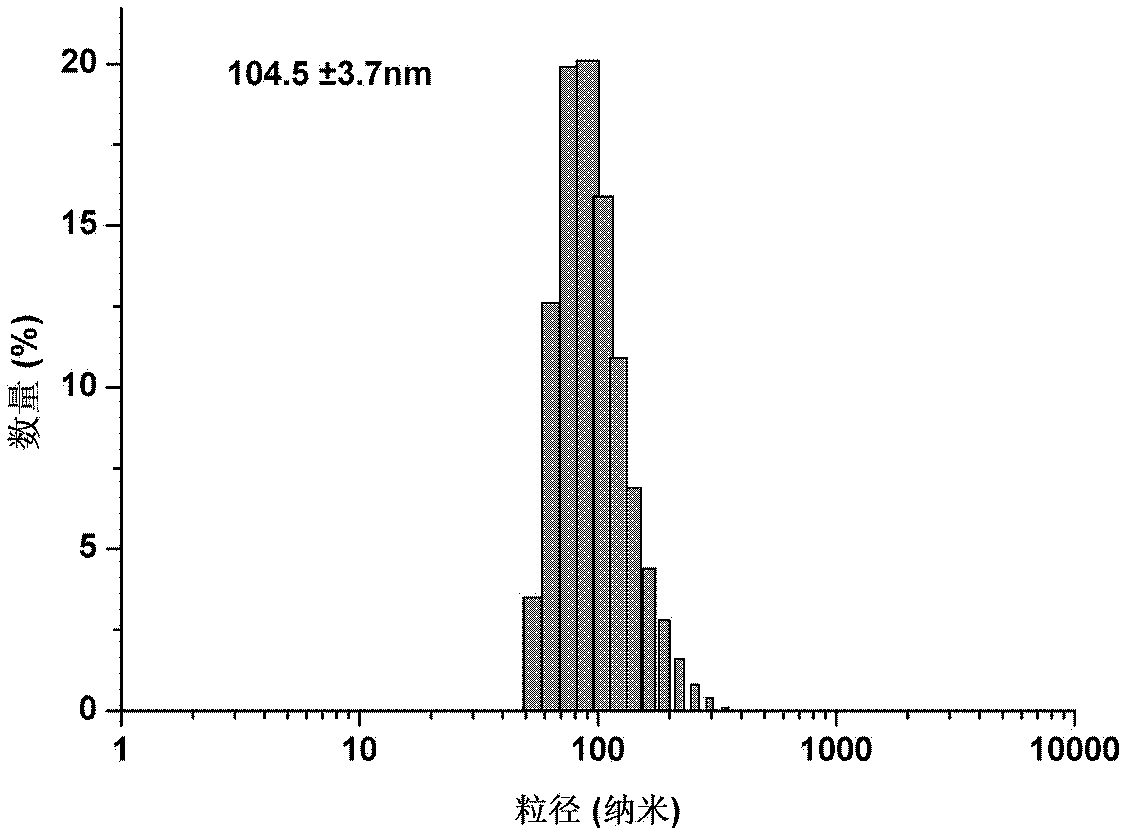

Method used

Image

Examples

Embodiment 1

[0036] The processing steps of the present embodiment are as follows:

[0037] (1) Add isopropanol to the natural pullulan aqueous solution, then add sodium hydroxide aqueous solution, stir at normal pressure and 50°C until a transparent solution is formed; the natural pullulan aqueous solution is deionized Prepared with water, the concentration is 0.1g / ml, the volume ratio of the isopropanol to the natural pullulan aqueous solution is 1:10; the sodium hydroxide aqueous solution is prepared with deionized water, the concentration is 0.1g / ml, and the hydroxide The amount of sodium aqueous solution is limited with the mol ratio=1:1 of the glucose unit of natural pullulan polysaccharide in the mixed solution and sodium hydroxide;

[0038](2) sodium chloroacetate aqueous solution and isopropanol are joined in the mixed solution prepared by step (1) simultaneously, under normal pressure, 50 ℃ of reaction 2 hours under stirring; The concentration of described sodium chloroacetate aq...

Embodiment 2

[0046] The processing steps of the present embodiment are as follows:

[0047] (1) Add isopropanol to the natural pullulan aqueous solution, then add sodium hydroxide aqueous solution, stir at normal pressure and 80°C until a transparent solution is formed; the natural pullulan aqueous solution is prepared with deionized water , the concentration is 0.5g / ml, the volume ratio of the isopropanol to the natural pullulan aqueous solution is 1:7 / 3; the sodium hydroxide aqueous solution is prepared with deionized water, the concentration is 0.5g / ml, and the hydrogenation The amount of sodium aqueous solution is limited with the mol ratio=1: 1.5 of the glucose unit of natural pullulan polysaccharide and sodium hydroxide in the mixed solution;

[0048] (2) sodium chloroacetate aqueous solution and isopropanol are joined in the mixed solution prepared by step (1) simultaneously, under normal pressure, 80 ℃ of reaction 5 hours under stirring; The concentration of described sodium chloro...

Embodiment 3

[0056] The processing steps of the present embodiment are as follows:

[0057] (1) Add isopropanol to the natural pullulan aqueous solution, then add sodium hydroxide aqueous solution, stir at normal pressure and 60°C until a transparent solution is formed; the natural pullulan aqueous solution is prepared with deionized water , the concentration is 0.3g / ml, the volume ratio of the isopropanol to the natural pullulan aqueous solution is 1:9; the sodium hydroxide aqueous solution is prepared with deionized water, and the concentration is 0.2g / ml, and the sodium hydroxide aqueous solution The amount is limited with the mol ratio=1:1.4 of the glucose unit of natural pullulan polysaccharide and sodium hydroxide in the mixed solution;

[0058] (2) sodium chloroacetate aqueous solution and isopropanol are joined in the mixed solution prepared by step (1) simultaneously, under normal pressure, 60 ℃ of reaction 3 hours under stirring; The concentration of described sodium chloroacetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com